Centralized system for regulating air pressure in Kamaz tires

The tire pressure regulation system is used on KamAZ-4310 vehicles and is designed to increase the vehicle's cross-country ability on difficult sections of the road by changing the air pressure in the tires

In the event of a tire puncture, this system allows you to continue short-term driving to a parking spot without changing the wheel, provided that the compressor can replenish the air leak from the damaged tire.

The system is controlled from the driver’s cabin; the air pressure in the tires is constantly monitored by a pressure gauge located on the instrument panel and must be maintained within normal limits.

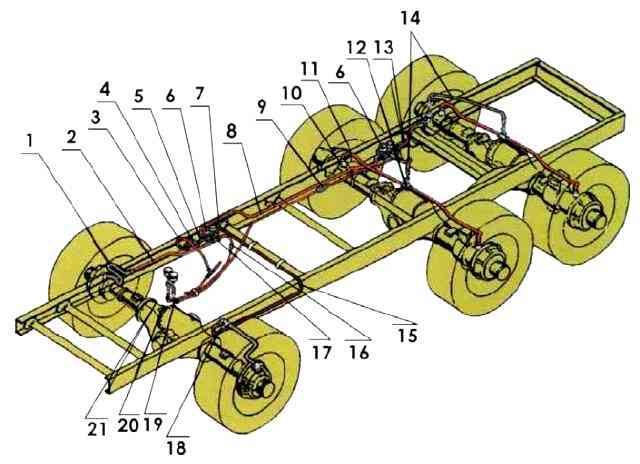

The regulation system includes pressure control valve 1 with a limiting valve that protects the pressure in the pneumatic system from falling below 550 kPa, air lock valves 3, pneumatic lines, air supply heads.

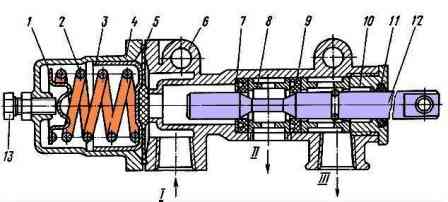

Tire pressure control valve is of the spool type.

Spool 12 moves in housing 6 and is sealed with oil seal 9.

The thrust ring located on the spool limits the extreme limits of the spool stroke.

The spool is connected through a pin to the rod of lever 2 of the valve, which has three positions.

The left position of the lever corresponds to inflating the tires, the middle position is neutral, the right position corresponds to releasing air from the tires into the atmosphere.

When the valve lever is moved to the left position, the spool moves to the limiting valve, the groove on the spool is installed against the oil seal and air enters the tires through the gap formed under the oil seal.

When the valve lever is moved to the right position, the spool moves away from the limiting valve, the groove on the spool is installed against the other oil seal and the air from the tires escapes into the atmosphere.

When the valve lever is moved to the neutral position, the groove on the spool is located between the seals and prevents the flow of air to the tires and from the tires into the atmosphere.

The crane control handle is installed under the dashboard on the right side of the driver.

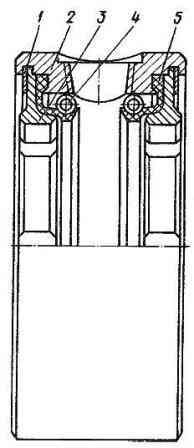

The air supply heads, installed on the axle shafts, consist of a housing and two rubber cuffs with springs that ensure the tightness of the movable joint.

Air enters the head through the fitting. From the cavity of the head, air passes through the channel in the axle shaft through the air shut-off valve and the connecting hose and enters the wheel tire.

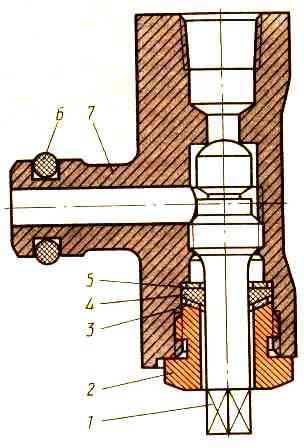

Air shut-off valves are installed on each wheel, designed to disconnect the tires from the system when the vehicle is parked for a long time and in the event of failure of the air supply head cuffs.

The tap consists of a body 7, in which plug 1 moves along the thread, its outer end has a square head for a key.

The plug is sealed with a rubber ring 4 with washers 3 and 5 and tightened with a nut 2. The seal of the valve body in the axle shaft seat is ensured by a rubber ring 6.

Driving a vehicle on paved roads and compacted dirt roads is allowed only with an air pressure in the tires of 300-340 kPa, since this pressure ensures the safety of the tires.

On difficult sections of the route, a short-term decrease in air pressure in the tires is possible.

At the same time, the maximum speed movement must comply with the standards given in the table.

Norms for choosing the maximum speed

Table 1

Terrain character - Tire pressure, kPa - Maximum speed km/h:

- Virgin snow, marshy soil - 80 - 10;

- Loose sand, loose soil, damp meadow - 120-170 - 20

After overcoming difficult areas, you need to increase the tire pressure (> 170 kPa), which allows you to move at a higher speed.

To reduce the pressure to 80-170 kPa, you must stop the car.

While driving, the wheel valves must be fully open, and during long periods of parking, in order to avoid air leakage through leaks in the pipelines, they must be closed.

The air pressure in the tires is determined by a pressure gauge with the wheel valves open.

If there is a drop in pressure, then by closing all the valves and then opening them one by one, you need to determine which tire is leaking air.

When the air shut-off valves are closed, it is not allowed to move the handle of the pressure control valve to the position corresponding to inflating the tires, in order to avoid damage to the tire pressure gauge.