Drain the oil from the engine. We wash the engine and install it on a disassembly stand or stand

If possible, work on a special turntable that provides access to the engine from all sides, as it is very difficult to fix the engine from moving when unscrewing fasteners tightened with a large torque.

Remove the engine from the car.

Put the engine on solid supports.

Disconnect the gearbox from the engine.

Remove the cylinder head (see "Replacing the cylinder head gasket").

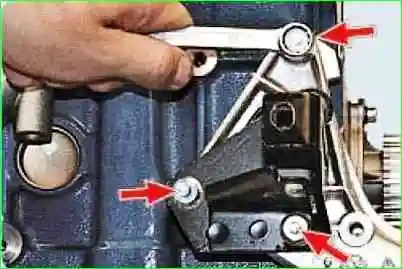

Using a 13 wrench, remove the three bolts securing the front support bracket of the power unit to the cylinder block

Remove the bracket.

Remove the oil filter.

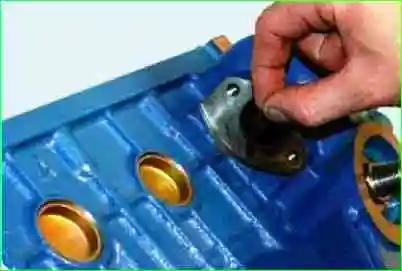

Using a 10 wrench, unscrew the two bolts securing the coolant pump supply pipe to the cylinder block ...

Remove the pipe

Remove the gasket.

When assembling the engine, install a new seal

Remove the water pump and seal.

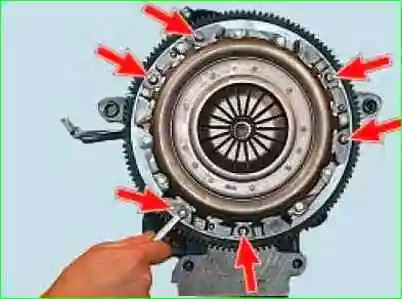

Using an 8 wrench, remove the six bolts securing the clutch to the flywheel

Remove the clutch.

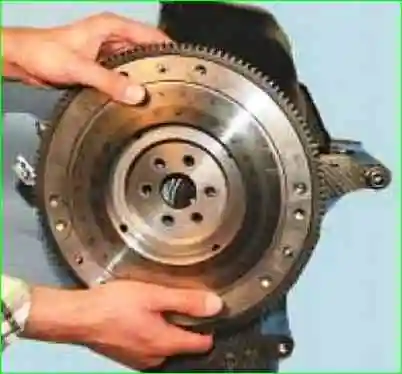

Mark the relative position of the flywheel and the crankshaft.

With a 17" socket, remove the six flywheel mounting bolts

Remove the flywheel

Using a 10 wrench, unscrew the sixteen bolts securing the oil sump

Remove the oil pan along with the seal.

Using a 10 wrench, unscrew the three bolts securing the oil receiver

Remove the oil receiver.

Please note: in the groove of the receiver nozzle, a cut New O-ring.

Be sure to replace a severely compressed, hardened or torn ring.

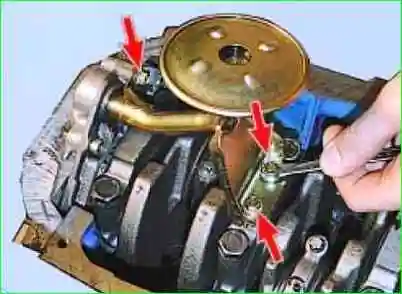

Pry off with two screwdrivers

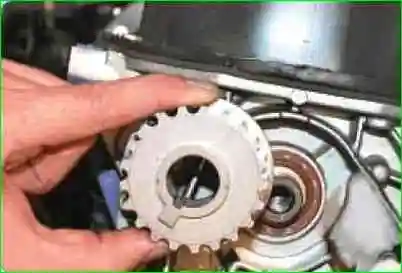

Remove the toothed pulley from the toe of the crankshaft

Remove the key from the groove on the toe of the crankshaft.

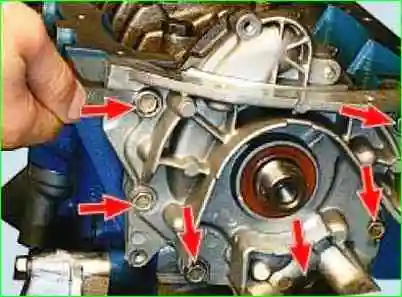

Using a 10 wrench, remove the six oil pump mounting bolts and remove the pump.

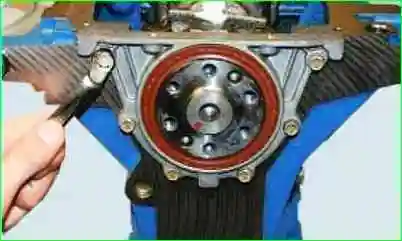

Using a 10 wrench, remove the six bolts securing the crankshaft rear oil seal holder

Remove the holder with the oil seal installed in it

Remove the gasket.

Turn the crankshaft so that the piston to be removed is at BDC (bottom dead center).

Using a TORX E10 wrench, remove the two connecting rod cap bolts.

Remove the connecting rod cap.

If it is difficult to remove the cover, first remove it with light blows of a hammer.

The cylinder number on the cap may not be visible, in which case mark the cap with the cylinder number.

Push the connecting rod inside the cylinder with a hammer handle

Carefully remove the piston with connecting rod from the cylinder.

When doing this, make sure that the lower head of the connecting rod does not touch the mirror of the cylinder, otherwise the mirror may be damaged.

Remove the rest of the pistons in the same way.

If you are going to remove the piston from the connecting rod, mark the piston with the cylinder number so as not to mix up the pistons during installation.

On the connecting rod, as well as on the cover, the cylinder number is stamped; if it is not visible, mark the connecting rod.

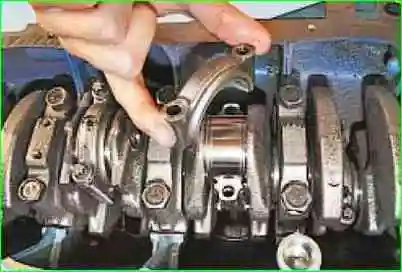

Using a 17" wrench, remove two bolts securing the five main bearing caps

Remove covers.

The main bearing caps are marked with notches according to the cylinder numbers.

If these marks are not clearly visible, be sure to additionally mark the covers in order to reinstall them in their original places: the covers are not interchangeable (the cylinder block is machined together with the covers).

Remove the crankshaft.

Remove the thrust half rings installed in the grooves of the middle bearing of the crankshaft.

Remove the liners from the main bearing caps

Remove the block bed liners.

If you do not intend to replace the liners, when removing, mark the liners on the non-working side with respect to covers and beds.

Remove the piston rings with a special tool.

If it is not there, remove the rings from the piston by carefully spreading the ring locks.

Using a screwdriver in the notch on the piston boss, remove the retaining ring holding the piston pin.

Remove the second snap ring in the same way

Using a suitable drift, push the pin out of the piston and remove the piston from the connecting rod

Remove the bearings from the connecting rod

Remove the bearings from the connecting rod cap.

If the liners remain on the crankshaft, remove them from the shaft.