Combined wet sump lubrication system

The system includes an oil pump, an oil filter, an oil-water heat exchanger, an oil crankcase, an oil filler neck, an indicator tube and an oil level indicator.

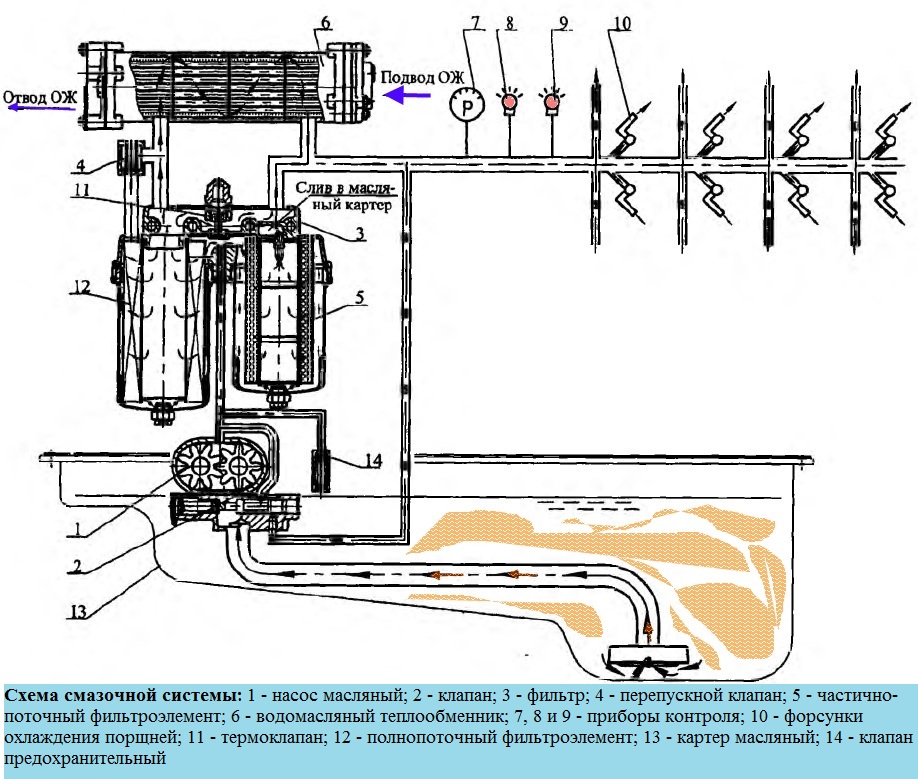

Scheme of the lubrication system is shown in fig. 1

From the crankcase 13, the oil pump 1 supplies oil to the oil filter 3 and through the water-oil heat exchanger 6 to the main line, then to the consumers.

The lubrication system also includes valve 2 of the system, which provides pressure in the main oil line 392-539kPa (4.0-5.5 kgf / cm2) at the rated speed of the engine crankshaft, bypass valve 4, adjusted to operate at a pressure drop across the filter of 147-216 kPa (1.5-2.2 kgf / cm2) and thermal valve 11 for turning on the oil-water heat exchanger.

When the oil temperature is below 95 °C, the valve is open and the main oil flow enters the engine bypassing the heat exchanger.

When the oil temperature is over 110°C, the thermal valve is closed and the entire oil flow passes through the heat exchanger, where it is cooled by water.

This ensures that the engine warms up quickly after starting and maintains the optimum temperature during operation.

Structurally, the thermal valve is located in the oil filter housing.

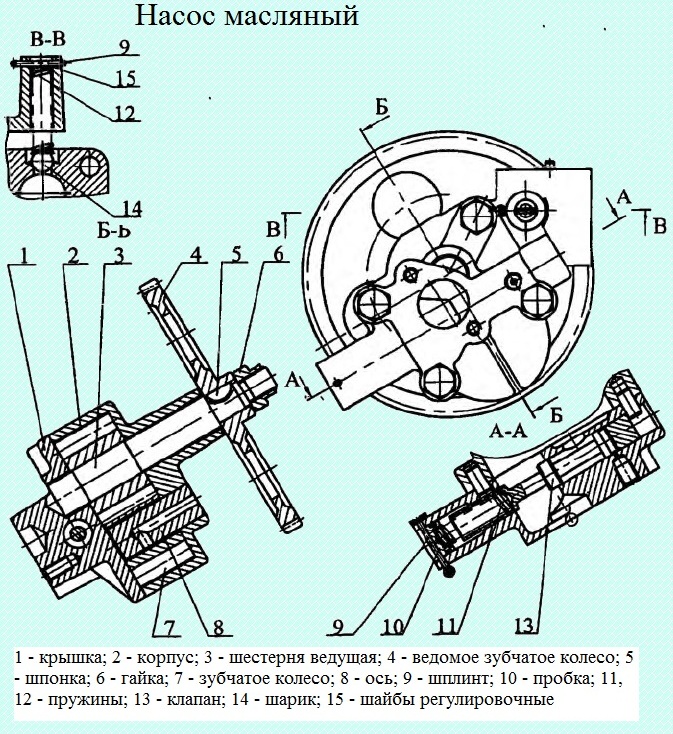

The oil pump (see picture) is mounted on the bottom plane of the cylinder block.

The drive gear is pressed onto the front end of the crankshaft and has 64 teeth, driven 52, that is, a gear ratio of 0.8125.

The gap in the engagement of the drive gears is regulated by gaskets installed between the mating surfaces of the pump and the block, which should be 0.15-0.35 mm, the tightening torque of the oil pump mounting bolts to the block should be 49-68.6 Nm (5-7 kgf.m).

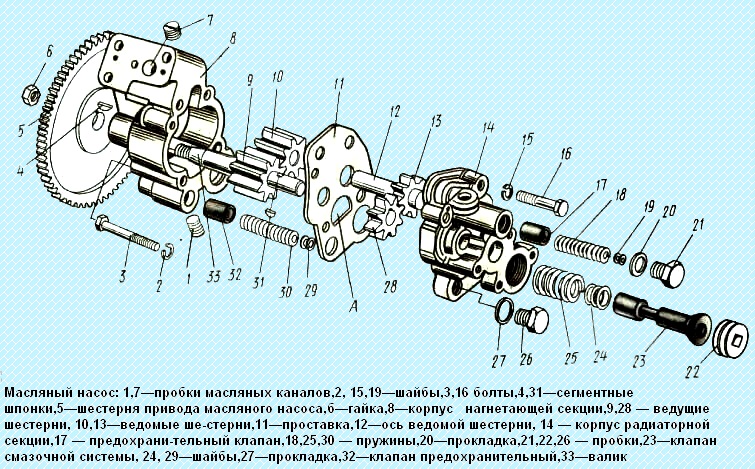

The oil pump is gear, one-section. Contains body 2, cover 1 and gears.

In the cover there is a lubrication system valve 13, with a spring 11. A safety valve is installed in the discharge channel, consisting of a ball, a spring and shims.

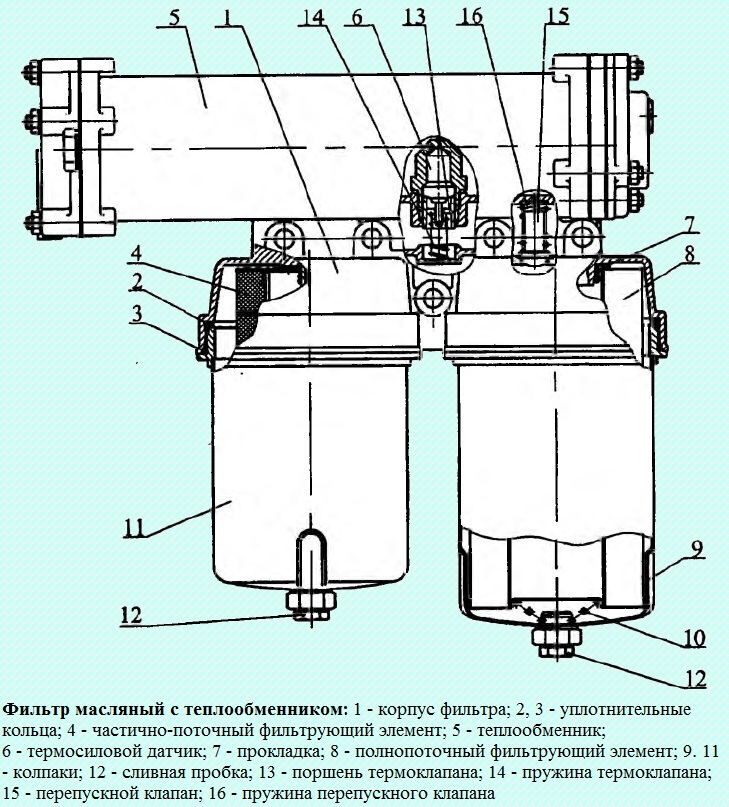

The oil filter (see figure) is fixed on the right side of the cylinder block and consists of a housing 1, two caps 9 and 11, in which full-flow 8 and partially-flow 4 filter elements are installed.

Threaded caps are screwed into the body. The sealing of the caps in the body is carried out by rings 2 and 3.

In the filter housing there is also a bypass valve 15 and a thermal valve for turning on the oil-water heat exchanger.

Combined oil cleaning in the filter.

The main flow of oil passes through the full-flow filter element 8 before it enters consumers, the fineness of oil purification from impurities is 40 microns.

Through the partially - flow filter element 4 passes 3-5 l / min. where impurities larger than 5 microns are removed.

Oil is drained from the partially treacle element into the crankcase. With this scheme, a high degree of oil purification from impurities is achieved.

The oil sump is stamped, attached to the cylinder block through a rubber cork gasket. The tightening torque of the crankcase mounting bolts is 8 - 17.8 Nm (0.8 - 1.8 kgf.m).

The thermal valve for turning on the oil-water heat exchanger consists of a spring-loaded piston 13 with a thermal force sensor 6.

At temperatures below 93 °C, piston 13 is in the upper position and the main part of the oil flow, bypassing the heat exchanger, enters the engine.

When the temperature of the oil reaches (95+2) °С, washing the thermal force sensor 6, the active mass in the cylinder begins to melt and, increasing in volume, moves the sensor rod and piston 13.

At the oil temperature (110+2) °C, the piston 13 separates the cavities in the filter before and after the heat exchanger and the entire oil flow goes through the heat exchanger.

When the oil temperature exceeds 115 °C, the temperature sensor is triggered and the signal light on the instrument panel lights up.

The oil-water heat exchanger (Fig. Oil filter with heat exchanger) is installed on the oil filter, shell-and-tube type, prefabricated.

Coolant passes through the tubes from the engine cooling system, outside - oil.

On the oil side, the pipes are finned in the form of cooling plates.

The oil flow in the heat exchanger crosses the water tubes four times, thereby achieving high oil cooling efficiency.

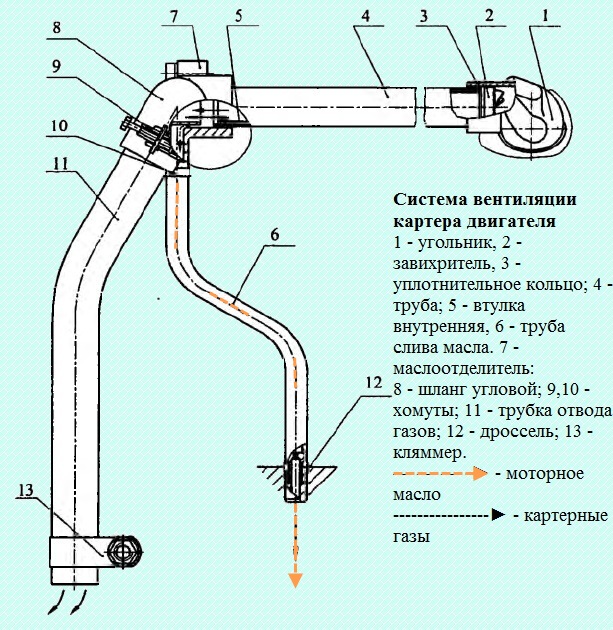

The crankcase ventilation system (see figure) is open, cyclone type.

The crankcase gases are discharged from the rod cavity of the second cylinder, through the elbow 1, in which the swirler 2 is installed.

When the engine is running, the crankcase gases, passing through the swirler 2, receive a helical motion.

Due to the action of centrifugal forces, the oil droplets contained in the gases are thrown to the wall of the pipe 4 and through the pipe 6 merge back into the crankcase.

Cleaned crankcase gases are removed to the atmosphere.

Possible malfunctions of the diesel lubrication system and solutions

Malfunction

- Cause of malfunction

Remedy

Increased oil consumption

- Prolonged operation of the engine at idle speed.

Unnecessarily do not work at idle speed of the engine.

- Oil leakage through connections in the turbocharger lubrication system.

Tighten connections, if necessary, replace gaskets and rubber sleeves.

- Wear of the valve-sleeve interface in the cylinder head, aging of the rubber cuff of the valve.

Check and replace worn parts.

- Clogged air cleaner or air intake hood.

Service the air cleaner and clean the mesh of the hood.

Reducing the oil pressure in the lubrication system

- Low oil level in the oil sump.

Check and, if necessary, add oil to the “B” mark.

- Malfunction of pressure control devices

Make sure the devices are working

- The use of oil of the wrong viscosity

Change the oil to the corresponding chemotological map.

- Dirty oil filter elements

Replace filter elements.

- Violation of the adjustment or jamming of the safety valve or the valve of the lubrication system

Check valves and eliminate jamming, if necessary adjust or replace defective parts.

- Clogged oil pump intake

Rinse the intake

- Coolant getting into oil

Check the tightness of the water cavity, the seal of the cylinder liners, the tightness of the water-oil heat exchanger, replace the defective parts.

- Oil leaks at the joints and oil lines of the lubrication system

Check the condition of technological plugs, plugs, tightness of fasteners at the joints, the condition of sealing rings and gaskets

- Violation of the oil pump

Remove the pump and check the operation on a special stand.

- Inadmissible increase in clearance in the bearings of the crankshaft and camshaft

Repair the engine.

Illumination of the emergency oil temperature indicator

- Malfunction of the emergency oil temperature sensor

Make sure the sensor is working, replace if necessary.

- Sticking of the thermal valve for turning on the heat exchanger, malfunction of the thermal force sensor

Check the operation of the thermal valve for turning on the heat exchanger, if necessary, eliminate jamming or replace the sensor.

- Clogged pipes or dirty cooling plates

Check the oil-water heat exchanger for clogged tubes and contamination of the cooling plates, flush or replace the heat exchanger if necessary.

Increasing the oil pressure in the lubrication system

- High oil viscosity

Change the oil to the corresponding chemotological map

- Violation of the tightness of the control signal line connecting the main oil line with the pump or its clogging

Check the oil supply pipe to the pump, the tightening of the fastening bolts, the presence of a hole in the cover

- Jamming or misadjustment of the lubrication system valve.

Check the valve and eliminate the jamming, if necessary, replace the defective parts.

Repair of oil system elements

For disassembly, assembly and inspection of the oil pump:

- drain the oil from the crankcase, unscrew the mounting bolts and remove the crankcase;

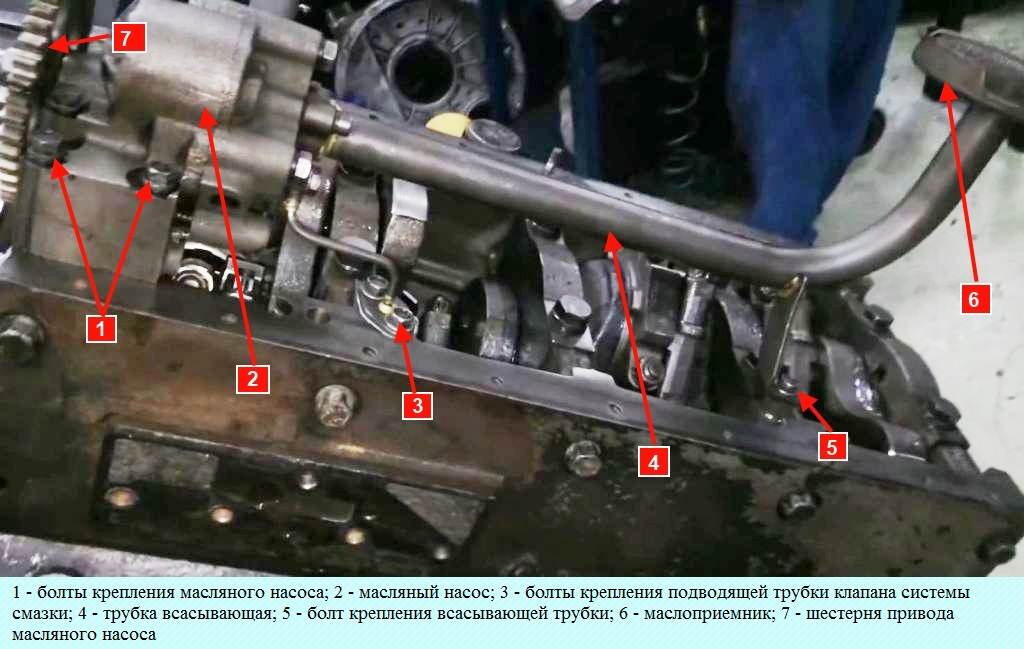

- — remove the suction tube 4 (Fig.) with the flange, bracket and cup assembly and the inlet tube of the lubrication system valve;

- — Turn out bolts of fastening of the oil pump 1, remove the pump;

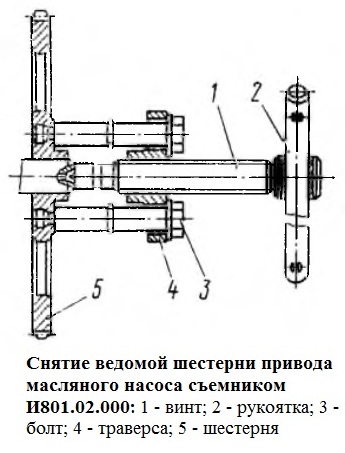

- remove the oil pump gear with a puller I80 1.02.000 (Fig.), to do this, screw the bolts 3 into gear 5 as far as they will go, screw 1 against the end of the shaft.

Rotating the handle, screw the screw into the traverse until the gear is completely removed;

- - Remove the bolts for fastening the delivery and radiator sections of the oil pump and disassemble it;

- - measure the radial and end clearances of the discharge and radiator sections, the gaps in the meshing of the gear teeth in the radiator and discharge sections, between the drive shaft and the hole in the housing, between the axle and the gear.

Replace worn parts if necessary;

- when assembling the pump, do not reuse the flap washers.

After assembling the pump, the roller should turn by hand smoothly, without jamming;

- test the pump on the stand using M10G2K or M10DM oil.

With a roller speed of 2800 - 60 min-1 and a suction vacuum of 12-15 kPa, the pump flow should be at least 130 l / min at an outlet pressure of 0.35 - 0.40 MPa ;

- adjust the actuation pressure of the lubrication system valve, which should be 0.40 - 0.45 MPa.

For regulation, it is allowed to use no more than 3 washers installed under the spring.

If there is a discrepancy between the pressure-start valve opening, replace the spring. Reuse of the cork cotter pin is not allowed.

Tightening torques for threaded connections, N.m (kgf.m)

- Oil pump mounting bolts 49.0 - 68.6 (5 - 7)

- Cover bolts 39.2 - 54.9 (4 - 5.6)

- Bolts for fastening the tube to the pump 19.6-24.5 (2-2.5)

- Oil filter caps 49.0-58.8 (5 - 6)

- Filter thermal valve plug 47.0 - 58.8 (4.8 - 6)

- Cap drain plugs 24.5-39.2 (2.5-4.0)

- Oil filter mounting bolts 88.2-112.6 (9.0-12.5)

- Nut for fastening the driven gear of the oil pump drive 98.1-117.6 (10-12)

Part dimensions and allowable wear, mm

- Gear diameter 55.44 - 55.47

- Permissible gear diameter 55.4

- Radial clearance between gear teeth and housing wall 0.130-0.206

- 0.25 allowable radial clearance

- Gear height 34.913 -34.975

- Permissible gear height 34,900

- Manhole depth 35.050-35.089

- End clearance 0.075-0.176

- 0.2 end clearance allowed

- Roll neck diameter 19.920 - 19.899

- Permissible neck diameter 19.85

- The diameter of the bushings in the housing for the neck of the roller is 19.98-19.959

- Permissible bushing diameter 20.10

- Axle diameter 19.987 - 20.000

- Permissible axle diameter 19.85

- Diameter of driven gear bushings 20.040-20.073

- Allowable bushing diameter 20.080

- Valve plug diameter 15.968-15.941

- Plunger diameter allowed 15.92

- Valve cover hole diameter 16,000-16,027

- Valve spring force compressed to size 44 mm, N 60-74

To disassemble, assemble and check the oil filter:

- - drain the coolant from the engine cooling system;

- - unscrew the drain plugs from the caps and drain the oil from the filter;

- - disconnect the coolant inlet and outlet pipes to the heat exchanger;

- - unscrew the five mounting bolts and remove the filter with the heat exchanger;

- - unscrew the nuts and disconnect the heat exchanger from the filter;

- - unscrew the caps from the body, wash the internal cavity with diesel fuel, check the integrity sealing rings, thrust springs, replace if damaged;

- - check the assembled filter for tightness with compressed air 490 kPa in water;

- - check the pressure at the beginning of the bypass valve opening, which should be 0.147-0.216 MPa;

- - check the operation of the thermal valve for turning on the heat exchanger.

At the oil temperature (50-70) °C, the flow through the valve must be at least 70 l/min at a pressure of 0.147 kPa and not more than 5 l/min at a temperature of 100-110 °C.

If necessary, replace the thermal force sensor TC 103-1306090-30.

To disassemble, assemble and check the operation of the oil-water heat exchanger:

- - install plugs on the oil supply flanges and pressurize the oil cavity with a pressure of 0.79-0.83 MPa in water, if a leak is found, remove the inlet and outlet manifolds of the heat exchanger and remove the core from the housing, replace the sealing rings or, if the tubes are damaged, the core .