B10 fuel pump diaphragm, sealed, with three outlet and three inlet valves and a lever for manual fuel pumping

The pump is mounted on the left at the top of the engine and is driven by a camshaft eccentric using a rod.

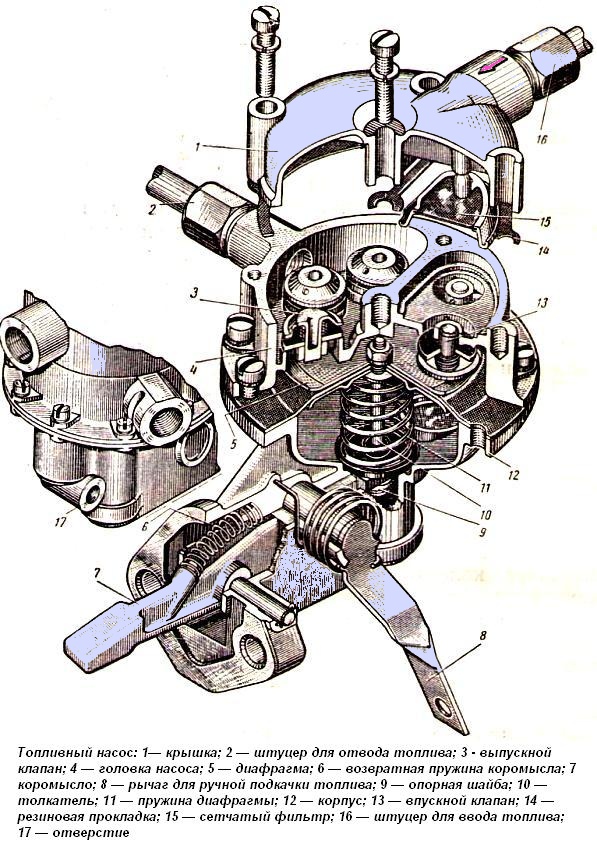

The pump consists of three main parts (Fig. 1): cover 1, head 4 and housing 12, die-cast from zinc alloy.

The rocker arm 7 with a return spring 6 and lever 8 for manual fuel pumping are assembled in the body.

A diaphragm 5 is fixed between the body and the head of the fuel pump, which is assembled on a pusher 10 with two plates.

The rocker acts on the pusher through the textolite support washer 9.

A return spring 11 is installed under the diaphragm.

The pump head has three inlet valves 13 and three outlet valves 3.

When the diaphragm moves down, the fuel from the tank passes through the tube through the strainer 15 to the intake valves.

When the diaphragm moves up, fuel is pumped through exhaust valves 3 into the head cavity, from where it is sent to the fine filter and then to the carburetor:

Depending on the fuel consumption, the amount supplied by the pump also changes.

A change in flow causes the fuel level in the float chamber to fluctuate and therefore changes the carburetor needle valve shut-off force; therefore, a back pressure is created in the fuel line connecting the pump to the carburetor, which is the greater, the less the needle valve is open, i.e. the lower the fuel consumption.

During back pressure, the diaphragm moves up according to the fuel flow at the moment.

Pump capacity 180 l/h (not less) at 2600-2800 rpm of the engine crankshaft. The maximum pressure at zero flow is not more than 225 mm Hg. st.

During operation, check the tightness of the pump daily and, if necessary, eliminate fuel leakage.

In case of insufficient fuel supply, it is necessary to check the condition of the diaphragm, observing whether there is any leakage through the control hole 17. In case of damage to the diaphragm, fuel will flow out of the hole.

Do not unnecessarily disassemble the fuel pump to avoid fuel leakage between the connector planes of the cover, head and housing.

When disassembling the pump, you need to remove the mesh and wash it in clean gasoline.

Disassemble and assemble the pump carefully so as not to damage the diaphragm and gasket.

When replacing the diaphragm, in order not to accidentally damage the sheet of rubberized diaphragm fabric, it is necessary to carefully tighten the pusher nut.

During the assembly of the diaphragm, it is necessary to ensure that dust particles and sawdust do not get between the plates and the diaphragm; metal chips, etc., as this leads to rapid wear of the diaphragm.

When assembling the fuel pump head with the housing, the connecting screws should be tightened with the diaphragm pressed to the lower position with the manual priming lever.