We carry out repairs to the cylinder head during general engine repairs and when replacing the cylinder head gasket

It is very important to repair the head after the motor has overheated.

During overheating, defects may occur that may not be visible visually

Therefore, you need to carefully carry out all operations to repair the cylinder head.

The operation of the engine largely depends on this. And this will save you from unnecessary work and costs.

We look at removing the cylinder head in the article - Cylinder head gasket ZMZ 405 GAZ-2705

Disassembling the cylinder head

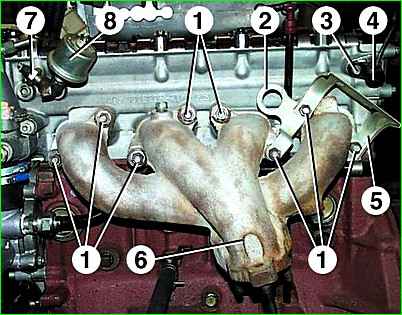

Unscrew nuts 1 and remove screen 5 of the phase sensor, bracket 2 for lifting the engine and exhaust manifold 6.

Remove the exhaust manifold gaskets.

Unscrew bolt 3 and remove the 4th phase sensor.

Unscrew the emergency oil pressure sensor 7 and the oil pressure indicator 8.

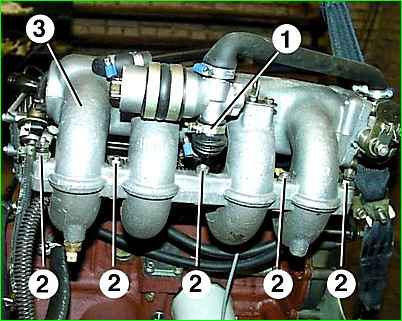

Loosen clamp 1 and remove the hose from the idle air regulator pipe.

Unscrew nuts 2 and remove receiver 3 from the inlet pipe.

Remove the receiver gasket.

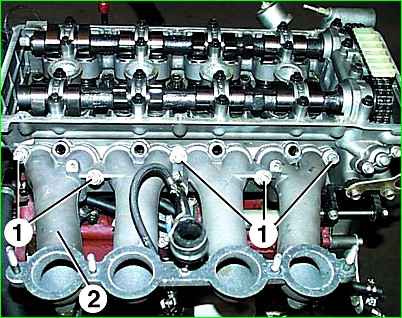

Unscrew nuts 1 and remove intake pipe 2 along with injectors and fuel line (not shown in the photo).

Remove the intake pipe gasket.

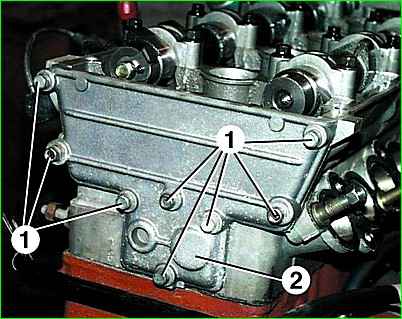

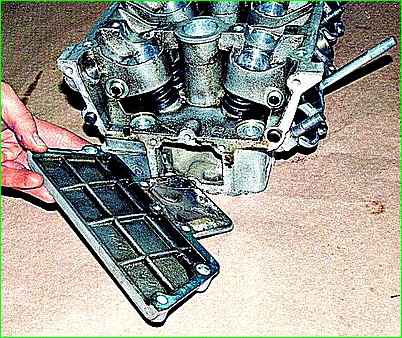

Unscrew bolts 1 and remove rear cover 2 of the block head.

Remove the cover gasket

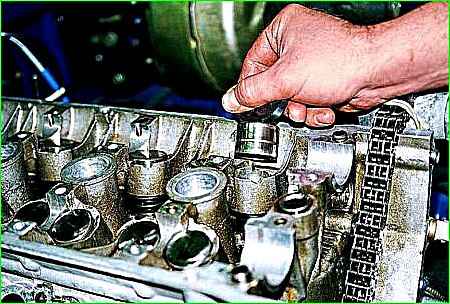

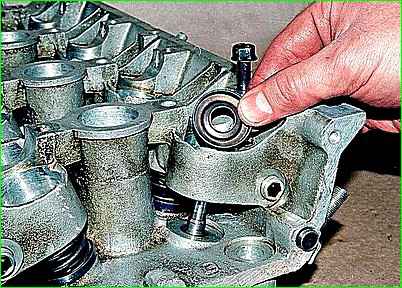

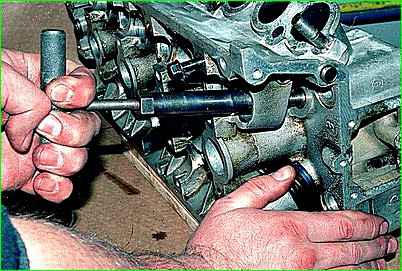

Remove hydraulic valve lifters 1. It is more convenient to remove hydraulic pushers using a magnet or suction cup

Hydraulic pushers cannot be swapped, so before removal they must be marked so that they can be installed in their place during assembly.

Hydraulic lifters should be stored in the same position as they are on the valves, so that oil does not leak out of them.

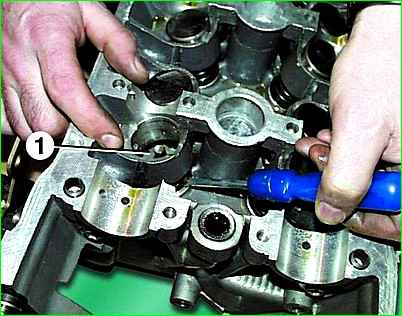

If the design of the puller does not provide a valve stop, place a suitable stop under it.

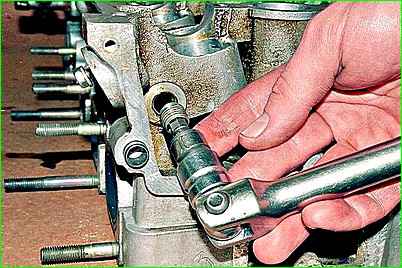

Compress the springs with a desiccant.

To make the spring plate easier to remove from the crackers, you can apply a light blow with a hammer to the persistent bipod of the desiccant.

Use tweezers to remove two crackers and smoothly release the springs.

Remove the upper plate and two valve springs.

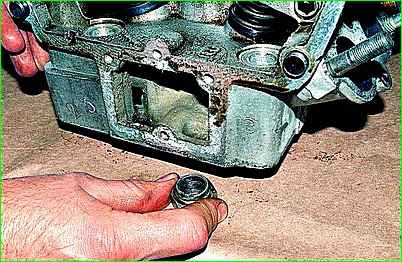

Use a puller to remove the oil cap...

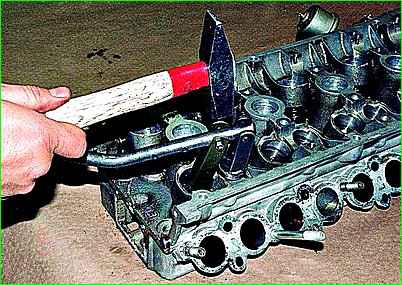

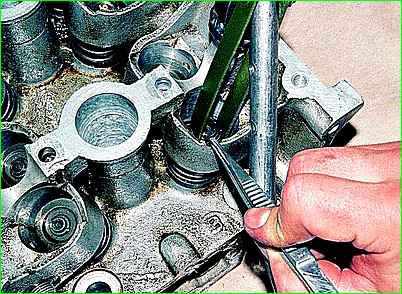

Use a screwdriver and remove the support washer 1 of the valve springs.

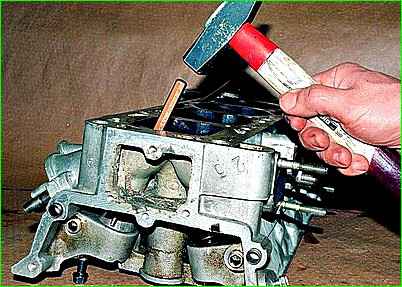

Turn over remove the cylinder block and remove the valve, marking its installation location so that during subsequent assembly the valve will return to its original place. Similarly, we remove and mark the remaining valves.

We press out worn valve guides with a mandrel

Use an “8” hex wrench to unscrew the oil channel plugs

Inspection, troubleshooting and repair of the cylinder head

After disassembling the cylinder head, wash all parts in gasoline, wipe and dry. Clean combustion chambers and valves from carbon deposits.

Inspect the block head.

If there are cracks on the bridges between the valve seats, burn marks and cracks on the walls of the combustion chamber, replace the cylinder head.

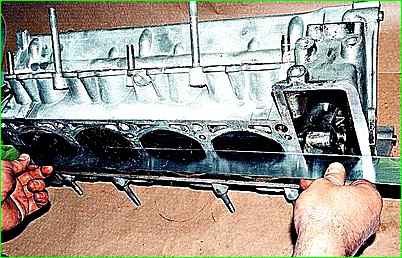

Check using a metal ruler and feeler gauges to see if the flatness of the surface of the head adjacent to the block is broken.

To do this, place the ruler with its edge on the surface of the block head, in the middle, along and then across, and use a feeler gauge to measure the gap between the surface of the head and the ruler. If the gap exceeds 0.1 mm, replace the head.

Check the clearances in the camshaft bearings.

Check the gaps between the hydraulic valve lifters and the channels for the hydraulic lifters in the cylinder head.

The gap is calculated as the difference between the diameter of the channel and the diameter of the hydraulic pusher.

The nominal diameter of the channel for the hydraulic pusher is 35.0 +0.025 mm, the maximum permissible is 35.1 mm.

The nominal diameter of the hydraulic pusher is 35.0 -0.025 and 35.0 -0.041 mm, the maximum permissible diameter is 34.95 mm. The maximum permissible gap is 0.15 mm.

If the gap exceeds the specified value, replace the hydraulic tappet. If this does not give a positive result, replace the block head.

Inspect the valves.

If cracks, warping of the valve head, burnout, or deformation of the stem are detected on the working face of the valve, the valve must be replaced.

Minor marks and scratches on the working face of the valve can be removed by lapping.

The valve is ground into the seat as follows:

- - insert the valve into the block head;

- - put a valve grinding device on the valve stem;

- - apply a thin layer of lapping paste, which is a mixture of fine abrasive powder with engine oil, to the working chamfer of the valve;

- - turn the valve using the device in both directions, periodically pressing it against the seat.

An external sign of satisfactory lapping is the uniform matte gray color of the working chamfer of the seat and valve.

After lapping, wipe the seat and valve with a clean cloth and rinse thoroughly to remove any remaining lapping paste.

To check the tightness of the valve, install it in the block head along with springs and cotters.

After this, place the block head on its side and pour kerosene into the channel closed by the valve. If within 3 min. kerosene will not leak into the combustion chamber, the valve is considered sealed.

Check the condition of the valve springs. Springs that are bent, cracked or broken must be replaced.

Check the condition of the valve seats. The working chamfers of the seats should not show signs of wear, holes, corrosion, etc.

Minor damage (small marks, scratches, etc.) can be removed by grinding in the valves.

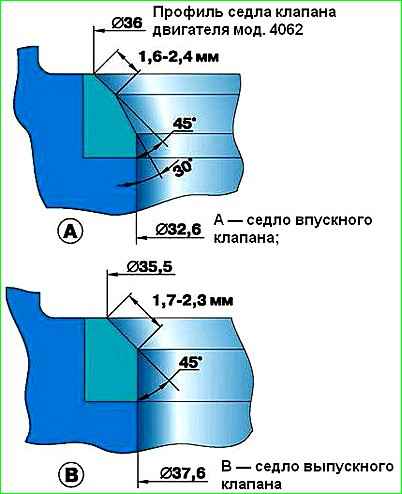

More significant defects can be eliminated by grinding. When grinding, maintain the seat dimensions indicated in the figure

After grinding, check the runout of the seat chamfer relative to the hole in the valve guide, the maximum permissible runout is 0.05 mm.

After grinding, grind the valves.

Then thoroughly clean and blow out the cylinder head with compressed air so that there are no abrasive particles left in the channels closed by the valves and in the combustion chambers.

It should be noted that after grinding the seat, the valve sits deeper in the seat.

Therefore, after grinding, you need to measure the distance between the end of the valve stem pressed against the seat and the camshaft axis.

If this distance is less than 35.5 mm, replace the cylinder head, since in this case the normal operation of the valve lifters is disrupted.

Check the gaps between the guide bushings and valves.

The gap is calculated as the difference between the diameter of the hole in the bushing and valve stem diameter. The maximum permissible gap is 0.2 mm.

If the gap exceeds the specified value, replace the valve and guide sleeve.

The old bushing is pressed out using a mandrel from the side of the combustion chamber.

Install new bushings with retaining rings put on them until the retaining ring stops in the plane of the block head on the side of the hole for the hydraulic pushers.

Before installation, the bushings must be cooled to –40...45°C, and the block head must be heated to a temperature of +160-175°C.

The bushing should be inserted into the block head freely or with little force.

Valve guides are supplied as spare parts in three repair sizes.

The first repair size with the outer diameter of the bushing increased by 0.02 mm.

The second is the outer diameter of the sleeve 14.2 +0.053 and 14.2 +0.040 mm, the third is with a diameter increased by 0.02 mm from the second size.

When installing bushings of the first repair size, do not bore the hole for the bushing in the block head.

When installing bushings of the second and third repair sizes, you need to bore the hole to a diameter of 14.2 -0.023 and 14.2 -0.050 mm.

After installing the new bushings, expand the hole for the valves in them to the dimensions indicated in the table. 2.1. Then grind the valve seats as indicated above.

In order to check the block head for cracks, you need to connect a compressed air hose to one of the holes in the cooling jacket.

Plug all holes in the head with wooden plugs. Lower the head into a bath of water and apply compressed air at a pressure of 1.5 atm. In places where there are cracks, air bubbles will come out.

Having cleaned the mating plane of the head, we check the quality of the fit of the head to the block with a straight edge.

If the deformation exceeds 0.05 mm, the flatness must be restored by mechanical treatment, however, if the non-flatness exceeds 0.1 mm, the head is not repaired.

Use kerosene or diesel fuel to rinse the head and clear the oil channels of deposits.

Then we wipe the surfaces with a clean rag and blow out the channels with compressed air. Replace the oil channel plugs

We press new valve bushings through an aluminum spacer, preheating the head to 160–180°C and cooling the bushings in “dry ice” (CO 2).

Install the valves in the reverse order of removal, replacing the old oil seals with new ones

Lapping in valves

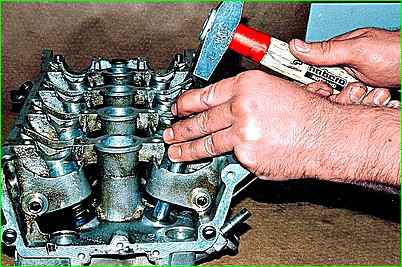

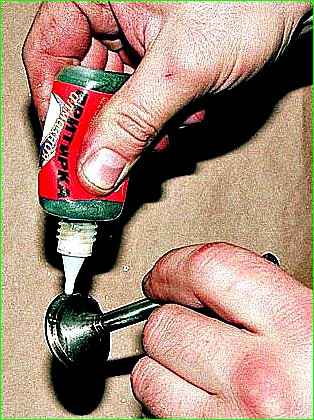

Apply lapping paste to the valve chamfer and install it in the corresponding head bushing.

Attach a lapping device to the valve stem and, pressing the valve against the seat, turn it in both directions by approximately 90°

We continue grinding until the valve sealing chamfer along its entire width and length becomes matte and clean.

The chamfer on the valve seat should also look like this. Wipe off any remaining paste from the valve and seat with a rag.

Assemble the cylinder head in reverse order.