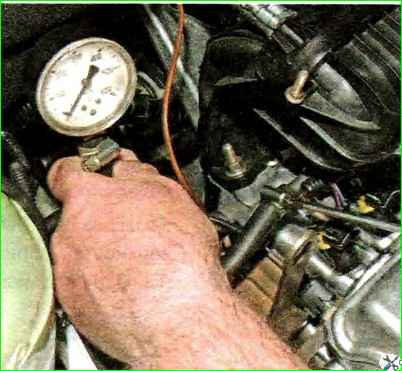

The pressure in the engine power supply system can be checked with a conventional pressure gauge (for example, from a tire pump)

We carry out the work on a cold engine.

Relieving pressure in the power system

We put an oil-resistant reinforced hose (with an internal diameter of 12 mm) onto the threaded fitting of the pressure gauge and secure it with a clamp.

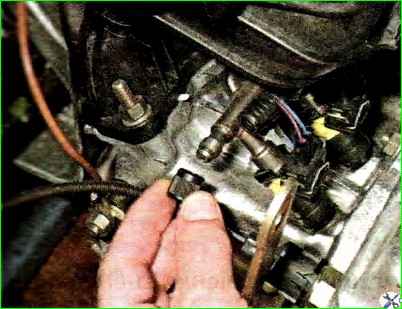

On the right side of the engine (in the direction of travel of the car), unscrew the plastic cap of the fitting on the fuel rail (for clarity, the plastic engine screen has been removed).

Use the wheel valve cap to unscrew the spool valve from the fuel rail fitting.

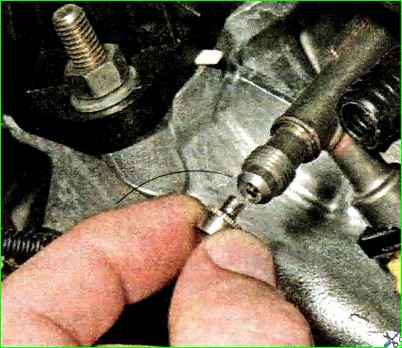

Remove the spool from the fuel rail

We put a manometer hose on the ramp fitting and secure it with a clamp

With the ignition off, for 3-5 minutes, using a wire, we supply “+” 12 V power from the battery to pin “11” of the diagnostic connector.

The electric fuel pump should turn on. Its operation can be checked by ear.

For 10 seconds, measure the fuel pressure, which should be 3.6-4.0 bar.

After turning off the pump, the pressure may decrease slightly and then stabilize for a while.

If the pressure in the system is more than 4.0 bar, the fuel pressure regulator is faulty.

Low pressure (below 3.6 bar) in the power system can be caused by a clogged fuel filter or fuel module strainer, as well as a malfunction of the electric fuel pump and fuel pressure regulator.

To check the fuel filter for contamination, you need to remove it, drain the remaining fuel from it and blow through a piece of hose (you can use your mouth).

The resistance to air passage when blowing should be insignificant.

Otherwise, we replace the fuel filter with a new one, which we recommend always keeping in stock.

We check the condition of the fuel module strainer after dismantling the module.

If the mesh filter is very dirty, clean and rinse it.

To check the serviceability of the fuel pressure regulator (at low pressure), connect a hose with a pressure gauge directly to the outlet fitting of the fuel module.

We supply power to the electric fuel pump as indicated above.

If the fuel pressure is 3.6 bar or higher, the regulator is releasing fuel pressure too quickly.

This regulator is faulty and must be replaced.

If the fuel pressure in the engine power supply system is low and continues to drop after the electric fuel pump is turned off, this may be caused by leaky fuel module connections, a pump malfunction, or leaking injectors.

To find the cause of the malfunction, turn on the electric fuel pump again for 10 seconds (supplying power to pin “11” of the diagnostic connector) and after turning it off, completely pinch the rubber hose supplying fuel to the fuel rail.

If the pressure stabilizes, then either the fuel module or the electric fuel pump is faulty. If the pressure continues to drop, one or more injectors are leaking.

A leaking injector can usually be identified by the dark color of its nozzle, which contains coked droplets of fuel.

Checking the tightness of the injectors is described in the article - “How to remove the fuel rail and check the injectors of Lada Kalina”