If you hear knocking sounds in the front drive when turning the car while driving, check the constant velocity joints

If you feel any play when rocking the drive shaft by hand or the mudguards are torn, such a joint must be replaced.

Disassembling the joint is practically pointless.

This is a labor-intensive job, and if the mudguard is torn, the dirt that has gotten into the joint has already rendered the joint parts unusable.

The joint parts cannot be replaced separately, and therefore the best option is to replace the joint as a whole, as well as its mudguard.

As a last resort, disassembling the inner joint to replace the grease is allowed, as it is less susceptible to water and road dirt.

The appearance of traces of grease on the joint indicates that the mudguard torn.

You will need: a screwdriver, sliding pliers, a hammer.

Using a screwdriver and sliding pliers, remove the large clamp

Remove the small clamp from the inner joint boot.

Slide the boot along the shaft.

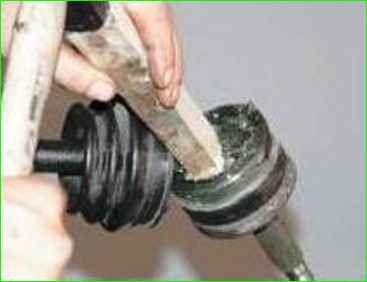

Knock the joint off the shaft with a hammer and a wooden spacer, striking the end of the collar.

To disassemble the inner joint, pry off the collar retaining ring with a screwdriver.

Remove the cage assembly with the separator and balls from the joint.

Mark the balls and the grooves of the cage in any available way to install the balls in their original places.

Using a screwdriver and pliers, remove the large and small clamps of the outer hinge boot casing.

Move the cover

Move the cover along the shaft

Knock the joint off the shaft using a hammer and a wooden spacer, striking the end of the collar

Remove from the shaft cover and casing.

Wash all metal parts with kerosene until the old grease is completely removed.

Fill the joint with SHRUS-4 grease (the amount of grease for the outer joint is 60 cm 3 for the innero – 150 cm 3);

Install the hinge and removed parts in the reverse order of removal.