Maintenance and care of the front axle and steering rods consists of:

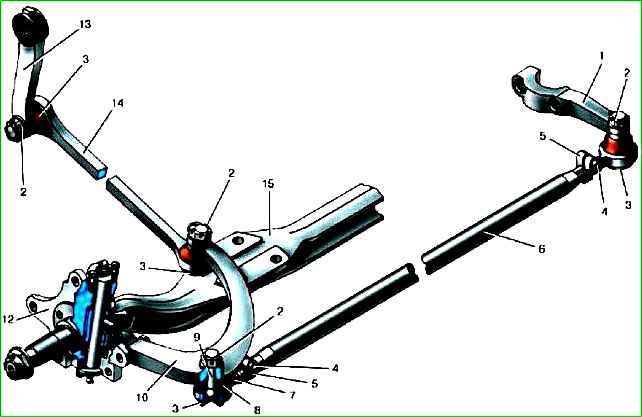

- - regularly checking the reliability of fastening and tightening the nuts of 2 tie rod pins, locking pins, pins of the tie rod tie rod bolts;

- - periodic lubrication of the pivot joint; checking play in pivot joints and steering rod joints, as well as checking wheel alignment

When checking the threaded fasteners of the front axle, observe the recommended tightening torques:

- - steering rod pins and kingpin wedge pins - at least 70 Nm (7.0 kgcm);

- - bolts of tie rod tie rods - 14-18 Nm (1.4-1.8 kgcm).

Checking the reliability of fastening of the wedge pins should be given particular importance.

When they are weakened, a backlash appears and subsequent rapid development of a hole in the beam, which necessitates repair or replacement of the beam.

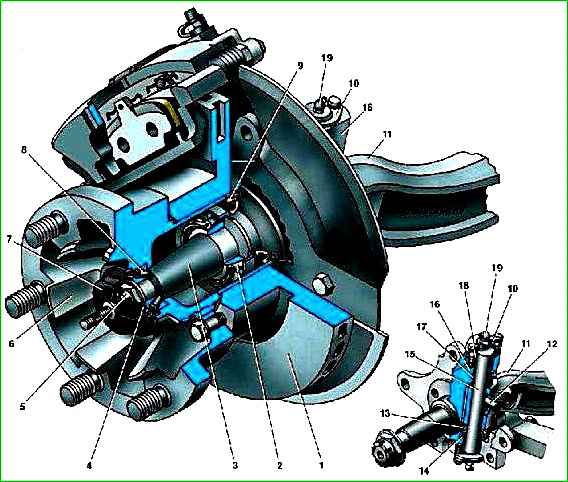

When lubrication of the pivot joint, it is necessary to ensure that the grease comes out in the upper boss of the knuckle 12 through a special slot in the beam-knuckle connector, and in the lower part - from under the edge of the thrust bearing protective cap.

If it is impossible to syringe the pivot joint with grease, it is recommended to pre-pump it with a mixture of engine oil and kerosene in a 1:1 ratio.

The play of the kingpin in the bushings is checked by rocking the wheel in a vertical plane, while the wheel should not touch the floor.

The kingpin and bushings need to be replaced if their total wear has reached 0.5 mm.

This is determined by the movement of the brake caliper body when the wheel rocks.

If the movement of the upper outer edge of the housing is more than 0.5 mm, then the pin and bushings need to be replaced.

At the same time as checking the play in the pin bushings, check the play of the steering knuckle along the axis of the pin.

It is checked with a feeler gauge placed in the gap between the upper knuckle boss 12 and the end of the beam boss 15.

A gap of more than 0.15 mm is eliminated by installing a steel shim of appropriate thickness.

Moreover, if the measured gap is more than 1 mm, the bearing needs to be replaced.

Adjusting wheel toe and camber

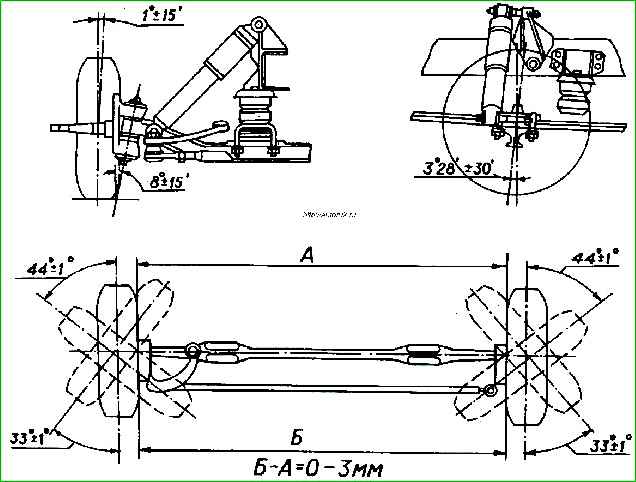

If, when the front wheels are fully turned, the normal turning radius is not ensured or the tires touch something, then check the maximum wheel rotation angle, which should be 44±1° for the inner wheel.

This angle is adjusted by changing the length of the adjusting bolts screwed into the threaded holes of the knuckle flange.

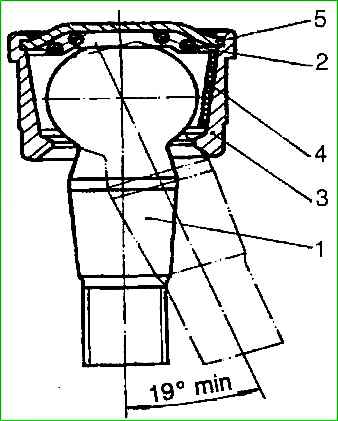

The presence of play in the steering joints is not allowed. The play in the hinges is determined by rocking the rod along the axis of pin 1.

If play is detected, the hinge must be replaced.

When checking the play in the hinges, you must carefully inspect the condition of the rubber protective caps.

Damage to them leads to rapid wear of the joint.

If damage is found, the protective cap must be replaced.

The toe angle of the wheels is determined by the difference in dimensions “A” and “B” between the inner edges of the tires.

Measurements are made in the horizontal plane tee at the level of the front wheel axle.

The difference between the indicated dimensions should be within 0-3 mm.

Adjustment of wheel toe is carried out by changing the length of the transverse steering rod.

The adjustment procedure is as follows:

- - loosen the bolts of the tie clamps 5

- - set the normal wheel toe value by rotating the tie rod pipe;

- - tighten the bolts of the coupling clamps of the tips.