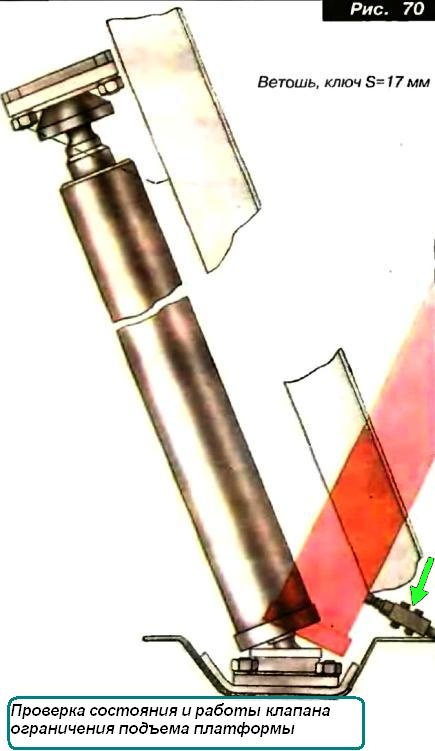

Check the condition and operation of the platform lift limit valve.

Fix the lift limit valve to the subframe cross member bracket. The valve stem must not be twisted

The adjusting screw must be securely locked with the locknut.

To adjust the angle of elevation of the vehicle platform—KAMAZ dump truck—55111, do the following:

- - unscrew the locknut of the adjusting screw of the lift limit valve;

- - screw the adjusting screw into the stem until it stops; raise the platform to a position where the locking pins freely enter the holes of the subframe brackets, and lock the platform in this position with the locking pins;

- - unscrew the adjusting screw from the valve stem until it stops in the hydraulic cylinder body and lock it with a lock nut.

Unlock the platform, lower it and raise it again.

Make sure that the lifting of the platform stops when the axis of the locking pins coincides with the axes of the holes in the subframe brackets.

To adjust the angle of elevation of the platform of the vehicle—dump truck mod. 55102 you need to perform the following operations:

- - raise the platform to the left at an angle of 48-50° and place a technological stop under it;

- - unscrew the lock nut of the adjusting bolt and unscrew or screw in the bolt so that the angle of elevation is equal to the specified one, then tighten the lock nut; in the same way, adjust the amount of platform lift to the right;

- - lower and raise the platform again: make sure that its rise is limited to an angle of 48-50°.

Pay attention to the position of the lever when the platform is lowered.

It should be spring-loaded against the restrictor valve adjusting screw. Otherwise, adjust the spring tension.

Fig. 2. Check the condition and operation of the platform lifting control crane.

Air leaks (check by ear) and oil are not allowed.

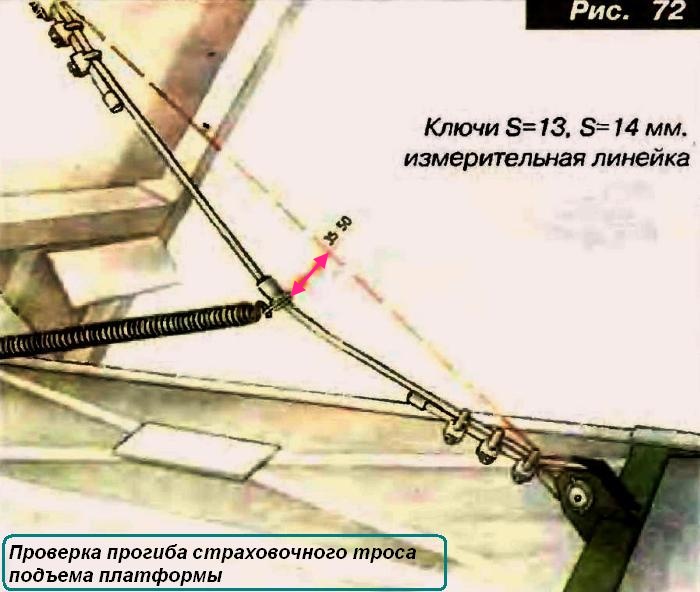

Fig. 3. Check the deflection of the platform lifting safety cable.

Deflection should be 35-50 mm.

Adjust the deflection by loosening the cable clamps.

The cable should not have strand breaks.

Fig. 4. Fix the front subframe brackets.

Nut tightening torque - 79-98 Nm (8-10 kgf m).

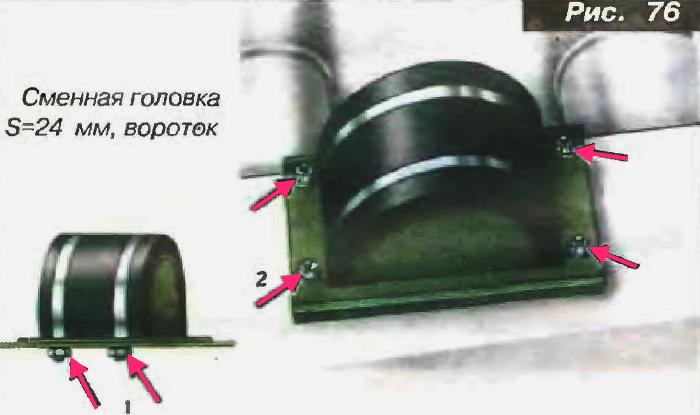

Fig. 5. Fasten the subframe pinch bolts.

Tightening torques for nuts 1 of the subframe mounting bolts M12 - 79-98 Nm (8-10 kgf m), nuts 2 of the subframe coupling bolts M16 - 176-216 Nm (18-22 kgf m), bolts M14 - 137-157 Nm (14—16 kgf m).

Fig. 6. Fix the power take-off and oil pump.

The tightening torque of the bolts is 39-49 Nm (4-5 kgf-m).

Fig. 7. Fix the catcher-shock absorber.

The tightening torque of the nuts of 1 clamps is 54-62 Nm (5.5-63 kgf-m).

Tightening torque for nuts 2 bolts - 137-147 Nm (14-15 kgf-m).

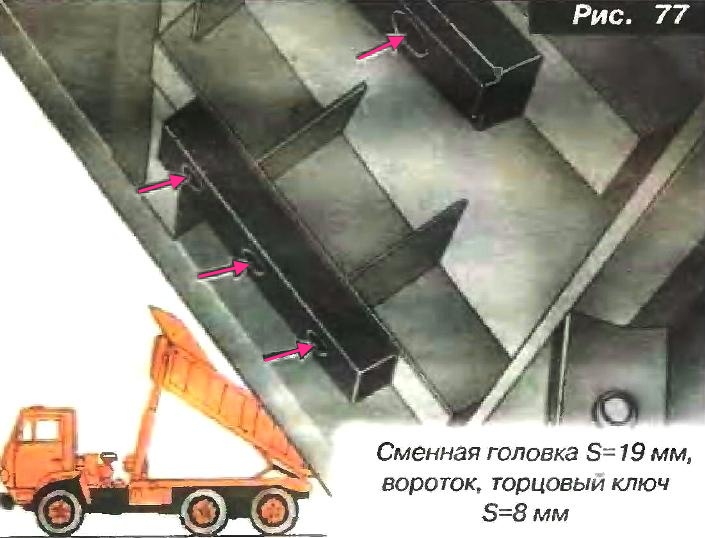

Fig. 8. Attach platform shock absorbers.

Tightening torque for bolt nuts is 44-53 Nm (45-54 kgf-m).

Drain the sediment from the hydraulic cylinder of the platform lifting mechanism (for the KamAZ-55102 car).

Change the oil in the hydraulic system of the platform lifting mechanism.

The oil level in the tank is checked with the platform lowered by a pointer mounted in the tank cover. The level should be between the H and B marks on the pointer.

To refuel the hydraulic system:

- - unscrew the cap of the oil tank, remove, rinse and re-install the strainer;

- - fill in oil up to mark B, printed on the oil level indicator;

- - raise and lower the platform 3-4 times at an average engine speed (1100-1300 rpm) to remove air from the system;

- - check the oil level, if necessary top up to mark B.

Possible malfunctions of the mechanism for raising and lowering the platform and how to eliminate them

Fault

- Cause of malfunction

Remedy

Power take-off does not turn on

- Open circuit of the electro-pneumatic valve

Fix break

- Electropneumatic valve stem sticking

Disassemble the electro-pneumatic valve, eliminate the cause of jamming

Power take-off does not turn off

- Electropneumatic valve stem sticking

Disassemble the electro-pneumatic valve, eliminate the cause of jamming

The platform is not held in the raised position when the control valve switch is in neutral position

- Ingress of foreign particles under the valves of the control valve

Turn on the lifting mechanism several times and bleed the system at an average engine speed.

If this does not resolve the problem, remove the faucet or valve and flush it.

Change the oil

- Electropneumatic valve stem sticking

Disassemble the electro-pneumatic valve, eliminate the cause of jamming

Lifting platform is not limited

- Violation of platform elevation adjustment

Adjust elevation

The platform does not go down

- Break in the circuit of the electro-pneumatic valves of the control valve

Fix break

- Seizure of electropneumatic valve stems

Disassemble the electro-pneumatic valves, eliminate the cause of jamming

- Rupture of the membrane of the pneumatic chamber of the control valve

Replace membrane

- Air leak

Retighten pneumatic line connections

Slow or uneven platform lift

- Oil leakage through the drain valve in the control valve or the lift limit valve as a result of foreign particles entering under the valve

Turn on the platform lift mechanism several times and bleed air from the system at an average engine speed.

If the problem persists, remove the faucet or valve and flush it. Change oil

- Reduce pump flow

Replace pump

- Inconsistency with the season of operation of the oil with which the hydraulic system is filled

Pour in appropriate oil

- Air entering the hydraulic system

Check the tightness of the suction line.

Remove air leaks.

Remove air from the hydraulic system by raising and lowering the platform 3-4 times

The platform does not rise

- Platform overload

Partly unload platform manually

- Open circuit in the control valve electropneumatic valves

Fix break

- Air leak

Retighten pneumatic line connections

- Seizure of electropneumatic valve stems

Disassemble the electro-pneumatic valves, eliminate the cause of jamming

- Rupture of the membrane of the pneumatic chamber of the control valve

Replace membrane

Oil leak from the holes communicating the control valve and distributor with the environment

- Increased wear of tappet seals in the tap or valve seals in the distributor

Replace tappet or valve seals

Oil leak through hydraulic cylinder seals

- Wear or destruction of sealing collars

Replace seals