Turbochargers for diesel engines KAMAZ 740.11-240, 740.13-260, 740.14-300

The gas turbine pressurization system, due to the use of part of the energy of the exhaust gases, provides the supply of pre-compressed air to the engine cylinders

Supercharging allows you to increase the density of the air entering the cylinders, burn more fuel in the same working volume and, as a result, increase the liter engine power.

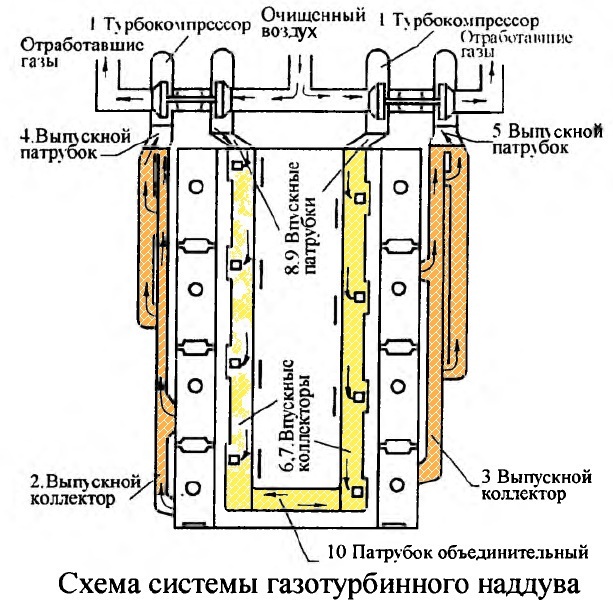

The gas turbine supercharging system of the engine consists of two interchangeable turbochargers, exhaust and intake manifolds and pipes (see picture).

Turbochargers are mounted on the exhaust pipes, one for each bank of cylinders.

Exhaust manifolds and pipes are made of ductile iron VCh50.

The sealing of gas joints between the mounting flanges of the turbine of turbochargers, exhaust pipes and manifolds is carried out with gaskets made of heat-resistant steel.

Gaskets are single-use parts and must be replaced when the system is overhauled.

The gas joint between the exhaust manifold and the cylinder head is sealed with a gasket made of asbestos sheet, edged with metal clad tape

The exhaust manifolds are made of one piece, bolted to the cylinder heads and secured with lock washers.

A special spherical washer is installed under the bolt head to compensate for the angular displacements of the exhaust manifold mounting bolt head that occur during heating.

The intake manifolds and pipes are made of cast aluminum alloy AK9ch and are interconnected with bolts. Joints between collectors and branch pipes are sealed with paronite gaskets.

To equalize the pressure between the two cylinder banks, the intake manifolds are connected by a union pipe.

The engine turbocharging system must be sealed.

If the tightness of the exhaust tract is violated, the rotational speed of the turbocharger rotor decreases, and therefore the amount of air injected into the cylinders decreases, which leads to an increase in the heat stress of parts, a decrease in engine power and life.

Leakage of the intake tract also leads to the above disadvantages and "dusty" wear of the cylinder-piston group, therefore, premature engine failure.

The turbocharger bearings are lubricated from the engine lubrication system through fluoroplastic tubes with a metal braid.

Oil from the turbochargers is drained through steel pipes into the crankcase. The drain pipes are interconnected by a rubber sleeve, which is pulled together with clamps.

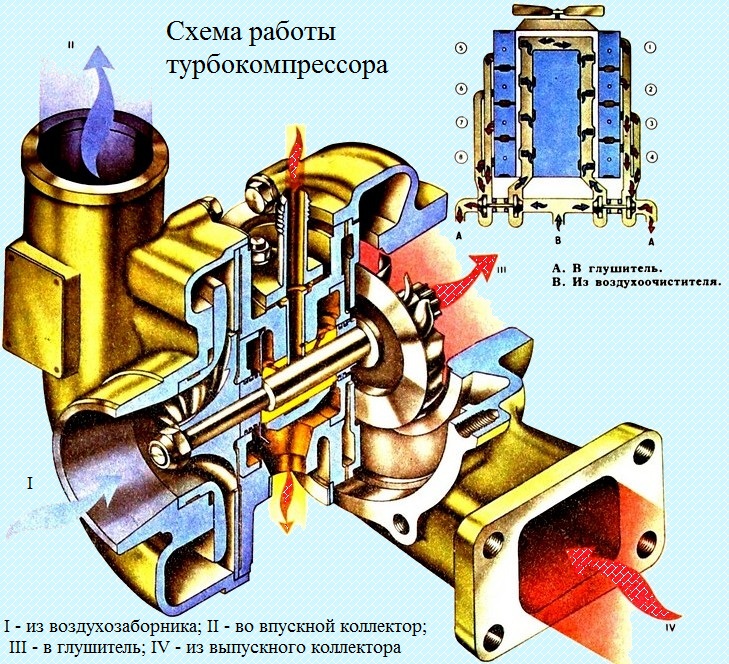

The air in the centrifugal compressor comes from the air cleaner, is compressed and supplied under pressure to the engine inlet.

The outlet pipe of the compressor and the inlet pipe of the collector are connected to each other by a heat-resistant rubber sleeve, which is pulled together with clamps.

The engines are equipped with a turbocharger TKR7N-1, TKR7S-9 (Fig. Turbocharger TKR 7C, Turbocharger TKR 7N) or its foreign analogue S2B/7624TAE/1.00 D9 from Schwitzer.

Turbochargers TKR7S-9 and TKR7N-1 are modifications of the basic models of turbochargers TKR7S and TKR7N, respectively.

The text and figures contain descriptions and images of basic models that are common to all modifications of the TKR.

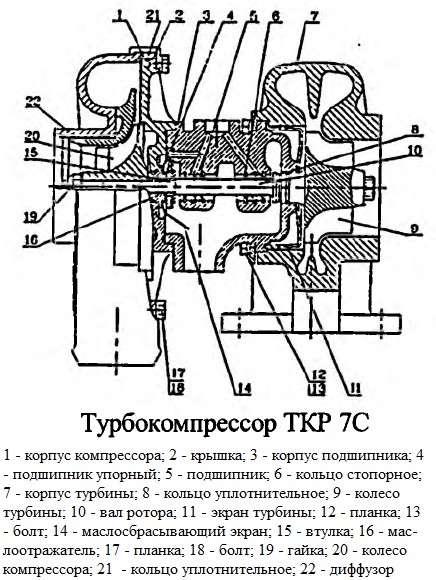

The TKR7S-9 turbocharger consists of a centripetal turbine and a centrifugal compressor connected to each other by a bearing assembly.

The turbine with a two-way casing 7 made of high-strength cast iron VCh40 converts the energy of the exhaust gases into the kinetic energy of the rotation of the turbocharger rotor, which is then converted into air compression work in the compressor stage.

The rotor of the TKR7S turbocharger consists of a turbine wheel 9 with a shaft 10, a compressor wheel 20, an oil deflector 16 and a bushing 15, fixed to the shaft with a nut 19.

The turbine wheel is cast from a heat-resistant investment alloy and welded to a steel shaft by friction.

The compressor wheel with backward-curved blades is made of aluminum alloy and, after machining, is dynamically balanced to a value of 0.4 g.mm.

The bearing journals of the rotor shaft are hardened THF to a depth of 1-1.5 mm to a hardness of 52-57 HRC3.

After machining, the rotor is dynamically balanced to a value of 0.5 g.mm.

The bushing, oil deflector, compressor wheel are mounted on the rotor shaft and tightened with a nut with a torque of 7.8-9.8 Nm (0.8-1 kgf.m). After assembly, the rotor is not additionally balanced, only the radial runout of the shaft pins is checked.

When the value of the radial runout is not more than 0.03 mm, marks are applied to the parts of the rotor in the same plane and the rotor is allowed to assemble the turbocharger.

When installing the rotor on the bearing housing, it is necessary to align the marks on the parts of the rotor.

The rotor rotates in bearings 5, which are floating rotating bushings.

Axial movement of the rotor is limited by thrust bearing 4, pinched between bearing housing 3 and cover 2. Bearings are made of bronze BrO10S10.

The turbocharger bearing housing, in order to reduce heat transfer from the turbine to the compressor, is made of a VCh50 cast iron housing and an aluminum alloy cover.

To reduce heat transfer, a screen 11 made of heat-resistant steel is installed between the turbine housing and the bearing housing.

In the bearing housing, an oil spill screen 14 is installed, which, together with elastic split rings 8, prevents oil leakage from the housing cavity.

To eliminate air leaks, a rubber sealing ring 21 is installed in the connection "compressor housing - bearing housing".

Turbine and compressor housings are attached to the bearing housing using bolts 12, 17 and strips 13, 18. This design allows you to install them at any angle to each other, which in turn facilitates the installation of the TKR on the engine.

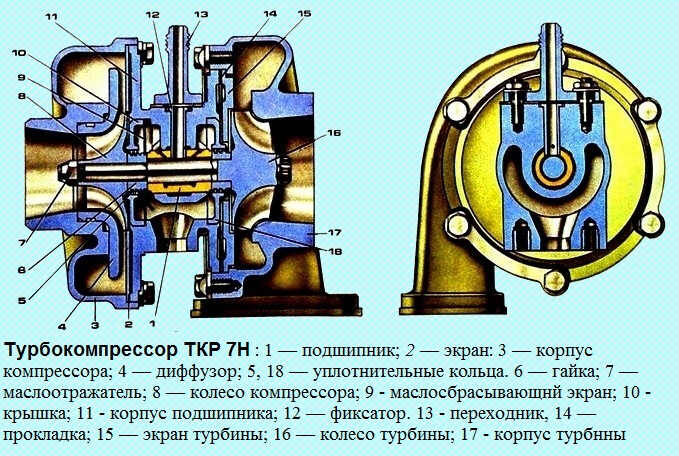

Turbocharger TKR7N

Unlike the TKR7S turbocharger, the design of the TKR7N turbocharger uses an isobaric single-thread turbine housing and a bronze oscillating mono-bushing as a bearing.

The turbocharger rotor consists of a turbine wheel with a shaft 16, a compressor wheel 8 and an oil deflector 7, fixed to the shaft with a nut 6.

The rotor rotates in bearing 1, which is kept from axial and radial movements by retainer 12, which, with adapter 13, is also an oil supply channel.

In the bearing housing 11, steel covers 10 and an oil-removing screen 9 are installed, which, together with elastic split rings 5, prevents oil from leaking from the cavity of the bearing housing.

To reduce the heat transfer from the turbine housing to the bearing housing, a cast-iron screen 15 and two steel gaskets 14 or a cast-iron shield 15 and an edged asbestos steel gasket 14 are installed between them.

Due to the fact that the turbocharger rotor is balanced with high precision, complete disassembly and maintenance of the unit must be carried out at specialized enterprises with the necessary equipment, tools and instruments.

The TKR 7N-1 or TKR 7S-9 turbocharger is installed on the 740.11-240 engine

The 740.13-260 and 740.14-300 engines are fitted with an S2B/7624TAE/1.00 D9 turbocharger

Technical characteristics of the turbocharger TKR7S-9

Range of air supply through the compressor, kg/sec: 0.05-0.2

Boost pressure (excessive) at rated engine power, kPa (kgf/cm2), not less than: 80 (0.8)

Rotor speed at rated engine power, rpm: 90000-100000

Gas temperature at the turbine inlet, K (°С)

- - allowable within 1 hour: 1023 (750)

- - allowed without time limit: 973 (700)

Pressure (excess) of lubricating oil at the inlet to the turbocharger, at an oil temperature of 80-95 °C, kPa (kgf/cm2)

- - at rated engine speed: 294-442 (3.0-4.5)

- - at minimum engine speed, not less than: 98 (1.0)

Technical characteristics of the turbocharger TKR7N-1

Range of air supply through the compressor, kg/sec: 0.05-0.18

Boost pressure (excessive) at rated engine power, kPa (kgf/cm2), not less than: 60 (0.6)

Rotor speed at rated engine power, rpm: 80000-90000

Gas temperature at the turbine inlet, K (°С)

- - allowable within 1 hour: 973 (700)

- - allowed without time limit: 923 (650)

Pressure (excess) of lubricating oil at the inlet to the turbocharger, at an oil temperature of 80-95 °C, kPa (kgf/cm2)

- - at rated engine speed: 294-442 (3.0-4.5)

- - at minimum engine speed, not less than: 98 (1.0)

Turbo specifications compressor S2B/7624T AE/1.00 D9

The range of air supply through the compressor, kg / s: 0.05-0.22

Boost pressure (excessive) at rated engine power, kPa (kgf/cm2), not less than: 110(1.1)

Rotor speed at rated engine power, rpm: 90000-100000

Gas temperature at the turbine inlet, K (°С)

- - allowable within 1 hour: 1023 (750)

- - allowed without time limit: 973 (700)

Pressure (excess) of lubricating oil at the inlet to the turbocharger, at an oil temperature of 80-95 °C, kPa (kgf/cm2)

- - at rated engine speed: 294-442 (3.0-4.5)

- - at minimum engine speed, not less than: 98 (1.0)

Recommended turbo engine operation

In order to avoid oil suction from turbochargers and getting it into the engine cylinders, on the flow parts of the compressor and turbine, it is not recommended to run the engine for more than 10 minutes at idle with a crankshaft speed of less than 700 min-1 .

This leads to coking of the piston rings, contamination of the flow path of the compressor and carbon formation on the flow path of the turbine.

When the engine is forced to run at idle (warming up, pumping air into the brake system cylinders, etc.), it is necessary to maintain the crankshaft speed of at least 1000-1200 min-1

Before stopping the engine after it has been running under load, it is necessary to set the idle mode for at least 3 minutes to avoid overheating of the turbocharger bearing and rotor coking.

It is forbidden to abruptly stop the engine after running under load.

Loss of power, smoke, high fuel consumption, engine overheating, high exhaust temperature, turbocharger oil leaks are symptoms of problems with turbocharging systems.

However, all this is often incorrectly attributed to a malfunction of the turbocharger, as defects in other parts of the engine lead to similar symptoms.

Since the turbocharger is a self-tuning engine unit, only mechanical failures or blockage of air and gas channels due to dirt and foreign objects impair its performance.

Before stopping the engine after it has been running under load, it is necessary to set the idle mode for at least 3 minutes to avoid overheating of the turbocharger bearing and rotor coking.

It is forbidden to abruptly stop the engine after running under load.

Turbocharger repair

If there is a leak in the connection between the turbine mounting flange and the manifold outlet, replace the steel gasket.

If extraneous noises appear, as well as increased smoke and a decrease in engine power related to the technical condition of the turbocharger, disconnect the exhaust pipe of the muffler from the turbocharger and check the ease of rotation of the rotor.

Remove the turbocharger if the rotor spins hard, jams, or rubs against the body parts.

Remove the turbocharger in the following order:

- - remove the air cleaner (when removing the left TKR), connecting pipes, tee;

- - disconnect the oil supply pipe to the TKR;

- - loosen the clamps fastening the connecting pipes of the compressor housing;

- - unlock and unscrew the exhaust manifold bolts, move the exhaust manifold back, disconnect the oil drain line, remove the exhaust manifold from the TCR assembly.

Note. For ease of subsequent installation, before disassembling the TKR, put pairing marks with the bearing housing on the turbine and compressor housings;

- - unscrew the six turbine mounting bolts and remove the compressor housing together with the bearing housing;

- - unscrew the eight bolts securing the compressor housing and remove it;

- - wash the compressor housing and screen in diesel fuel, remove deposits;

- - wash the bearing housing from the compressor side and remove deposits from the surfaces of the blades and housing.

Attention! In order to avoid damage to the surfaces of the blades and imbalance of the rotor, do not use metal objects to remove deposits and correct bent blades;

- check the integrity of the wheel blades and the absence of curvature on them. If there are damaged blades, replace the turbocharger.

Attention! Due to the fact that the turbocharger rotor is balanced with high precision during assembly, disassembly of the TKR rotor is not allowed.

Complete disassembly of the turbocharger is carried out at specialized enterprisesyah, having the necessary equipment and instruments;

- - assemble the turbocharger in reverse order. Install the compressor and turbine housings relative to the bearing housing according to the marks;

- - tighten the bolts of the compressor housing with a torque of 4.9-7.8 N.m (0.5-0.8 kgf.m), the bolts of the turbine housing with a torque of 23.5-29.4 N .m (2.4-3.0 kgf.m);

- - check the ease of rotation of the rotor and the absence of touching it on the body parts at its extreme axial and radial positions;

- - install the exhaust manifold, tighten the mounting bolts with a torque of 43.1-54.9 N.m (4.4-5.6 kgf-m), lock the bolts.

Possible turbocharging problems and solutions

Fault

- cause of failure

Troubleshooting

Engine power reduction, black smoke

- dirty air filter

Clean or replace the air filter

- blockage of the air supply to the TKR compressor

Remove clutter or replace defective parts

- a leak in the air supply line to the TKR compressor

Tighten clamp bolts, replace sleeves if necessary

- a leak in the air outlet route from the TKR compressor to the intake system

Tighten the bolts of the clamps, if necessary, replace the sleeves and gaskets

Blue smoke

- coking of the turbine rotor, sealing unit TKR

Repair in a specialized workshop or replacement of TKR

- poor crankcase ventilation

Remove resistance, replace defective parts if necessary