Maintenance of the rear axle consists of maintaining the oil level in the crankcase and timely replacing it, checking seals, timely detection and elimination of axial clearances in the final drive gears

Periodically clean the safety valve and tighten all fasteners.

If the oil in the crankcase is heavily contaminated or there are metal particles in it, then rinse the crankcase with kerosene before adding fresh oil.

To flush, pour 1–1.5 liters of kerosene into the crankcase; lift the wheels, start the engine and let it run for 1.0–1.5 minutes, then drain the kerosene and fill with fresh oil.

Axial play of the main gear drive gear is not allowed.

Check the clearance by rocking the drive gear by the driveshaft mounting flange.

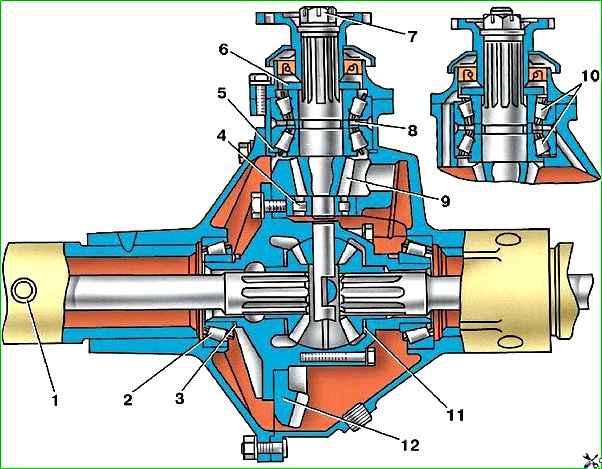

If an axial play of the drive gear of more than 0.05 mm appears during vehicle operation, tighten nut 7 (Fig. 1). Tightening torque – 167–206 Nm (17–21 kgf m).

If the gap does not disappear, make adjustments as indicated in the article “Assembling and adjusting rear axle components.”

Axial play of the main drive driven gear is not allowed. Check it by moving the gear through the oil filler hole.

To eliminate the gap, add sets of shims of equal thickness between the ends of the differential and bearings.

Do not add sets of shims of different thicknesses or install them on the same side of the driven gear, because this will lead to disruption of the engagement of worn-out gears and their rapid breakdown.