Removing an automatic transmission is discussed in the article - “How to remove the automatic transmission of a Lada Granta”

Install the automatic transmission on the workbench

Replace the wheel drive seals.

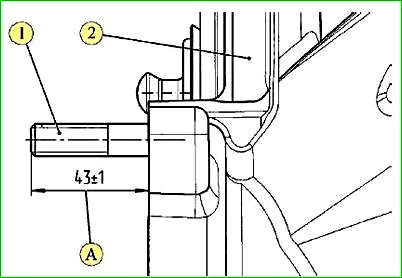

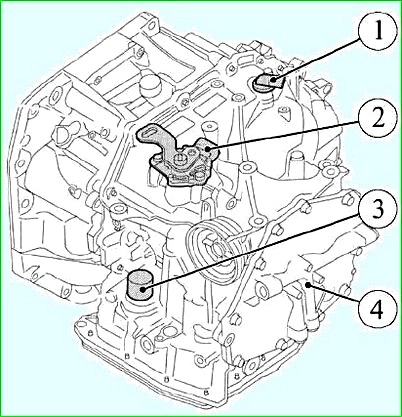

Degrease pin 1, securing the automatic transmission to the engine in the corresponding threaded hole in the torque converter housing.

Apply sealant to the threaded part of the stud screwed into the crankcase and screw the stud into the torque converter housing.

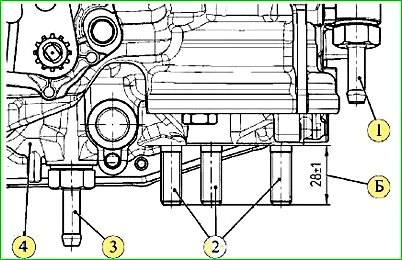

Degrease the studs 2, the fastenings of the left engine mount bracket and the corresponding threaded holes in the automatic transmission housing.

Wrap the pins to size B = 28 ± 1 mm.

Install new sealing gaskets on fittings 1 and 3 of the oil cooling system, remove the technological plugs from the holes in the automatic transmission oil line and tighten the fittings.

Tightening torque of fittings 27.2 - 33.6 Nm (2.8 - 3.4 kgm)

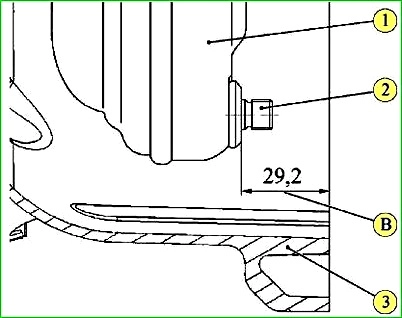

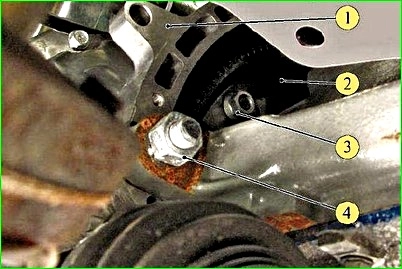

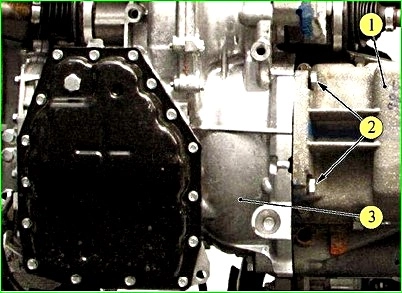

To prevent damage to the automatic transmission, before installing it on the car, make sure that the torque converter engages with the hydraulic pump of the box, for which check dimension “B”, from the plane of the mating surface of the torque converter housing 3 to the plane of the mating surface of the welded bolts 2 of the torque converter.

Make measurements at four points and calculate the average value.

If the obtained value does not correspond to dimension B = 29.2 mm, you must turn the torque converter to engage it with the automatic transmission hydraulic pump and take measurements again.

Install the automatic transmission on the transmission rack and bring it under the car.

Align the torque converter bolts with the holes on the engine drive disk, align the mounting holes on the torque converter housing and crankcase cover with the holes on the cylinder block and connect the automatic transmission to the engine.

Tighten bolt 6 with a spring washer without tightening it.

Tighten, without tightening, nut 4 with the spring washer of the stud securing the automatic transmission to the cylinder block.

Tighten, without tightening, two bolts 2, with spring washers, securing the automatic transmission to the engine crankcase.

Install the left support bracket assembled with the left engine mount onto the automatic transmission and tighten the three nuts. The tightening torque of the nuts is 20.1-32.4 Nm (2.1-3.3 kgcm).

Attach the left support to the car body and tighten, without tightening, two nuts and a bolt with a conical spring washer.

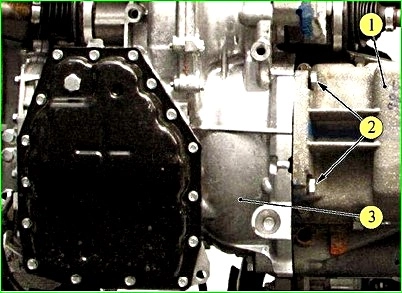

Install the rear support bracket assembled with the rear engine mount onto the automatic transmission and tighten two bolts 2, figure, with flat and spring washers. Bolt tightening torque 57-92 Nm (5.7-9.2 kgcm).

Tighten bolt 3 with a flat washer and a spring washer securing the rear engine mount bracket. Bolt tightening torque 32-52 Nm (3.2-5.2 kgcm).

Attach the rear support to the car body and tighten the two fastening nuts without tightening them.

Tighten the bolt and nut securing the automatic transmission to the cylinder block. Torque bolts and nuts 55-87 Nm (5.5-8.7 kgcm).

Tighten the two bolts securing the automatic transmission to the engine crankcase. Bolt tightening torque 34-53 Nm (3.4-5.3 kgcm).

Tighten the two nuts and bolt securing the left engine mount. Tightening torque 33-51 Nm (3.3-5.1 kgcm).

Alternately, turning the engine crankshaft, tighten the four nuts securing the torque converter to the engine drive disk. The tightening torque of the nuts is 44-58 Nm (4.4-5.8 kgcm).

Reinstall the torque converter housing cover plug and secure with two bolts. Bolt tightening torque 4.8-7.8 Nm (0.5-0.8 kgcm).

Remove the stands from under the engine and automatic transmission and lower the car.

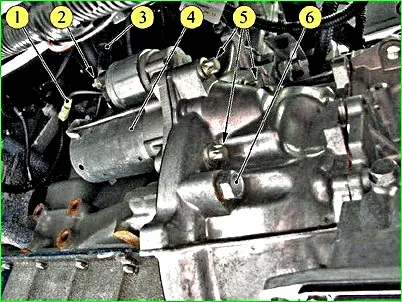

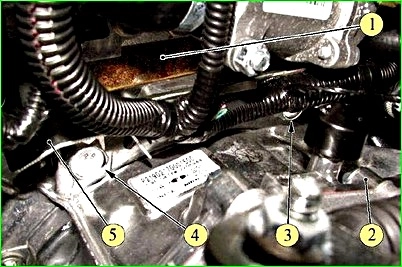

Install bracket 5, fastening the wiring harness and tighten two bolts 3 and 4 with spring washers securing the automatic transmission to the cylinder block. Bolt tightening torque 55-87 Nm (5.5-8.7 kgf.m).

Raise the car.

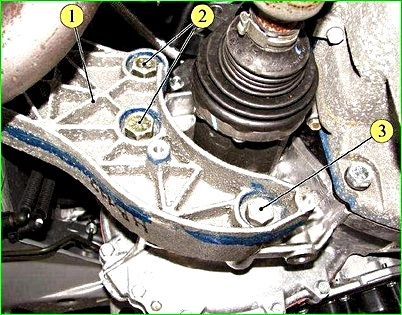

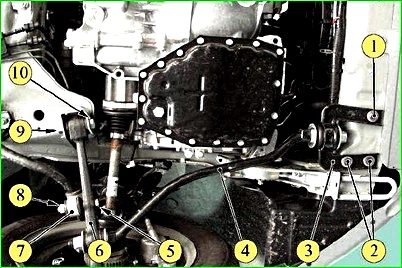

Install the left lower front suspension arm with the ball pin, brace and brace bracket assembly.

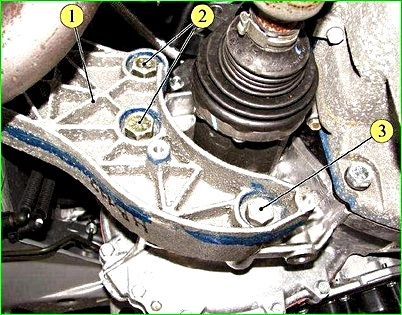

Fix the brace bracket to the body with two bolts 2, with flat washers and one bolt 1 with a flat washer. Bolt tightening torque 58-70 Nm (5.8-7.0 kgf.m).

Connect the front suspension arm to the body bracket.

Insert the fastening bolt and tighten without tightening the nut and spring washer.

Install the front wheel drives, install washers and screw on the hub nuts, connect the ball pins to the steering knuckles and reinstall the heat shield of the right wheel drive joint.

Attach the strut 7 of the anti-roll bar to the left lower arm 6 of the suspension, install bolt 5 and screw in, without completely tightening, nut 8 with a spring washer.

Install the starter and secure it with three bolts. Bolt tightening torque 18-24 Nm (1.8-2.4 kgf.m).

Connect the front wiring harness to the starter solenoid relay terminal. The tightening torque of the nut is 10-13 Nm (1.0-1.3 kgf.m).

Connect the front wire harness block to the starter solenoid relay wire block.

Remove the technological plugs from the fittings and pipes of the automatic transmission oil cooling system, connect the pipes to the fittings and secure them with clamps.

Install the middle and right engine mudguards in place, and secure with self-tapping screws and serrated washers.

Install the left front fender flap.

Install the front wheels.

Lower the car.

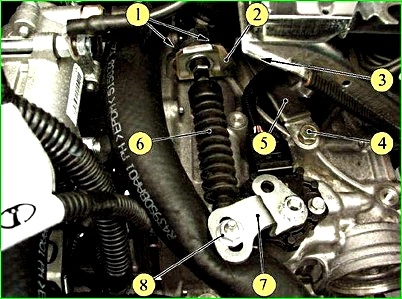

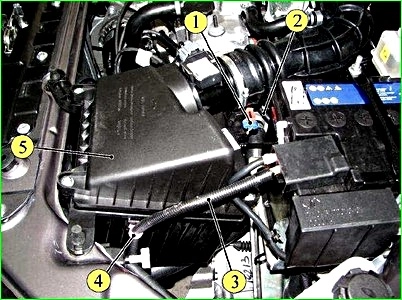

Install bracket 5 on the automatic transmission housing, fastening the wiring harness and secure it with bolt 4 (M10x22) with a spring washer and bolt 3 (M6x14). Bolt tightening torque (M10x22) 32-52 Nm (3.2-5.2 kgf.m). Bolt tightening torque (M6x14) 4-6 Nm (0.4-0.6 kgf.m).

Install the gear selection cable mounting bracket assembled with the cable onto the torque converter housing and secure it with two bolts. Bolt tightening torque 12-19 Nm (1.2-1.9 kgf.m).

Set lever 7 of the driving mode selection mechanism, rotating it counterclockwise, and the gear shift lever to the extreme forward position in the direction of travel of the car.

Install the cable end into the groove of the lever and tighten the fastening nut. The tightening torque of the nut is 21-25 Nm (2.1-2.5 kgf.m).

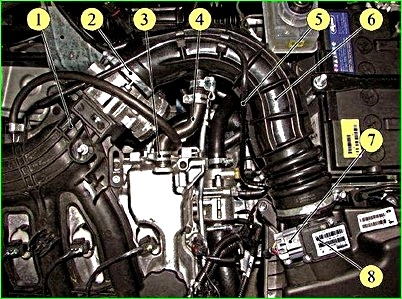

Connect the front wiring harness block to sensor 1, output shaft speed.

Connect the front wiring harness connector to the drive mode selection mechanism 2 connector.

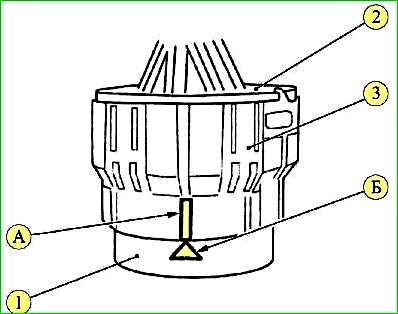

Connect block 2 of the front wiring harness to the 22-pin connector of the automatic transmission.

Turn the locking ring 3 of the pad clockwise until the slot “A” coincides with the mark “B”.

Attention. Do not confuse slot “A” with each other them as structural elements of the locking ring.

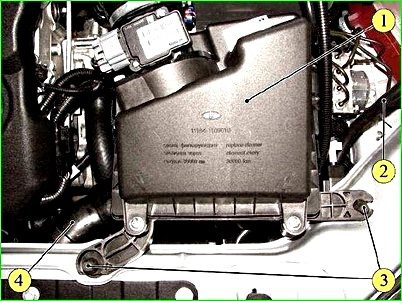

Attach the radiator steam pipe 2 to the air filter housing 1 using a bracket.

Install the air filter with the mass air flow sensor and the intake pipe hose assembly onto the three mounting supports 3 and attach the air intake pipe 4 to the air filter housing.

Attach front wire harness 3 to air filter housing 5 using bracket 4.

Attach the connector of steam exhaust tube 2 to the adsorber valve.

Connect block 1 of the ignition system wiring harness to the canister valve.

Attach block 7 of the ignition system wiring harness to mass air flow sensor 8.

Connect the connector of tube 5 of the canister valve to electronic module 1 of the intake.

Attach hose 6 of the intake pipe to the electronic module 1 of the intake and tighten the clamp 2 of the fastening.

Place the upper hose 4 of the crankcase ventilation onto the pipe of the cylinder head cover and tighten the clamp 3.

Install the engine soundproofing screen.

Connect the earth wire terminal to the battery.

Attention. In case of replacing the automatic transmission or transmission control unit or replacing the automatic transmission and control unit at the same time, it is necessary to calibrate the transmission control unit in accordance with the requirements of TI 3100.25100.12049.

Fill the automatic transmission with oil in accordance with the requirements of the article “How to check and change the oil in the Lada Granta automatic transmission.”

Put the car on the lift, brake with the parking brake and raise to a height convenient for work.

Press the front suspension by hand 2-3 times to self-install its components, applying a force of 400-500 N (40-50 kgf) in the area of the front bumper.

Finally tighten the nuts securing the components and parts of the front suspension. Tightening torques:

- nuts, bolts securing the lower suspension arm to the body bracket 79-96 Nm (7.9-9.6 kgf.m);

- bolt nuts, securing the stabilizer strut to the lower left arm of the front suspension 43-52 Nm (4.3-5.2 kgf.m)

Check and, if necessary, adjust the angles of the front wheels.