Knock sensor - piezoelectric, reacts to engine vibration

Using sensor signals, the ECU determines the moment when detonation occurs during engine operation and, in accordance with this, adjusts the ignition timing.

If the knock sensor malfunctions, the electronic control unit switches the system to backup mode.

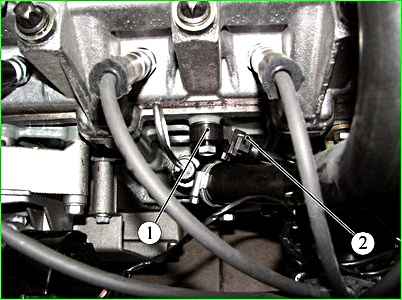

The knock sensor is installed on the front wall of the cylinder block in the upper part.

Disconnect the negative terminal of the battery

Press the spring clip of the wiring harness block and disconnect the block from the sensor.

Unscrew the bolt securing the sensor to the cylinder block and remove the sensor

Attach an autotester connected in voltage measurement mode to the sensor terminals.

Tap the sensor body against a solid, massive object (for example, a hammer).

In this case, the voltage should change.

If the voltage remains constant, the sensor is faulty and needs to be replaced.

More accurately, the serviceability of the sensor can be checked while the engine is running using the DST-2 diagnostic tool.

Install the sensor in the reverse order of removal

If the malfunction persists, check the quality of the fuel (change the fuel) and spark plugs.