Disassembly of the complete axle with brakes and hubs (GAZ-53A).

- 1. Remove the axle shafts using the removal bolts.

- 2. Remove the axle flange gasket.

- 3. Remove the brake drum and hub assembly.

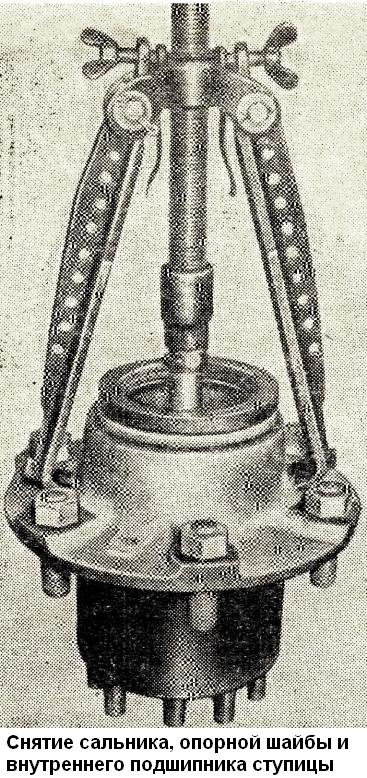

- 4. Remove the oil seal, thrust washer and inner hub bearing (Fig. 1).

- 5. Remove brake assembly and oil deflector.

- 6. Remove the bolts securing the gearbox to the rear axle housing.

- 7. Remove gearbox.

- 8. Remove the breather.

Disassembling the GAZ-66-02 rear axle with brakes and hubs as an assembly

- 1. Remove the axle shaft flange cover and gasket, remove the axle shaft.

- 2. Remove hub with drum, inner hub seal and thrust washer.

- 3. Remove wheel bearings.

- 4. Remove the protective sleeve from the brake disc and the protective sleeve from the outer seal housing.

- 5. Remove the hub outer oil seal, brake pads, trunnion assembly with oil seal block and gasket.

- 6. Unscrew the flexible hose from the stuffing box and separate the stuffing box and trunnion.

- 7. Pull out the gearbox using the removal screws.

Disassembling the rear axle gearboxes of GAZ-53A and GAZ-66 cars

- 1. Unscrew the oil scraper plug, remove the lock plate.

- 2. Remove the tube, spring, plate from the oil channel.

- 3. Unscrew the adjusting screw of the driven gear stop.

- 4. Remove lock plates and differential bearing caps.

- 5. Remove the differential bearing outer races and their adjusting nuts.

- 6. Remove the differential assembly from the crankcase.

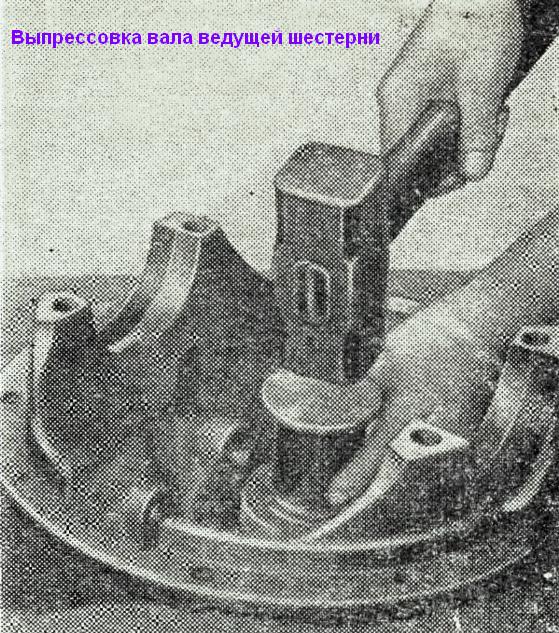

- 7. Remove the drive gear shaft assembly from the gearbox housing (Fig. 2).

- 8. Remove shims from the crankcase neck.

- 9. Remove the driveshaft flange, differential front cover and gasket.

- 10. Remove the bearing sleeve together with the inner race of the front roller bearing.

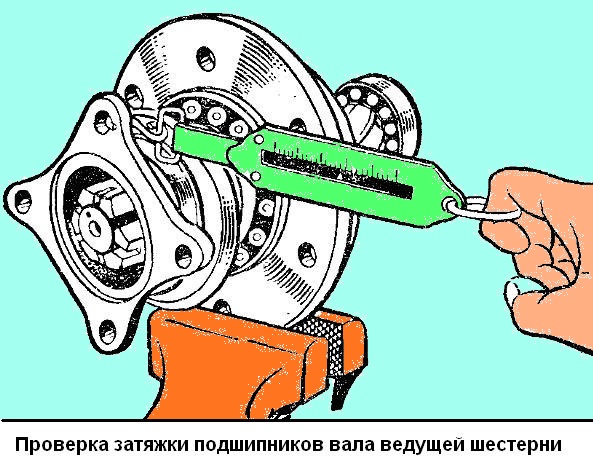

- 11. Remove spacer ring, shims and rear roller bearing inner race (fig. 3).

- 12. Press the drive gear shaft oil seal out of the front differential cover.

If the outer race of the taper bearing of the pinion shaft is unsuitable, it must be removed.

Disassembling the differential of the GAZ-53A car

Remove the driven gear from the pinion box, disconnect the oil catcher

Remove differential bearings (fig. 4)

Remove the pinion box bolts, separate the pinion box, remove the support washers, pinion pinions, axle gears and crosspiece

Disassembling the differential of the GAZ-66 car

Disconnect the cup and differential cage.

Remove the driven gear from the cup.

Remove the differential bearing inner race from the cup.

Remove the outer and inner sprockets.

Remove the inner retaining ring (Fig. 5) and crackers and remove the outer retaining ring from the cage.

Remove the differential bearing inner race from the cage.

Determining the technical condition of parts

General requirements for the technical condition of the rear axle parts are similar to the requirements for the condition of the gearbox parts.

Gears. Inspect the drive and driven gear teeth for nicks or excessive wear.

Worn out gears cannot be restored. Scuffed gears are also not suitable for further work.

Inspect the teeth and bearing surfaces of the differential gears. Side gear journal wear can cause increased noise during axle operation.

Worn splines, bearing surfaces, or bearing washers cause large gear play.

Bearing outer races. Inspect bearing races for burrs or uneven wearsa.

Check with a feeler gauge the tightness of the bearings between the ring and its thrust shoulder, the feeler gauge 0.03 mm thick should not pass.

Inner ring and bearing rollers. Check the wear of the roller ends.

Stepped wear on the ends of the rollers indicates insufficient preload of the bearings or a slight misalignment of the rollers.

In the absence of discoloration and scuffing, bearings with such rollers can be used.

Rejection signs indicated for gearbox bearings also apply to rear axle bearings.

Differential bearing adjusting nuts. Temporarily install the bearing cap and check that the nuts are screwed in.

The ends of the nuts in contact with the bearings must be perpendicular to the axis of the thread. The runout of these ends relative to the axis of the thread is not more than 0.03 mm.

The surface of the ends must be clean. Make sure the bearing caps are installed on the side they were machined on.

Gimbal flange. The ends of the flange in contact with the front bearing of the pinion shaft and with the washer must be smooth and comply with the sixth grade. The non-perpendicularity of these ends to the axis of the slotted hole should not exceed 0.05 mm.

Checking the runout of the driven gear. Check the runout of the driven gear as shown in fig. 6. allowable runout 0.15 mm.

If during inspection it turns out that the runout exceeds the specified value, then it can be assumed that there is a deformation of the gear, damage to the satellite box, or excessive wear on the bearings. Replace unusable parts.

Rear axle assembly

The rear axle is assembled in the reverse order of disassembly. In this case, the following should be taken into account.

When reassembling a pinion shaft with a cylindrical bearing, insert the retaining ring of the bearing into the groove and crimp it.

When repairing the bearing coupling, it should be noted that at the factory, after boring the bearing seats and pressing the outer rings of the bearings into them, the coupling is processed on the basis of these rings.

Therefore, when repairing the bridge, if possible, use a coupling without pressing out the outer races of the bearings

Press the inner ring of the rear roller bearing of the drive gear shaft into the end of the ring gear as far as it will go.

A feeler gauge 0.03 mm thick should not pass between the ends of the crown and the bearing.

When reassembling the drive gear shaft, the thickness of the shim package is selected approximately.

Shims are installed between the ends of the inner ring of the rear roller bearing and the spacer ring.

Before assembling the differential of the GAZ-53A car, the rubbing surfaces of the differential parts are lubricated with hypoid grease.

The inner rings of the differential bearings are pressed onto the necks of the satellite box until they stop.

A feeler gauge 0.03 mm thick must not pass between the ends of the bearings and the satellite box.

The bolts of fastening the driven gear to the satellite box are tightened (torque 7-11 kGm).

The spherical recesses on the support washers of the gears of the axle shafts must face the gears.

The right and left cups of the satellite box are connected so that the numbers indicated on them are the same and located one against the other.

After assembling the differential, check the rotation of the differential gears behind the axle gear using a splined mandrel. It should be smooth, without jamming.

Assembling the differential of the car GA366

- 1. Lubricate the differential parts with hypoid grease before assembling.

- 2. Install the outer retaining ring on the separator until it stops against the collar. Place the crackers in the holes so that the protrusions on the crackers rest against the retaining rings.

- 3. Install the inner retaining ring between the rows of crackers, after squeezing it. At the same time, ensure that the crackers slide freely (under their own weight) in the holes of the separator.

- 4. Insert an inner asterisk into the separator.

- 5. Install the crackers of the inner row (from the side of the neck under the bearing) along the cams of the inner sprocket so that the radius protrusions of the crackers are on the same circle, and the crackers of the outer row are located so that six crackers enter the sprocket depressions, and six crackers stand on its ledges.

- 6. Install the outer sprocket of the differential on the crackers inserted into the cage.

The side clearance in the meshing of crackers and cams of the sprockets in the new differential should be in the range of 0.3 - 1.6 mm, measured at a radius of 62 mm.

The assembled differential is checked for contact between crackers and sprockets. The area of contact of crackers should be at least 75%.

To check the side clearance and contact, one sprocket, for example, an external one, ozit with a mandrel inserted into its slotted hole, and turn the other (inner) one with a slotted mandrel from one extreme position to another.

Before checking the contact, cover the working surfaces of the cams with a thin layer of paint.

Press on the cup and on the separator the inner races of the differential bearings until they stop against the collars on the necks; at the same time, a 0.03 mm thick probe should not pass between the ends of the bearings and the support collars on the cup and cage.

Tighten the bolts securing the driven gear to the cup and separator (torque 7 - 11 kgm).

Reducer Assembly

Install gaskets with a total thickness of 1.5 mm between the ends of the neck of the gearbox housing and the flange of the bearing coupling (for an assembly with new bearings).

Fix the coupling with bolts (tightening torque 10 - 12 kgm).

When disconnecting the differential bearing caps, do not confuse these caps with others, as they bore and cut the threads in the crankcase assembly with the caps.

When installing the differential assembly, keep the completeness of the selected gears of the main pair (the serial numbers of the driving and driven gears must be the same).

Tighten the bolts of the differential bearing cover (torque 20 - 23 kgm).

Adjust differential bearing preload, backlash and gear engagement.

To ensure the required clearance between the stop adjusting screw and the driven gear, turn the screw all the way down, then unscrew it by 1∕6 turns and lock it.

Insert the oil scraper tube into the oil channel so that its side hole coincides with the channel of the gearbox housing.

Run in the gearbox and check it for noise in forward and reverse motion.

Assembly of the rear axle of the GAZ-53А car

Place the gearbox housing gasket on the sealing paste on the flange of the rear axle housing.

The tightening torque of the bolts for fastening the gearbox to the rear axle housing is 10-12 kgm. Lubricate the threaded part of the bolts with sealing paste before installation.

Fill oil through the hole in the neck and rotate the drive shaft of the gearbox for 0.5 min to lubricate the gears.

Install the brake assembly on the flanges of the half axle housings so that the long friction brake lining is directed forward along the vehicle.

Place an oil deflector on each side with the visor down.

After installing the hubs with brake drums, pour grease into the cavity of the hubs.

Adjust the tightening of the hub bearings as follows (adjust before installing the wheels):

- - turning the brake drum with the hub by hand, tighten the bearing fastening nut until the brake drum begins to rotate tightly. Turning is necessary to ensure the correct position of the rollers in the bearings;

- - loosen the nut ⅛ turn;

- - install the lock washer and make sure that the mounting pin on the neck fits into one of the slots in the lock washer. If the pin does not go into the slot, turn the nut in one direction or another so that the pin goes into the nearest slot in the lock washer;

- - tighten the locknut;

- - check the adjustment of the bearings after tightening the locknut.

When properly adjusted, the brake drum should rotate freely without jamming the axial and radial play.

Place the axle flange gasket on the sealing paste.

Insert and secure the axle shafts. The tightening torque of the nuts of the studs for fastening the axle shafts is 12-14 kgm.

Pour lubricant into the bridge.

Check the rear axle assembly for noise, heating and oil leakage when the drive gear shaft rotates at 1000, 1500 and 3000 rpm, both at idle and with braking of the rear axle axle shafts. In this case, the torque on the drive gear should be within 2-3 kgm.

Small uniform noise is allowed without howling, metallic knocks and rattles.

Oil leakage is not allowed.

When assembling the rear axle of the GAZ-66-02 car, press in the axle shaft seals (at the beginning of the assembly).

After adjusting the tightening of the hub bearings of this axle, you must:

- - install and bolt the axle shaft flange cover, having previously installed the sealing ring in the groove;

- - screw the air supply fitting to the wheel to the crankcase of the rear axle, screw the flexible hose into the fitting;

- - check the trunnion gland block for tightness in a water bath under air pressure of 3-4 kg/cm2. Leakage of air through the seals of the block and in the connection of the flange cover with the axle shaft is not allowed.

Pour lubricant into the bridge and run it in according to the regime for the GAZ-53A rear axle.

Rear axle adjustment

Rear axle bearings, side clearance and gear engagement do not require adjustment in service. Their adjustment is only necessary when replacing any parts or when the bearings are heavily worn.

Enlarged lateral The gap between the teeth of the gears of the main gear, resulting from the wear of the teeth, cannot be reduced by adjustment, since in this case the position of the gears in which they have run in will be disturbed.

This will increase noise or break teeth.

Remove the backlash in the tapered bearings without disturbing the position of the driven and driving gears that have run in to each other.

Adjusting the tightening of the pinion shaft bearings

If the axial play of the pinion shaft exceeds 0.03 mm, tighten the bearings by removing the shims installed between the spacer ring and the rear roller bearing inner race.

Check the axial play using an indicator device by moving the drive gear shaft from one extreme position to another. If there is no fixture, check by shaking the flange by hand.

If there is axial play in the pinion shaft in the tapered bearings, be sure to tighten the bearings.

The order of adjustment is as follows:

- 1. Detach the rear end of the driveshaft.

- 2. Take out the axle shafts.

- 3. Remove gearbox.

- 4. Unscrew the stop screw of the driven gear so that the end of the stop does not protrude above the end of the lug in the gearbox housing.

- 5. Remove the oil scraper pipe.

- 6. Loosen the differential bearing nuts -

Before loosening the nuts, note their position relative to the differential bearing caps by marking the caps and nuts.

- 7. Remove differential bearing caps.

- 8. Move the differential towards the driven gear and remove it.

- 9. Remove the coupling.

- 10. Check, without disassembling the coupling, whether there are enough spacers between the bearings. To do this, clamp the coupling flange in a vice, and tighten the propshaft flange fastening nut until it stops.

If there are not enough spacers, then tightening the nut will cause the bearings to be tightened, and the pinion shaft will turn very tight or not at all.

In this case, further adjustment comes down to choosing the right thickness of the gaskets.

This is achieved in several steps by adding or removing shims so that there is a slight interference in the bearings.

- 11. Unscrew the cardan flange nut, remove the flange, stuffing box cover and inner ring with rollers of the outer bearing.

- 12. Remove or add one or two spacers as needed.

- 13. Assemble the clutch in a vice in the reverse order, but without the stuffing box and in front of it the cover and tighten the nut until it stops. When tightening the nut, turn the flange so that the bearing rollers are in the correct position in both races.

At the end of the adjustment, the nut is tightened to failure, and one of its slots must coincide with the hole for the cotter pin.

You can't even turn it back a little to match the cotter pin hole with the nut slot.

Insufficient tightening may cause the bearing inner ring to rotate, wear the adjusting shims and, as a result, dangerously increase the axial play of the pinion shaft.

Check the tightness of the bearings. The preload in the bearings must be adjusted so that the moment of resistance to rotation of the drive gear shaft is in the range of 6-4 kgcm (without oil seal).

Bearings are checked using a steelyard (Fig. 7). To do this, the coupling is clamped in a vice, the steelyard is hooked to the flange hole and the gear shaft is smoothly turned.

The indication on the scale of the steelyard should be in the range of 1.25-2.9 kg (which corresponds to a torque of 6-14 kgm). In this case, the initial force that is required to bring the clutch into rotation is not taken into account.

If the resistance of the bearings to rotation is within normal limits, then the position of the nut relative to the shank should be noted by marking the end of the shaft and the nut.

After that, unscrew the nut, put the stuffing box with the cover in place and tighten the nut to the position marked with the core, and cotter it.

Install the coupling, while centering the stamped stuffing box assembly on the flange neck to ensure proper operation of the stuffing box. In this position, tighten the cover evenly with the bolts.

If no other adjustments are required, then assemble the final drive. At the same time, tighten the nuts of the differential bearings to the position marked with the marks.

Put the main gear in place and connect the flanges of the cardan yoke and the pinion shaft.

Adjusting the tightening of the backlash differential bearings and contact in the final drive gear engagement. Differential and engagement bearingse final drive gears are adjusted with adjusting nuts as follows.

Engage the drive and driven gears with a little backlash.

Tighten the adjusting nuts until they come into contact with the outer rings of the differential bearings.

Alternately tighten the bearing nuts until there is some clearance between the teeth of the driven and drive gears and some preload of the bearings is obtained.

When tightening the bearings, turn the driven gear a few turns in both directions so that the bearing rollers are in the correct position.

Loosen the bearing adjusting nuts until they are clear of the outer rings, then tighten them until they come into contact with the rings.

Adjust differential end play to zero without first tightening differential bearings.

With zero clearance and zero preload bearings, tighten the adjusting nut of each bearing one notch to preload the bearings.

Install an indicator to check the backlash of the gear teeth as shown in fig. 8.

Check the clearance at four evenly spaced points.

To increase backlash, loosen the adjusting nut on the driven gear side and tighten the nut on the drive gear shaft side by the same number of notches to keep the bearings preloaded.

To reduce the side clearance, these operations are performed in reverse order.

The rotation of the adjusting nuts is finished by tightening them.

For example, if the nut needs to be loosened by one recess, then loosen it by two, and then tighten by one recess. This ensures that the nut is in contact with the outer ring of the bearing and that the ring does not move during operation.

Gap between teeth should be 0.15-0.3 mm for different bridges, but it should not vary by more than 0.1 mm in one bridge.

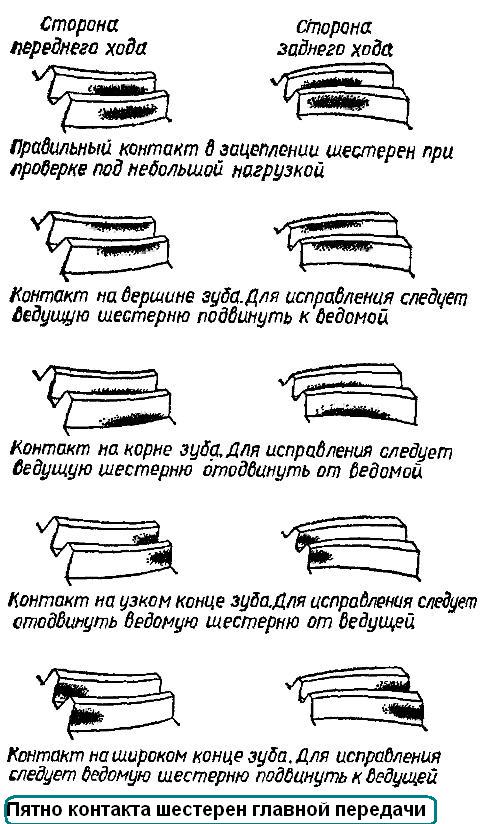

Checking gear engagement with paint. After final assembly and adjustment, the gear engagement should be checked.

For this purpose, paint the teeth with paint of the required viscosity. Very liquid paint spreads and stains the surface of the teeth, too thick is not squeezed out of the gaps between the teeth.

Slow down the drive gear shaft and rotate the driven gear in both directions until a clear contact patch is indicated

Obtaining the correct contact pattern of the teeth completes the verification of the installation of the gears and the backlash in the mesh.

Side clearance must be within the above limits. On fig. 9 shows typical contact patches on the teeth of the rear final drive gear.

If during the adjustment process it becomes necessary to move the drive gear shaft, this can be achieved by changing the thickness of the shims installed between the drive gear shaft bearing coupling flange and the end face of the gearbox housing neck.

Changing the side clearance changes the location of the contact patch.

To reduce the backlash, the driven gear is moved to the leading one. In this case, the contact patch on the working (convex) side of the tooth moves slightly below and closer to the narrow end of the tooth.

To increase backlash, the driven gear is moved away from the drive gear. In this case:

- - on the working side of the tooth, the contact spot moves slightly higher and closer to the wide end of the tooth;

- - on the non-working side of the tooth, the contact patch moves slightly higher and closer to the wide end.

When moving the drive gear to the driven gear:

- - the contact spot on the working side moves below and closer to the narrow end of the tooth;

- - the contact patch on the nonworking side moves below and closer to the wide end of the tooth.

When moving the drive gear away from the driven gear:

- - the contact spot on the working side of the tooth moves to the top of the tooth and to its wide end;

- - on the non-working side of the tooth, the contact patch moves to the top of the tooth and slightly moves towards its narrow end.