General information about Kamaz vehicle maintenance

The scope of maintenance includes inspection and diagnostic, fastening, lubrication, adjustment, electrical and installation and dismantling work associated with checking and adjusting individual components and assemblies on special stands and equipment

If during maintenance there is doubt about the complete serviceability of a separate assembly unit, then check it with a special device or on a stand.

Maintenance of KamAZ vehicles (road trains) is divided into maintenance during the initial and main periods of operation.

Maintenance during the initial period of operation:

- - daily maintenance;

- - maintenance after the first 1000 km (service A);

- - maintenance after the first 4000 km (service B);

- - service 1 after the first 8000 km;

- - service 2 after the first 12,000 km.

Maintenance during the main period of operation:

Car maintenance frequency

- - daily maintenance;

- - service 1;

- - service 2;

- - seasonal maintenance (service C).

The main purpose of daily maintenance is general monitoring of the condition of units and systems that ensure traffic safety, and maintaining proper appearance.

During the initial period of operation, parts in the vehicle’s components are worn in, so when carrying out maintenance during this period, carry out preventive fastening and lubrication and cleaning work with special care.

Initial maintenance is carried out regardless of operating conditions.

During the main period of operation, maintenance work is carried out at intervals corresponding to the category of operating conditions

Frequency of vehicle maintenance depending on the characteristics of operating conditions:

Motor roads with asphalt concrete, cement concrete and similar surfaces outside the suburban area

Motor roads with asphalt concrete, cement concrete and similar surfaces in the suburban area, streets of small cities (with a population of up to 100 thousand inhabitants):

- - service 1: 4000 km;

- - service 2: 12000 km;

- - service C: 24,000 km.

Motor roads with asphalt concrete and similar surfaces in mountainous areas. Streets of big cities

Roads with crushed stone or gravel covering

Dirt profiled and logging roads

- - service 1: 3200 km;

- - service 2: 9600 km;

- - service C: 19200 km.

Roads with crushed stone or gravel surfaces in mountainous areas

Unprofiled roads and stubble. Quarries, pits and temporary access roads

- - service 1: 2400 km;

- - service 2: 7200 km;

- - service C: 14400 km.

Seasonal maintenance includes additional autumn work, which is performed once a year.

All types of maintenance are carried out within the time limits specified in the service book.

Lubrication

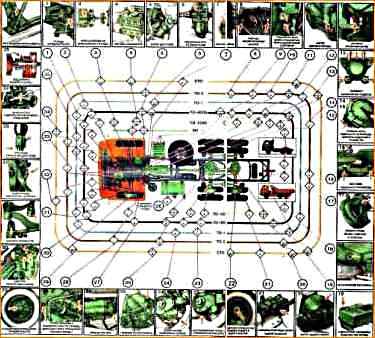

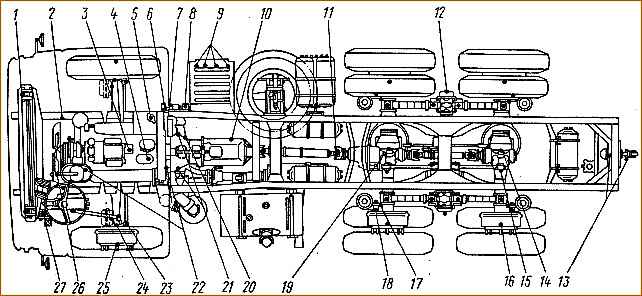

The name of the oils, quantity and frequency of lubrication are indicated in the chemical lubrication chart of the vehicle, and the location of assembly units and units that require periodic replenishment or oil replacement is shown in Figure 2.

Remember that the use of substitutes significantly reduces the durability of vehicle assembly units (for example, a power steering mechanism by three to four times) and is allowed only as a temporary measure.

When switching from one recommended type of oil to another, flush the gearbox with a mixture of 50% diesel fuel and 50% fresh oil intended for subsequent oil filling, cranking the engine for 5-10 minutes with the gearbox in neutral.

Chemical map of Kamaz vehicles

Diagram of lubrication points: 1 - axis of the front support of the cabin; 2 - front spring pins; 3 - fuel injection advance clutch; 4 - tank power steering pump; 5 - cooling system; 6 - engine crankcase; 7 - anti-freeze fuse; 8 - battery switch; 9 - battery terminals; 10 - gearbox housing; 11 - joints of cardan shafts; 12 - balancer shoes; 13 - stem of the hook of the towing device; 14 - rear axle housing; 15 - reaction rod hinges, 16 - hub bearings; 17 - adjusting levers of brake mechanisms; 18 - bushings for expansion fist shafts; 19 - intermediate axle housing; 20 - clutch release bearing; 21 - clutch release fork shaft bearing; 22 - supports for the front and intermediate rods of the remote control drive; 23 - steering rod joints; 24 - steering knuckle pins; 25 - front axle wheel hub bearings; 26 - divider control valve cable; 27 - hydraulic clutch release

- Car engine power system

Basic:

In summer: Diesel fuel L-02-40 GOST 305 (at air temperature 0 °C and above)

In winter: Diesel fuel 3-02 minus 35 GOST 305 (at air temperature minus 20 °C and above); Diesel fuel 3-02 minus 45 GOST 305 (at air temperature minus 30 °C and above); Diesel fuel A-02 GOST 305 (at air temperature minus 50 °C and above)

Duplicates:

In summer: Diesel fuel L-0540 GOST 305 (at air temperature 0 °C and above)

In winter: Diesel fuel 3-05 minus 35 GOST 305 (at air temperature minus 20 °C and above); Diesel fuel 3-05 minus 45 GOST 305 (at air temperature minus 30 °C and above); Diesel fuel A-05 GOST 305 (at air temperature minus 50 °C and above)

- Oil crankcase (engines: 7403.10, 740.11-240, 740.13-260, 740.0-260, 740.30-260) - cars with a 6x6 wheel arrangement, capacity 36 liters; - cars with 6x4, 8x4 wheel arrangement, - capacity – 30 liters

All-season: Motor oil Ufalyub HD Extra 15W-40 TU 0253-00211493112; LUKOIL-Super SAE 15W-40 CE/SG; LUKOIL-Super SAE 15W-40 CF- 4/SG LUKOIL-Super SAE 5W-40, CF- 4/SG, TU 0253-07500148636

In summer: Motor oil M-10-D (m) GOST 8581

In winter: Motor oil M-8-D (m) GOST 8581

Foreign oils - API CE, CF-4 SAE 15W-40 SAE 5W-40

During daily maintenance, check the oil level in the crankcase and top up if necessary

- For TO-5500 – change the oil;

- During maintenance-2 - change the oil

- The fuel injection advance clutch (if equipped) is lubricated with engine oil. Capacity 0.140 liters

For TO-1000 – bring the oil level to normal

During repairs - change the oil when checking and adjusting the injection pump on the stand

- Gearbox housing:

- KP-142(14) – 8.5 liters;

- KP-152(15) – 12 liters;

- KP-161 – 11 liters;

- ZF-9S109 – 8 liters

All-season: Oil TSp-15K GOST 23652 Oil TM3-18 KAMA TU 38 301-19-63 (at ambient temperature not lower than minus 30 “C)

All-season: Oil “Omskoil K” TU 38 301-19-93 (at ambient temperature not lower than minus 30 “C); A mixture of TSp-15K oil with 1518% diesel fuel grade “3” or “A” (at temperatures below minus 30 “C)

Foreign oils: API GL-3, APIGL-4 SAE 80W-90 SAE 85W-90

- For TO-1000 – bring the oil level to normal;

- For TO-5500 – change the oil;

- For maintenance-2 – bring the oil level to normal;

At 100,000 km. – Change oil

- Carter:

- - front axle – 5.8 liters;

- - middle axle – 7.0 liters;

- - rear axle – 7.0 liters

All-season: Oil TSp-15K GOST 23652 Oil TM3-18 KAMA TU 38 301-19-63 (at ambient temperature not lower than minus 30 “C)

All-season: Oil “Omskoil K” TU 38 301-19-93 (at ambient temperature not lower than minus 30 “C); A mixture of TSp-15K oil with 1518% diesel fuel grade “3” or “A” (at temperatures below minus 30 “C)

Foreign oils: API GL-3, APIGL-4 SAE 80W-90 SAE 85W-90

- For TO-1000 – bring the oil level to normal;

- For TO-5500 – change the oil;

- For maintenance-2 – bring the oil level to normal;

- With a mileage of 50,000 km - change the oil at least once a year

- Transfer case:

- - with power take-off – 5.4 liters;

- - without power take-off – 4.5 liters;

All-season: Oil TSp-15K GOST 23652 Oil TM3-18 KAMA TU 38 301-19-63 (at ambient temperature not lower than minus 30 “C)

All-season: Oil “Omskoil K” TU 38 301-19-93 (at ambient temperature not lower than minus 30 “C); A mixture of TSp-15K oil with 1518% diesel fuel grade “3” or “A” (at temperatures below minus 30 “C)

Foreign oils: API GL-3, APIGL-4 SAE 80W-90 SAE 85W-90

- For TO-1000 – bring the oil level to normal;

- For TO-5500 – change the masslo;

- For maintenance-2 – bring the oil level to normal;

- With a mileage of 50,000 km - change the oil at least once a year

- Balancer shoes, two lubrication points, 2.0 liter capacity

The oil used is the same as when servicing the gearbox

- For TO-1000 – bring the level to normal;

- For maintenance-2, service station - change the oil when adjusting the axial clearance

- Center differential housing:

The oil used is the same as when servicing the gearbox, capacity is 1.2 liters. At a service station, change the oil when disassembling and repairing the unit

- Front axle ball joint cavity - two lubrication points, capacity 6.0 liters.

A mixture of 50% TSp-15K oil GOST 23652 with 50% Litol-24 lubricant GOST 21150

Disassemble the hinge and replace the lubricant

- Upper king pin bearings - two 0.2 liter lubrication points

A mixture of 50% TSp-15K oil GOST 23652 with 50% Litol-24 lubricant GOST 21150

For TO-10000 and TO-2, lubricate through grease nipples

- Gear divider control valve cable - oil used in the gearbox, capacity 0.002 liters

During service maintenance, lubricate using an oil can

- Knuckle pins - four lubrication points

Lita lubricant TU 381011308, Litol-24 lubricant, foreign Shell lubricant: Aeroshell, Grease 6, 22, capacity 0.072 kg

For TO-1000, TO-5500, TO-1 - lubricate through a grease nipple, making no more than three strokes

- Clutch release bearing - one lubrication point, 0.015 kg. For TO-1000, TO-5500, TO-2 – lubricate through a grease nipple

- PGU - one lubrication point, 0.06 kg - lubricate during repair and assembly of the unit

- Clutch release fork shaft bushing - two lubrication points, the same lubrication, 0.015 kg. For TO-1000, TO-5500, TO-2 – lubricate through a grease nipple

- Front Cover Guide (Model 17 Clutch) - Single Lubrication Point

Lita lubricant TU 381011308, Litol-24 lubricant, foreign Shell lubricant: Aeroshell, Grease 6, 22, capacity 0.015 kg

For TO-1000, TO-5500, TO-2 - lubricate through the grease nipple, making no more than two strokes with the syringe

- Input shaft front bearing - single lubrication point, 0.015 kg. Lubrication is the same - lubricate when removing the gearbox

- Ball bearing of the gear shift lever* Lubrication is the same - 0.01 kg - lubricate when assembling and repairing the unit

- Gearbox control rod axis* - 0.008 kg - same lubrication - lubricate when assembling and repairing the unit

- Gearbox control rod ball joint* - 0.01 kg - same lubrication - lubricate when assembling and repairing the unit

- Tier thrust ball joints* - 0.02 kg - same lubrication - lubricate when assembling and repairing the unit

- Ball joints of the remote control drive of the gearbox* - 0.02 kg - lubricant is the same - lubricate when assembling and repairing the unit

- Range multiplier activation valve* - 0.02 kg - lubricant is the same - lubricate when assembling and repairing the unit

- Gear shift lock* - 0.005 kg - same lubrication - lubricate when assembling and repairing the unit

- Supports of remote drive transmission control rods* 0.05 kg - lubricant is the same - lubricate when assembling and repairing the unit

- Gearbox shift lever tip* - 0.03 kg - lubricant is the same - lubricate when assembling and repairing the unit

(* For gearbox 161 as part of a power unit with engine 740.20-260, 740.30-260)

- Gear divider control valve - one lubrication point - 0.01 kg - Tsiatim-221 lubricant or Lita TU 381011308 lubricant, foreign Shell lubricant: Aeroshell, Grease 6, 22 - lubricate when assembling and repairing the unit

- Gear divider activation valve - 0.02 kg - lubrication is the same - lubricate when assembling and repairing the unit

- Gear divider switching mechanism - two lubrication points - 0.02 kg - lubrication is the same - lubricate when assembling and repairing the unit

- Reducing valve for controlling the mechanism - 0.01 kg - lubrication is the same - lubricate when assembling and repairing the unit

- Gear divider control air distributor, one lubrication point. Grease Tsiatim-221 or grease Lita TU 381011308, foreign Shell grease: Aeroshell, Grease 6.22, Alvania Ep 2 - lubricate during assembly and repair of the unit

- The cavity of the speedometer sensor replacement gears is 0.015 kg - the lubricant is the same - lubricate when assembling and repairing the unit

- Radiator shutter control rod - one lubrication point. Lubricant Litol-24, Solidoly Zh, foreign lubricant Shell, Alvania Ep 2 - 0.03 kg - lubricate during assembly and repair of the unit

- Manual engine stop control rod - one lubrication point, 0.03 kg - lubrication is the same - lubricate when assembling and repairing the unit

- The ball pins of the rod ends of the injection pump lever drive are two lubrication points. Lubricant Litol-24 foreign lubricant Shell, Alvania Ep 2 - 0.015 kg - lubricant the same - lubricate when assembling and repairing the unit

- Telescopic fuel control pusher - one lubrication point. Lubrication is the same - add 0.005 kg lubricant

- Cooling system drain valve - Litol-24, Tsiatim-221 lubricant, foreign Shell lubricant: Aeroshell, Grease 6.22, Alvania Ep

- Spline connections of axle driveshafts. Lubrication is the same - When assembling and repairing, lubricate the splines and put grease in the spline connections

- Cardan shaft joints have two lubrication points. Lubricate at TO-1000, TO-2 during operation through grease nipples until fresh grease is squeezed out from under the edges of the seals

- Front axle wheel hub bearing two lubrication points, front, second axle (KAMAZ-6540) four lubrication points. Lubricant Litol-24, Tsiatim-221, foreign Shell lubricant: Aeroshell, Grease 6.22, Alvania Ep. With the hub removed, apply lubricant between the rollers and cages evenly throughout the entire bearing cavity

- The wheel hub bearing of the middle and rear axle has two lubrication points. The lubricant is the same, 0.8 kg each. With the hub removed, apply lubricant between the rollers and cages evenly throughout the entire bearing cavity

- Spare wheel holder (rubbing surfaces). Lubricant Litol-24, Solidoly Zh, foreign lubricant Shell, Alvania Ep 2 - 0.03 kg - lubricate during assembly and repair of the unit

- Tie rod joints - four lubrication points. The lubricant is the same - 0.150 kg. For TO-1000, TO-5500, TO-1 - lubricate through grease nipples until fresh grease is squeezed out

- Steering driveshaft joints – eight lubrication points. Lubricant Litol-24, Tsiatim-221, foreign Shell lubricant: Aeroshell, Grease 6.22, Alvania Ep - lubricate during repair and assembly of the unit

- Splines of the steering drive shaft. Lubricate when repairing and assembling the unit. The lubricant is the same 0.040 kg.

- Front spring pins - two lubrication points.

- Rear and front springs (leaves), for KamAZ-6540

- Adjusting levers for brake mechanisms, for KamAZ-6540

- Extension fist shaft bushings:

- - front bracket;

- - front bracket for KamAZ-6540

- Extension fist shaft bushings: - rear bracket. Lubricate through grease nipples until fresh grease is squeezed out

- Lubricate the brake pad roller and the roller axis with a thin layer when assembling and repairing the unit

- Seats of the brake pad axle - lubricate with a thin layer when assembling and repairing the unit

- Control cable for the right and left dampers of the heating system, the valve of the heating system - lubricate with a thin layer when assembling and repairing the unit

- Lubricate the axles of the front cab supports - for TO-1000, TO-5500, TO-1 - through a grease nipple until fresh grease is squeezed out

- Ground switch - lubricate when assembling and repairing the unit

- Rear cabin springs - two lubrication points. Graphite lubricant USS-A, foreign - Shell: Alvania HDX 2, Rhodina EP 2. Lubricate when disassembling and repairing the unit

- Driver's seat torsion bar plates - lubricate if necessary

- Torsion bar screw bearing - lubricate when repairing and disassembling the unit

- The roller axes and guides of the driver’s seat levers should be lubricated when repairing and disassembling the unit

- Running tracks of balls and rollers of the guide mechanisms for moving the driver's seat - lubricate if necessary

- Door opening limiter - lubricate if necessary

- Cabin lock - lubricate if necessary

- Cabin door hinge - 0.010 kg - Lubricate when assembling and repairing the unit

- Cab door window regulator. Grease Lita TU 381011308 or Tsiatim-201 GOST 6267, Grease Litol-24 GOST 21150, Shell: Aeroshell Grease 6, 22 0.020 kg. Lubricate when assembling and repairing the unit

- Cabin door lock - 0.020 kg - Lubricate if necessary

- Cabin door lock drive. Grease Lita TU 381011308, Grease Litol-24 GOST 21150 Shell: Aeroshell Grease 6, 22 Alvania EP 2 - 0.020 kg. Lubricate if necessary

- Outer cabin door handle - 0.005 kg - Lubricate if necessary

- Cabin heater control valve - 0.002 kg - Lubricate during repair and assembly of the unit

- Heating system drain valve. Grease Litol-24 GOST 21150, Grease Lita TU 38 1011308, Shell: Aeroshell Grease 6, - 22 0.002 kg - Lubricate during repair and assembly of the unit

- Battery terminals - Lubricant Litol-24 GOST 21150, Shell: Alvania EP 2 0.020 kg TO-2 - Lubricate with a thin layer

- Plug connections of electrical equipment - Grease Litol-24 GOST 21150, Grease VNI-INP-510 TU 38 101910, Shell: Alvania EP 2 Retinax EP 2 - 0.008 kg STO - Lubricate with a thin layer once a year

- Starter - Lubricant Lita TU 38 1011308, Lubricant Tsiatim-201 GOST 6267, Shell: Aeroshell Grease 6, 22 - 0.025 kg STO (once every 2 years) STO (once every 2 years) Lubricate the splined drive shaft.< /li>

- Water pump bearing. Lubricant Litol-24 GOST 21150, Lubricant Lita TU 381011308, Shell: Alvania EP 2 - 0.015 kg TO-2 TO-2 - Lubricate through the grease nipple

- Platform hinge axes 2 Lubricant Litol-24 GOST 21150, Solid oils Zh GOST 1033 or Solid oils S GOST 4366 Shell: Alvania EP 2 Retinax EP 2 - 0.036 kg TO-1. Lubricate through the grease nipple until fresh grease is squeezed out

- Hydraulic cylinder ball joints - 0.100 kg - Lubricate during repair and assembly of the unit

- Hydraulic cylinder mounting axles 0.100 kg - Lubricate during repair and assembly of the unit

- Platform mounting axes – 2 lubrication points. Lubricant Litol-24 GOST 21150, Solid oil GOST 1033, Shell: Alvania EP 2, Rhodina RL2 - 0.010 kg. Lubricate during repair and assembly of the unit

- Axles of fastening frame-stabilizer platform 2 - 0.010 kg - Lubricate during repair and assembly of the unit

- Tow hitch - 0.200 kg. Lubricate with a pressure oiler once a week

- Hitch matrix - 0.025 kg STO - Lubricate the nut, filling the matrix cover halfway with grease

- Fifth wheel – 0.170 kg TO-2 TO-1000 TO-1 - Lubricate through grease nipples

- Saddle support surface - 0.400 kg: TO-2 TO-1000 TO-1 - Lubricate the support plate with an even layer

- Towing device hook stem - 0.039 kg. TO-1000, TO-2 - Lubricate through the grease nipple

- Towing device nut - 0.025 kg. TO-1000 TO-2 - Lubricate through a grease nipple

Timber transport equipment

- Conic axis. Lubricant Litol-24 GOST 21150, Solid oil GOST 1033, Shell: Alvania EP 2, Rhodina RL2. TO-1000, TO-1 – lubricate through a grease nipple

- The axis of the bunk posts has two lubrication points. The lubrication is the same. Lubricate during assembly and if necessary

- Bottom plane of the turntable. Same

- Friction surfaces of the locking device mechanism. Same

- Tow frame pins. Same

- External surfaces of technological equipment not protected by paint coating (when stored in open areas). Gun lubricant (PVK) GOST 19537, Solid oil GOST 1033

Winch

- Winch gearbox. The oil used in the gearbox is 3,900 liters. Oil change once a year

- Winch guide rollers

- Winch cable

- Winch drum shaft bearing in the traverse. Grease Ligol-24 GOST 21150

- Winch driveshaft joints. Litol-24 lubricant

- Spline connection of cardan transmission

- Front suspension shock absorbers

- Cab shock absorbers. Shock-absorbing fluid AZh-12T GOST 23008

- Power steering - for KAMAZ-6540

- Hydraulic lift of cab and spare wheel

- Hydraulic system of the platform lifting mechanism: - KAMAZ-65111 - KAMAZ-65115 - KAMAZ-6540. In summer: Industrial I-20A GOST 20799 In winter: Industrial I-12A GOST 20799

- Hydraulic clutch release. Brake fluid

- Engine cooling system 740.20-260, 740.30-260 - with heater 15.8106; - with PZD-30; - with PZD-12B

- Engine cooling system 7403.10, 740.11-240, 740.13-260 – 33.5 liters – For daily maintenance, bring the level to normal.

- - with heater 15.8106 – 38 liters - Change the fluid once a year. The period for changing the Lena coolant is once every two years

- - with PZD-30; - with PZD-12B - Change the fluid once a year. The period for changing the Lena coolant is once every two years

Fastening work

The list of maintenance operations includes fastening work, the implementation of which is mandatory.

To control the performance of fastening work, the article - Tightening torques for KamAZ fasteners provides a table of tightening torques threaded connections tightened during maintenance.

Features of repair work

Routine vehicle repair consists of eliminating any malfunctions and damage that are detected during operation or maintenance through repair operations associated with partial or complete disassembly of units, assembly units or their replacement, as well as the replacement of individual parts (except for basic ones).

The basic part of the unit is the most complex and expensive part (body, base, frame, block, etc.), to which all other parts are attached.

Before disassembling the unit (engine) or any assembly unit located on it, check the general condition of the unit (engine) using diagnostic equipment and collect as much data about it as possible.

This will help determine the cause of the problem.

For a faster and more thorough inspection, clean the unit (engine) from dirt and wash it before inspection.

Remove, transport and install the unit (engine) using lifting vehicles equipped with devices that guarantee complete safety of work.

When performing repair operations, be guided by the following general principles

Disassemble and assemble parts of any assembly unit or unit on a special stand or workbench, using special tools skill and equipment

Assemble all assembly units and assemblies in the reverse order of disassembly. Therefore, when disassembling, place the parts in a certain order.

Disassemble parts connected by welding, riveting or fixed fits only in cases where this is caused by repair conditions.

Unscrew the studs only when necessary under the conditions of disassembling the unit or assembly unit, when replacing the stud and part.

Before tightening the cylinder head bolts (if they were removed), remove oil or water from the threaded holes of the block.

Do not depersonalize pairs of parts that are installed on the engine only as a complete set:

- - main bearing caps with a block, connecting rods with connecting rod caps, plunger pairs of a high-pressure fuel pump, a piston with a cylinder of a manual fuel priming pump, a rod with a rod bushing of a low-pressure fuel pump;

- - driven and drive gears, main transmission of drive axle gearboxes.

Carefully separate the gaskets from the contact surfaces using a screwdriver; press out parts only with the help of tools, or if they are not available, use special drifts or light blows of a copper (wooden) hammer.

To check the technical condition of all parts after disassembly, clean them from dust, scale, carbon deposits, varnish deposits, rust, rinse and dry. Do not wash parts made of aluminum and zinc alloys in alkaline solutions.

Inspection of parts, start with an external inspection; to identify defects on critical parts, use magnifying glasses or a magnetic flaw detector. Demagnetize parts that have been tested using a magnetic flaw detector.

When inspecting, discard:

- - parts that have significant scuffing, chipping or chipping, or traces of burning;

- - parts with cracks on working surfaces and in places that experience heavy loads during operation (for example, cracks on crankshafts and connecting rods are unacceptable);

- - fasteners with thread damage of more than two threads;

- - bolts and nuts with worn edges, as well as screws with clogged or torn head slots;

- - cotter wire and lock washers with folding edges;

- - rubber parts that have lost elasticity;

- - hoses with cracks and delaminations;

- - pipelines with dents that reduce their cross-section, or with cracks at the flared ends;

- - crumpled brass couplings;

- - metal panels and tail parts that have dents, cracks and holes on the surfaces;

- - fuel tanks with dents, leaks, or damage to the coating or paint.

Before assembly, prepare all parts as follows:

- - clean the nicks and burrs on the mating surfaces of the parts;

- - restore damaged threads within acceptable limits;

- - weld cracks or cavities in unloaded areas of parts (for example, in the walls of water jackets and exhaust gas pipelines); after welding, clean the seams to give the part the proper appearance;

- - the parting planes in which the warping slightly exceeds the permissible level should be corrected by scraping;

- - check the water and oil cavities of parts and assemblies, as well as high and low pressure fuel lines for leaks;

- - remove the anti-corrosion coating used when storing parts;

- - wash the parts and assemblies of the high-pressure fuel pump, hand pump and injectors with clean summer diesel fuel, precision parts (plunger pairs, discharge valves and nozzles) with gasoline.

After washing, blow off the parts with compressed air.

Do not wipe fuel equipment parts with cleaning material.

Before assembly, lubricate sealing gaskets, threads in plug holes and threads in through holes with sealing non-drying paste, and impregnate felt seals with grease.

Ready for assembly means that all assembly units subject to restoration have been restored or replaced with new ones and are ready for assembly.

During assembly work, inspect each mechanism and make sure that nothing was missed during restoration.

Assemblycarry out under conditions that guarantee the cleanliness of the parts.

When tightening connections sealed with rubber gaskets, do not use too much force, otherwise the gaskets will be destroyed.

Tighten the threaded connections during assembly, ensuring the torques recommended in Tightening torques for KamAZ fasteners

When pressing rolling bearings, the tool must rest against the ring being pressed.

When installing oil seals and cuffs, use mandrels.

After repair of assembly units and replacing them on the vehicle, perform a run-in to ensure that all mechanisms and systems are in good working order and that they interact correctly.