Tie rod joints are replaced if play appears

It is more convenient to carry out work in an inspection ditch

The transverse link can be replaced as an assembly, or separately its ends or their hinges.

If the fasteners are very dirty, clean them with a wire brush and treat them with a penetrating lubricant such as WD-40.

Using pliers, unscrew the nut securing the transverse link

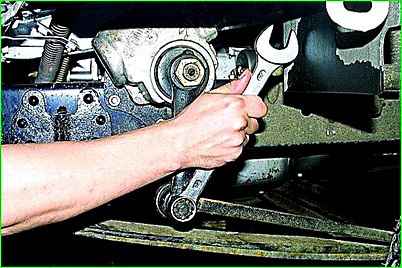

Using a 24mm wrench, unscrew the nut securing the transverse link to the lever. The nut should be left on the thread of the pin.

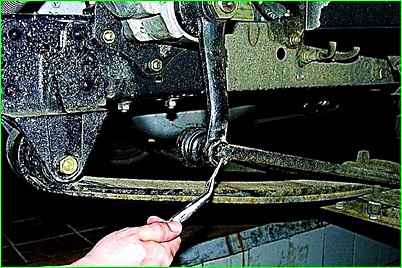

Using the rotary lever as a support, we “strain” the finger, resting the mounting blade on the transverse rod.

Hit the lever with a hammer and press out the finger.

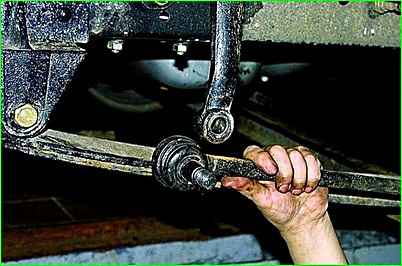

After unscrewing the nut, remove the pin from the hole in the transverse rod.

Loosen the tension of the rod clamp. By rotating the tip, we turn it out of the steering rod.

To replace the hinge, pry up the seal with a screwdriver or a thin chisel

Remove the seal.

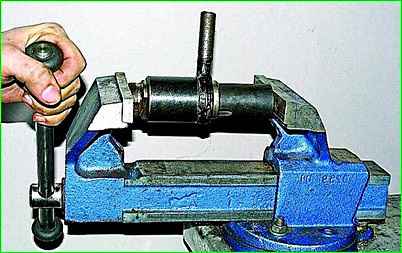

We select (make) two mandrels from pipes of suitable diameter.

One with a hole slightly larger than the diameter of the hinge body, and the second with an outer diameter equal to the diameter of the hinge.

Place a mandrel under the hinge and clamp the tip in a vice.

Tightening the vice, press the hinge body out of the rod end through the second mandrel.

Install the new hinge into the hole in the rod.

We press the new hinge through the mandrel, resting the tip against a pipe of a suitable diameter and length

Can be pressed in a vice

Put ShRB-4 grease into the joint seal, put it in place and wrap the assembled tip into the rod.

When replacing the tip assembly, do not press out the hinge, but immediately screw the new one into the rod.

We similarly replace the hinge or tip on the other side of the rod.

The tips of the right and left sides are not interchangeable, since they have threads in the opposite direction.

Install the tie rod in the reverse order, covering the hinge pins with any lubricant.

After installing the linkage, we adjust the toe-in of the front wheels.

To replace the longitudinal link joints, use pliers to unscrew the nut

Use a 24mm wrench to unscrew the nut securing the longitudinal link to the bipod.

Pressing the rod away from the bipod with a mounting paddle and hitting the bipod boss with a hammer on the side, presses out the pin

You can use a special puller to press out your finger

Disconnect the longitudinal link from the bipod.

In the same way, disconnect the longitudinal rod from the swing arm.

Repress the hinges of the longitudinal steering rod in the same sequence as for the transverse rod or replace the rod assembly.

Install the new link in the reverse order, lubricating the conical surfaces of the pins with any lubricant.