The vehicles are fitted with a three-blade windshield wiper

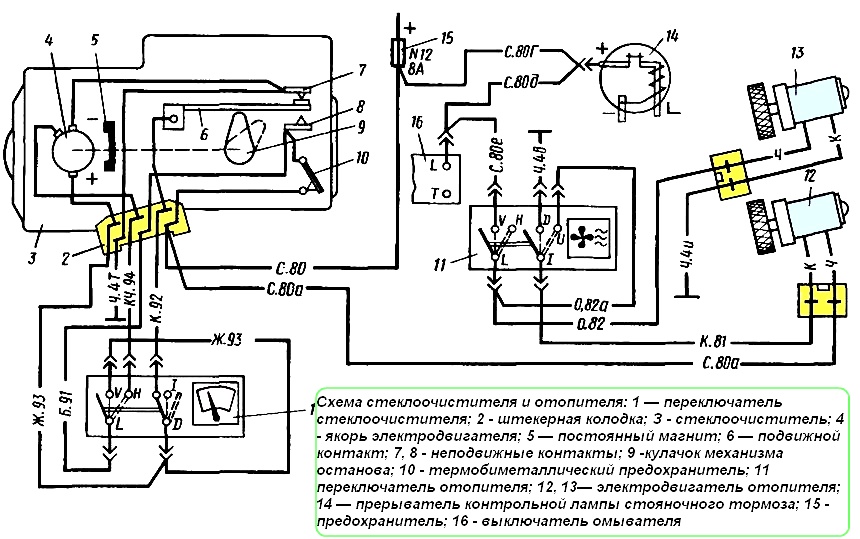

The wiper is turned on by switch 1 (Fig. 1), which has three positions:

Off, Low speed on, High speed on.

When the first (low speed) is turned on, contacts "L" and "V", as well as "D" and "I" of switch 1 turn on.

Voltage is supplied through the gray wire to the thermobimetallic fuse 10 and from it to the fixed contact 8. Then the current flows to the plug-in block and from it through the white wire to the “L” terminal of the switch.

From the “L” terminal, the current flows to the “V” terminal, through the yellow wire it goes to the “D” terminal, and through the plug block to the positive electric brush of the motor armature.

After passing through the armature, the operating current enters the fixed contact 7 and from it through the plug-in block along the black wire goes to ground.

From the interaction of the magnetic fields of the permanent magnet 5 and the magnetic field of the armature, the latter begins to rotate. At the same time, cam 9, mounted on the worm gear of the wiper gear, rotates, closing and opening contacts 6, 7 and 8.

When the second, increased speed is turned on, the contacts of the terminals "L" and "H" of switch 1 are closed, the contacts of the terminals "D" and "I" are opened, the operating current is no longer supplied to the positive terminal of the armature, but through the brown wire to an additional electric brush , which leads to a decrease in the working turns of the armature and, consequently, to a decrease in the magnetic field of the armature, as a result of which the frequency of rotation of the armature increases.

When the wiper is turned off, the circuit of the terminals “L” and V” of switch 1 is interrupted, but the armature 4 of the electric motor continues to rotate, since power is supplied to it through closed contacts 6 and 8 to the plug block, from it through the red wire to switch 1, through it - to the "D" terminal, from which the current passes through the yellow wire to the positive electric brush of the armature, through the armature - to the negative brush, to pin 7 and from it to ground.

The armature rotates until cam 9 opens contacts 6 and 8. This position of the cam corresponds to the position of the wiper blades at the bottom of the car's windshield.

Due to the inertia of the armature, the latter can make a few more turns before stopping, which will lead to the brushes moving up the windshield, which will interfere with the driver.

In order to eliminate this phenomenon, contact 7 was introduced, when it is closed with contact 6, the armature electric brushes are shunted to each other, which is easy to follow from the diagram.

When shunting, the armature stops abruptly, which ensures that the brushes are laid strictly in the specified position.

In the cabin heating and ventilation system, two electric motors are installed, which turn on at low and high speeds, which changes the performance of the fans.

In the first position of switch 11, both motors operate at high speed, as they are connected in parallel. In the second position, both motors are connected in series.

Wiper Maintenance

Wiper motors and heating systems are not subject to maintenance during operation.

Possible wiper malfunctions and solutions

- Failure Cause

Remedy

Wiper not working

- Fuse No. 12 blown

Replace fuse

- Fault in the circuit

Check the circuits according to the scheme

Troubleshoot

- Wear of electric brushes

Disassemble the motor and replace the electric brushes

Wiper blades don't stop in down position

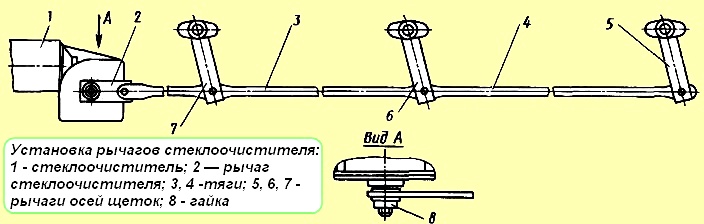

- Lever system installed incorrectly

Set the rods according to the picture

- Contacts of the stop system are faulty

Remove wiper, inspect contacts and repair

Wiper intermittent operation

- The nut on the wiper arm drive shaft has loosened

Tighten nut 8 (see figure)

If the windshield wiper fails, first make sure that fuse No. 12 is working and that there is voltage on the gray wire in the windshield wiper plug.

If the voltage on the prthere is a water, then the serviceability of the fuse 10 (see Fig. 1) installed on the wiper body is checked. If there is voltage, then you should check the serviceability of switch 1.

After making sure that the switch is working, the wiper must be removed and repaired.

Possible malfunctions of additional equipment and ways to eliminate them are shown in the table.

Repair

At the wiper, after disassembly, the anchor, electric brushes, the contact system of the stop mechanism and the worm wheel of the gearbox are inspected.

When the teeth of the wheel are worn, it is replaced with a new one. The contacts of the stop mechanism are being cleaned.

Electric brushes are replaced with new ones when worn.

The anchor is inspected and, if necessary, the collector is machined and polished.

When installing a windshield wiper on a car after repair or when installing a new wiper, install the lever system as shown in the figure, i.e. extended in one line.

Failure to follow this rule will cause the wiper to malfunction or fail.