The electric start system includes batteries, a starter, a battery mass switch, a lock-switch for instruments and a starter, an electric torch device (EFU), a vapor-liquid heater (PZhD), intermediate relays

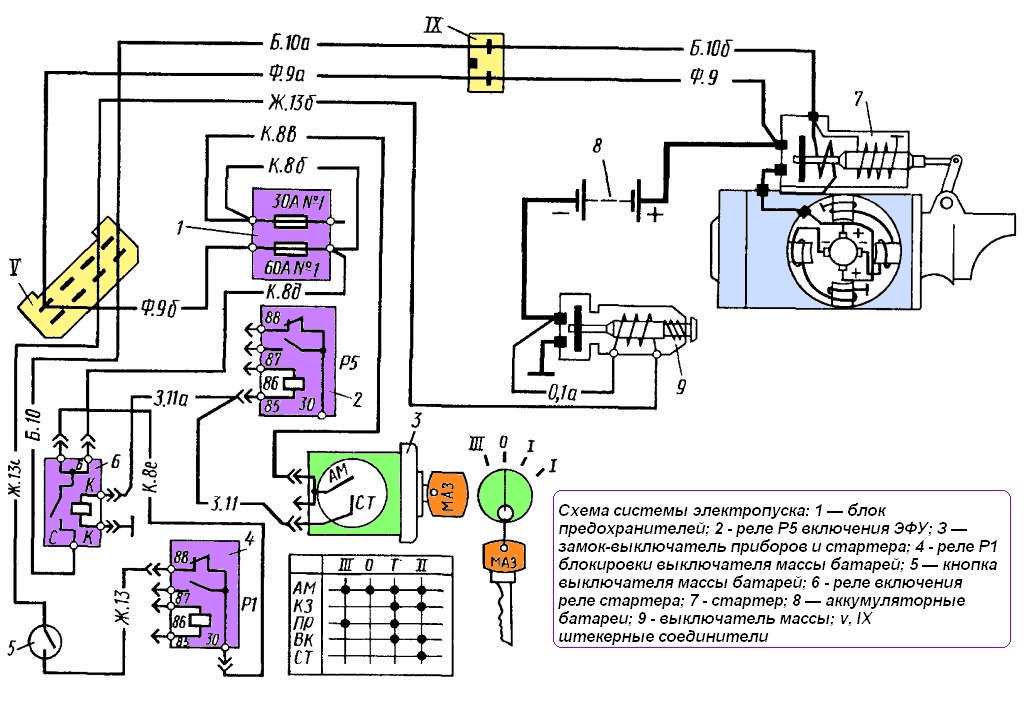

The electrical equipment of all these units and assemblies operates in the diagram shown in fig. 1.

On all the diagrams given in the section, the letters of the color of the wires are indicated: B - white, D blue; W - yellow; O - orange; P - pink; C - gray; Z - green; K - red; Kch - brown; H - black; F - purple.

In order to facilitate troubleshooting, the circuits on the diagrams also have a digital indication, which is also indicated on the wires.

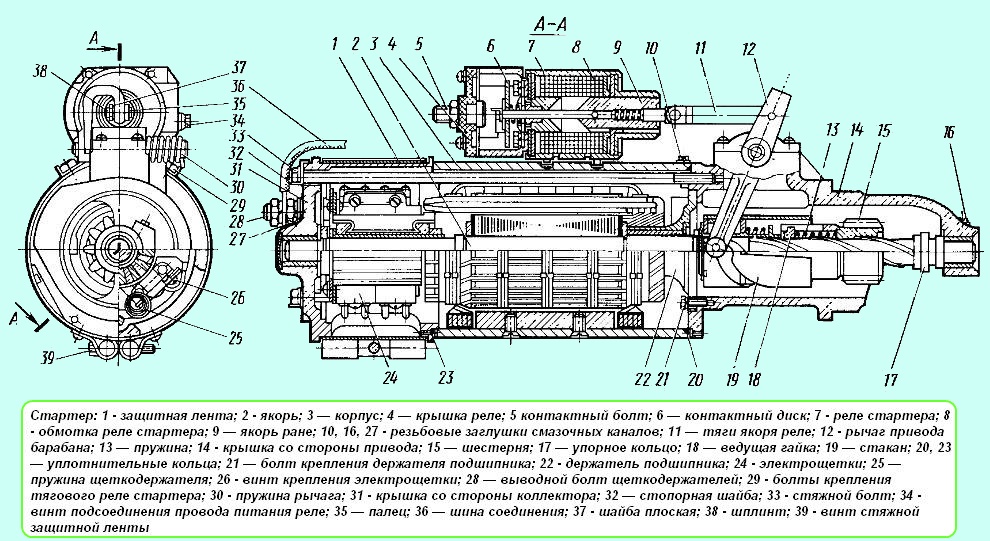

The starter is a series-excited DC electric motor with a gear drive mechanism mounted in a single unit with it.

The mechanism is controlled by a traction relay mounted on the starter housing.

Starter specification:

- - Type - ST 103A-01

- - Rated voltage, V - 24

- - Rated power, kW - 11

- - No-load current, A - 110

- - with a braking torque of 6 kgcm, A - 825

- - Voltage of switching on the traction relay. B - 20

- - brush spring pressure, kgf - 1.5

- - Starter weight, kg - 34

The starter device is shown in fig. 2.

The gear 15 of the drive is engaged with the flywheel ring using the traction relay 7.

The gear disengages automatically after starting the engine.

The starter is made according to a single-wire circuit, where the mass of the car serves as the second wire.

To ensure a reliable connection to the ground on the rear cover 31 of the starter there is a bolt 28 for connecting the flexible ground wire.

There are windows in the lid to access the electric brushes and inspect the collector. From the outside, the windows are closed with a protective tape 1. To lubricate the bearings on the covers and in the starter housing, channels are made with felt fillets placed in them.

The channels are closed with threaded plugs 10, 16 and 27. The starter is installed on the bed of the engine block and secured with two clamps.

A pin is pressed into the bed of the engine block, which ensures the correct installation of the starter and protects it from turning.

When the key of the lock-switch of the instruments and the starter is turned to position II (see Fig. 1), the contacts of the terminals "AM" and "CT" of the lock are closed and voltage is supplied to the intermediate relay 6 for starting the starter.

The relay closes the contacts of terminals B and C and voltage is supplied to the starter traction relay through wire B10.

The retracting winding of the relay moves the armature and through the lever 12 (see Fig. 2) feeds the gear to the flywheel crown. At the same time, the contacts of the traction relay are closed and the starter motor is turned on. The engine is cranking.

During the start-up process, the retracting winding of the traction wound is short-circuited (shunted) by the disk 6 of the relay armature, and the gear is held in the working position only by the field created by the holding winding, which consumes a small current.

After starting the engine, the gear is automatically disconnected from the flywheel crown, screwing along the oblique splines of the armature shaft.

The key of the lock-switch returns to working position I due to the lock springs, since the key position II is not fixed.

The traction relay cuts off the main operating current and the starter turns off.

At each TO-2, they check the tightness of the wires to the starter and battery terminals and clean these connections from dust, dirt and traces of oils;

Every 45 —- 50 thousand kilometers of a car's run it is necessary:

- remove the starter from the engine, inspect the condition of the collector, the working surface of which must be smooth and not burnt.

In case of contamination or burning, wipe the collector with a cloth soaked in gasoline or kerosene, followed by wiping. If the burn cannot be removed by wiping, clean the collector with fine sandpaper.

In case of severe burning, the anchor is removed and machined;

- - check the electric brushes for free, without jamming movement in the brush holder;

- - measure the height of the electric brushes and replace if necessary;

- - check the tightness of the screws that fasten the tips of the brush cords to the brush holders, and tighten them if necessary;

- - check the status of the starter relay contacts. When the working surfaces of the bolts and the disk are burnt, they must be cleaned and polished.sandpaper.

With a large burn, the contacts of the bolts and the disk can be cleaned with a file, followed by grinding with fine sandpaper. When cleaning, it is necessary to ensure that the parallelism of the contact surfaces of the bolts and the disk is not disturbed.

If the contact surfaces of the bolts are significantly worn, they must be rotated around their axis by 180˚ and the contact disk turned over to the other side.

Clean up the existing melting around the perimeter of the bolts and the disk with a file. The contact disk must rotate freely on the armature rod;

- - check the reliability of fastening the traction relay to the starter housing. If necessary, tighten the fixing bolts and lock them with lock washers;

- - pour 10 drops of turbine or engine oil into oilers;

- - wipe the starter with a rag.

If during an external examination and inspection of the brush-collector assembly it turns out that the condition of the starter is good, then the starter should not be disassembled.

It is only necessary to lubricate the bearings, pour 10 drops of oil into them, wipe the starter, check the adjustment of the traction relay, after which the starter can be installed on the engine.

Possible starter malfunctions and how to fix them

- Cause of failure

Remedy

Starter armature does not turn, starter relay does not operate

- Fuse No. 1 blown

Replace fuse

- Faulty intermediate relay 6 (see Fig. 1)

Check and replace relay

- Batteries are discharged

recharge batteries

- Breakage of the retracting winding of the traction relay 7 (see Fig. 2)

Check relay and replace

- Breaks in the wires in the starter circuits

troubleshoot

Starter relay energizes, but starter armature does not turn (vehicle headlights dim when starter is turned on)

- Poor contact at the battery output terminals or at the starter terminals

Clean the battery terminals and tighten the bolts

Tighten the bolts securing the wires to the starter

- Batteries are discharged

Recharge batteries

- Short circuit inside the starter

Remove and repair the starter

Starter relay energizes, but starter armature does not rotate (vehicle headlights do not dim when starter is turned on)

- Break connections inside the starter

Remove and repair the starter

The starter turns the engine slightly

- Low engine temperature (in winter)

Warm up the engine

- Discharged or defective batteries

Check and recharge batteries

- Burning of the contacts of the traction relay 7 (Fig. 2)

Remove starter and clean relay contacts

Starter armature rotates at high speed but does not crank engine

- Breakage of the teeth of the flywheel crown

Change flywheel ring

- The lever is bent or the lever finger 12 is broken (see Fig. 2)

Repair or replace lever

- Starter drive adjustment is broken

Adjust Drive

The starter traction relay works intermittently (turns the starter on and off immediately)

- Break of the holding winding of the traction relay

Replace relay

- Short circuit in the starter

Remove and repair the starter

The drive gear does not systematically engage with the flywheel crown during normal operation of the traction relay

- The ends of the teeth of the flywheel crown are clogged

Clean teeth

- Violated starter adjustment

Adjust the starter drive

- Gear seizing on the shaft due to coking of lubricant on the splines of the armature shaft

Clean the splines from coked grease and lubricate the shaft with CIATIM-203 grease