When we replace the generator belt or when repairing the engine, it is necessary to check the condition of the generator tensioner roller

The roller should rotate easily and silently, there should be no traces of grease from the roller

To replace the roller, you need to loosen the tension on the generator drive belt.

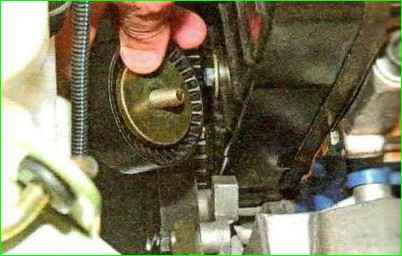

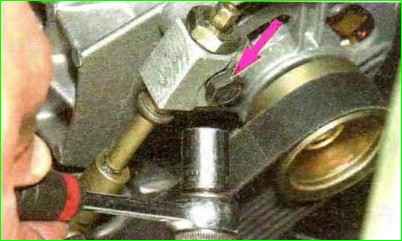

Pry off the roller cover with a screwdriver (shown on the removed tensioner)

Remove the roller cover

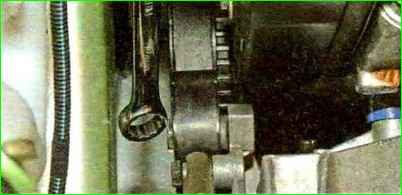

Use a spanner wrench or a 17mm socket to unscrew the bolt securing the roller to the lower bracket of the tensioner (the bolt thread is left-handed, so unscrew the bolt clockwise)

For clarity, we show it on a removed tension device

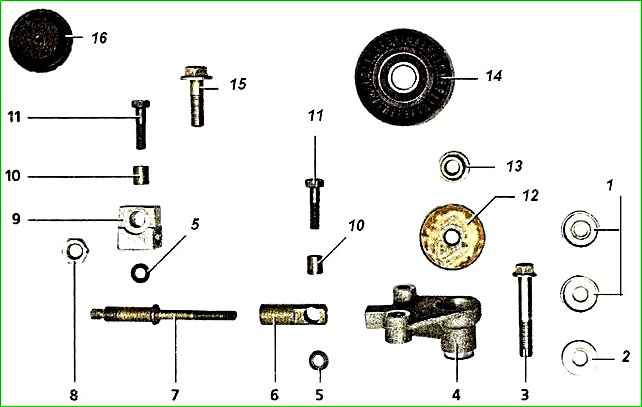

Remove the tension roller with the bolt, support sleeve and washer

Install the tension roller in reverse order

To completely remove the tensioner, loosen the belt tension.

Using a 13mm socket, unscrew the bolt securing the upper tensioner bracket to the generator bracket.

Remove the washer from the bolt (located on the inside of the tensioner bracket), remove the bolt and bushing.

Using a 13" socket, unscrew the bolt securing the lower bracket of the tensioner to the generator bracket (shown for clarity on a dismantled engine).

Remove the tensioner assembly.

Remove the bolt securing the lower bracket of the tensioner by removing the spacer and two cup washers from it.

If necessary, disassemble the tensioner of the generator drive belt.

Assemble and install the tensioner in the reverse order