Disconnect the ground wire from the battery

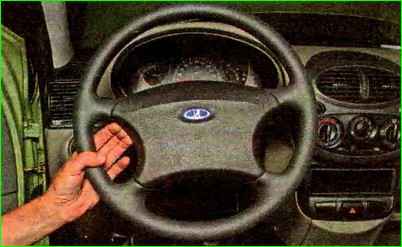

Use your fingers to press the horn switch cover

Move the pad away from the steering wheel.

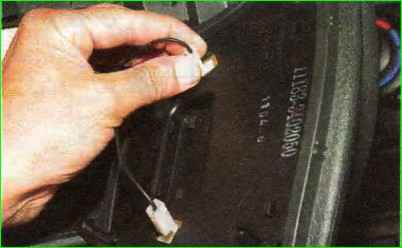

Disconnect the wire ends from the horn switch.

Use paint or a felt-tip pen to mark the position of the steering wheel relative to the shaft in order to correctly install the steering wheel.

Using a 24mm socket, unscrew the steering wheel fastening nut not completely (so as to avoid injury when removing the steering wheel)

Completely unscrew the steering wheel mounting nut.

By rocking, pull the steering wheel towards you and remove it from the shaft splines

Removing the steering wheel

Install the steering wheel in the reverse order, following the marks made during removal.

Removing a steering wheel equipped with an airbag

To complete the work, you will need a special puller to remove the airbag and a new steering wheel nut.

If you don’t have a puller, you can make one from an old slotted screwdriver with a blade width of 5-6 mm.

To do this, you need to cut a small groove in the middle of the blade.

Remove the “—” terminal of the battery (you need to wait at least 5 minutes before continuing work).

Set the front wheels of the car to the straight-line position.

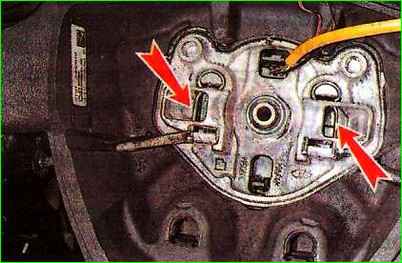

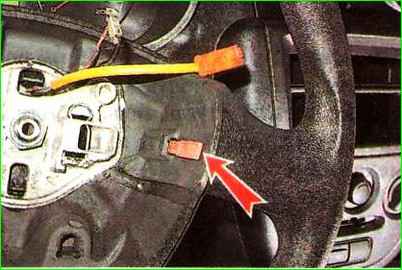

Through the holes in the steering wheel upholstery, using a homemade puller, first on one side and then on the other, pressing the outer antennae of the spring clips (for clarity, the airbag has been removed) we release the two airbag module holders

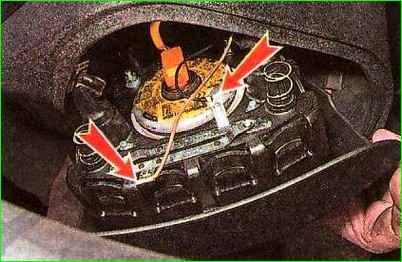

Moving the airbag module away from the steering wheel, disconnect the ends of the two wires.

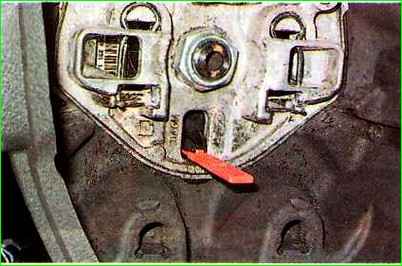

Use a slotted screwdriver with a thin blade to release the wire block retainer.

Disconnect the wire block from the airbag module danger

To avoid injury in case of inadvertent deployment of the airbag, place the removed module away from the workplace with the decorative trim facing up.

If it is necessary to install the steering wheel in the previous position, use any available method (marker, felt-tip pen, thin chisel) to make installation marks on the shaft and steering wheel.

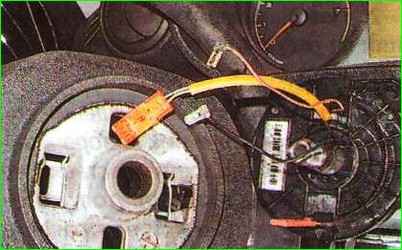

When removing the steering wheel, the moving part of the contact wheel is not automatically locked from rotation.

As a result, the central position of the moving part of the ring may be disrupted during assembly.

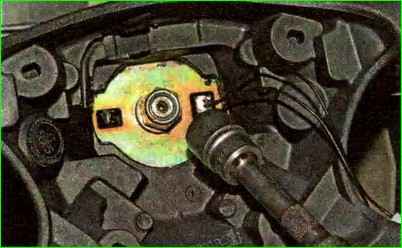

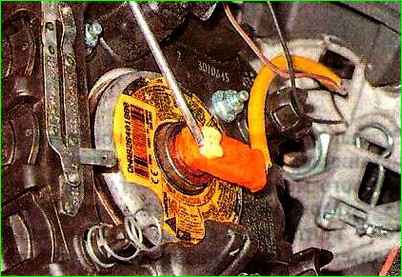

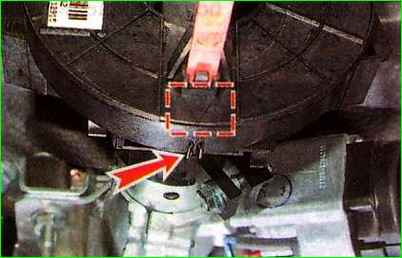

In this case, there is a high probability of damage to the contact ring when turning the steering wheel to one of the extreme positions; to fix the ring, the steering wheel is equipped with a special stopper

And there is a special hole on the slip ring.

By inserting a stopper into this hole, you can fix the moving part of the slip ring in a certain position.

When disassembling, it is necessary to lock the slip ring and do not remove the lock until the steering wheel is installed on the steering shaft.

Insert the stopper into a special hole to fix the slip ring

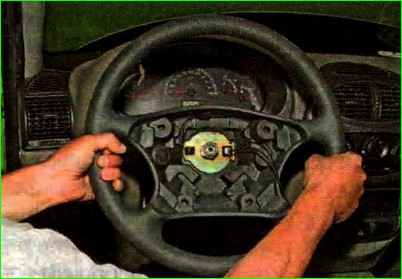

Using a 24mm socket wrench with an extension, unscrew the steering wheel mounting nut and leave the nut on several threads of the shaft thread.

By successive blows of your palms on the rim of the steering wheel on the right and left sides, we knock it off the shaft splines.

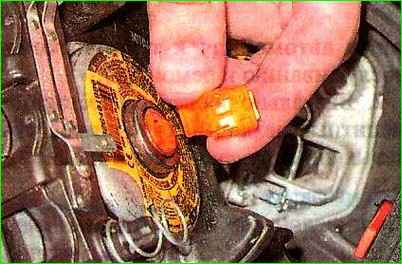

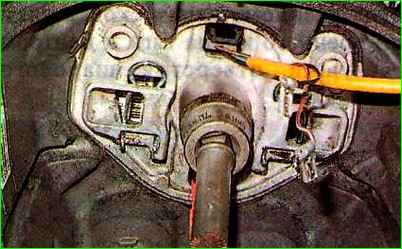

After unscrewing the nut, remove the steering wheel from the shaft, while pulling out the slip ring wires along with the pads from the hole in the steering wheel hub

Install the steering wheel in the reverse order, aligning the previously made marks and installing a new self-locking nut.

Steering wheel mounting nut with a torque of 32-51 Nm (3.2-5.2 kgf.m).

If you need to install the steering wheel in a new position (for example, if the spokes are tilted when the car is moving in a straight line), put the wheel on the shaft and secure it with a nut without tightening it completely.

After driving straight a few meters, make sure it is in the correct position.

If necessary, move the steering wheel to the required number of splines and tighten the nut.