Before you doubt the quality of the turbocharger, you need to make sure that the engine and other units are in good condition

Each supercharged engine has a specific noise level. Therefore, many faults can be detected by changing the normal noise.

If the noise gets louder, the problem could be an air leak (between the turbocharger and the intake manifold) or exhaust gases, or a defect in the rotating shaft.

The intermittent noise may be due to a clogged turbocharger or using the engine too low in relation to the load.

The appearance of vibrations may indicate damage to the rotating shaft.

A sharp decrease in the noise level, accompanied by the appearance of black or gray smoke on the exhaust, indicates a complete failure of the turbocharger.

In all such cases, stop the engine immediately to prevent further damage to the engine or turbocharger.

Control on the car

Engine idling

Check the tightness of the air ducts between the air filter and the turbocharger by spraying the Startpilot fluid. In the case of leaks, an increase in engine speed is usually observed.

Engine at: 1200 rpm

Check the tightness between the turbocharger and the engine using a leak detector.

Check for exhaust leaks (use exhaust retarder), replace seals if necessary.

An exhaust gas leak can be detected by a discoloration at the leak.

Lack of engine power:

- - clogged air filter;

- - the charge air cooler is faulty (pipe clogging);

- - clogged or pinched air inlet pipes (between the air filter and the turbocharger);

- - the intake pipes of the charge air are clogged or pinched (between the turbocharger and the engine);

- - ingress of foreign objects between the air filter and the turbocharger;

- - blockage in the exhaust system;

- - air or exhaust leak between turbocharger and engine;

- - the crankcase of the turbine is damaged or clogged;

- - turbocharger wheel blades damaged;

- - incorrect operation of the turbocharger pressure control system (unloader valve).

Black exhaust smoke:

- - clogged air filter;

- - clogged or pinched air inlet pipes (between the air filter and the turbocharger);

- - the intake pipes of the charge air are clogged or pinched (between the turbocharger and the engine);

- - air or exhaust leak between turbocharger and engine;

- - damaged or clogged turbocharger;

- - incorrect operation of the turbocharger pressure control system (unloader valve).

Blue exhaust smoke:

- - clogged engine breather;

- - oil consumption;

- - fuel outlet pipe is damaged or pinched;

- - damaged turbocharger;

- - long engine idle;

- - pneumatic compressor is faulty.

Abnormal noise:

- - clogged air filter;

- - insufficient tightness of the connection between the air filter and the turbocharger;

- - clogged or pinched air inlet pipes (between the air filter and the turbocharger);

- - the intake pipes of the charge air are clogged or pinched (between the turbocharger and the engine);

- - ingress of foreign objects between the air filter and the turbocharger;

- - clogged or pinched exhaust system;

- - air or exhaust leak between turbocharger and engine;

- - insufficient lubrication of the turbocharger;

- - damaged turbocharger;

- - insufficient engine speed in relation to the load;

- - incorrect operation of the turbocharger pressure control system (unloader valve).

Excessive oil consumption:

- - clogged air filter;

- - clogged engine breather;

- - clogged or pinched air inlet pipes (between the air filter and the turbocharger);

- - insufficient lubrication of the turbocharger;

- - clogged or pinched oil outlet pipe;

- - turbocharger damage;

- - long engine idle;

- - defective pneumocompressor.

Presence of oil in turbocharger air intake pipes:

- - clogged air filter;

- - clogged or pinched air intake pipes (between the air filter and the turbocharger);

- - malfunction of the pneumatic compressor.

- Presence of oil in the air pipes after the turbocharger:

- - clogged air filter;

- - clogged engine breather;

- - clogged or pinched air intake pipes (between the air filter and the turbocharger);

- - clogged or pinched oil outlet pipe;

- - turbocharger damage;

- - long engine idling.

Exhaust manifold oil presence:

- - long engine idling.

Presence of oil in exhaust lines after turbocharger:

- - clogged engine breather;

- - clogged or pinched oil outlet pipe;

- - damaged turbocharger;

- - long engine idling.

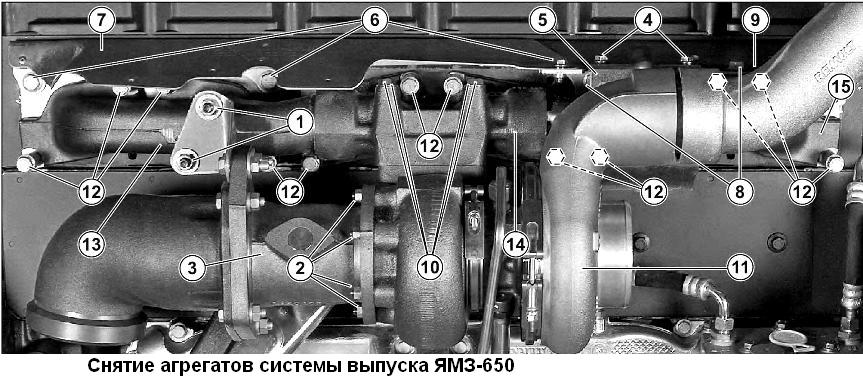

Removing the turbocharger (see Fig.1)

- 1. Unscrew the four bolts securing the turbocharger (10).

- 2. Remove turbocharger (11) (650.11180 11).

- 3. Remove the turbocharger gasket (650.1118158).

Turbocharger disassembly-assembly

Real operations are not difficult.

Purge the duct kit and make sure there are no foreign objects in them.

Before tightening exhaust manifold threaded fasteners, lubricate threaded fasteners with Loctite 8009 or Gleitmo165 heat-resistant lubricant or equivalent quality.

Tighten to recommended torque:

- - Studs for fastening the exhaust flap to the turbocharger (Loctite 8009 lubricant) 10 ± 2 Nm

- - Turbocharger fastening bolts on the exhaust manifold 60 ± 12 Nm

Replacing a turbocharger with an unknown cause can lead to new failures and serious engine damage.

It is forbidden to use sealing pastes on the fasteners of the turbocharger lubrication channels.

Before installing the turbocharger, pour fresh oil through the oil inlet and turn the rotor by hand to lubricate the bearings and thrust bearing.

After installing the turbocharger, start the engine and wait 30 seconds before revving up.

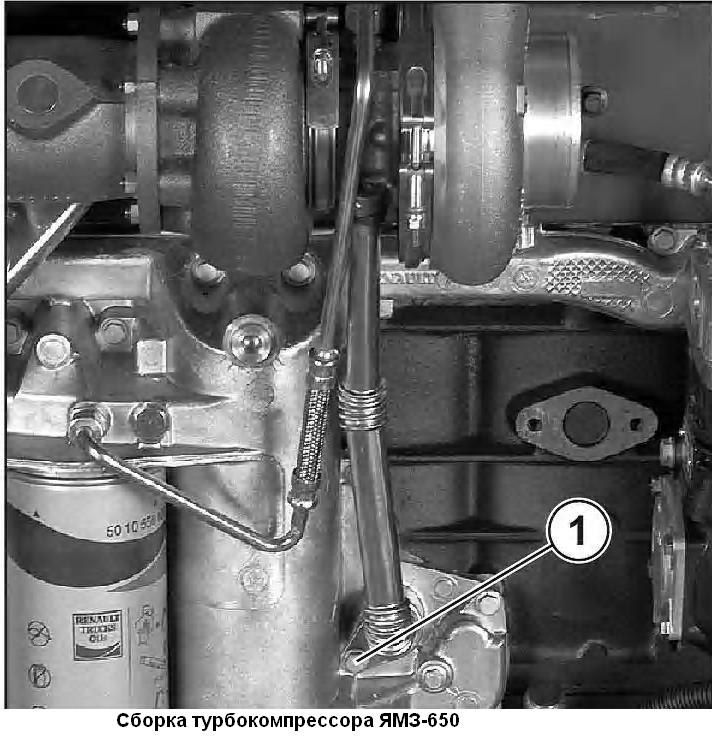

During assembly, it is necessary to strictly observe the specified length under the bolt head (1), corresponding to 60 mm (see Fig. 2).

Seal with Loctite 542 sealant

Turbocharger installation

Install the turbocharger in the reverse order of removal.

Apply Loctite 8009 lubricant to the threads of the bolts and tighten with a torque of Mcr = 60 ± 12 Nm, following the tightening sequence in a cross pattern.