Diesel model D-245.7EZ is installed on PAZ-32053-07 buses. Diesel model D-245.9EZ is installed on PAZ-4234 and PAZ-32053-07 buses

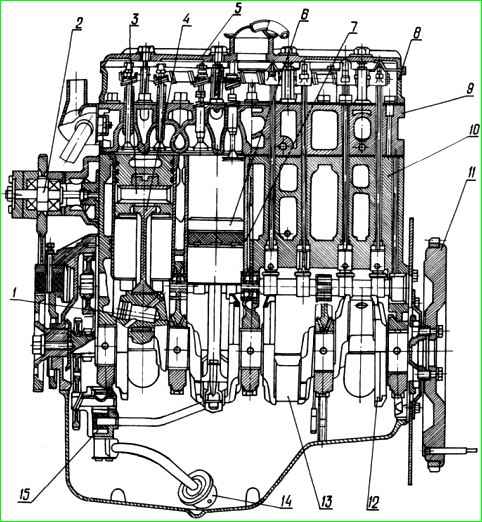

The general structure of the engine is shown in Fig. 1.

Longitudinal section of the engine: 1 - piston cooling nozzle; 2 - water pump; 3 - piston pin; 4 - connecting rod; 5 - cap; 6 - piston; 7 - cylinder liner; 8 - cylinder head cover; 9 - cylinder head; 10 - cylinder block; 11 - flywheel; 12 - crankshaft counterweight; 13 - crankshaft; 14 - oil receiver; 15 - oil pump

Diesel engines use a Common Rail fuel system with electronic injection control, which ensures environmental performance corresponding to the Euro-3 level by optimizing the work process.

The engine includes: cylinder block with suspension; crank and gas distribution mechanisms; lubrication, power and cooling systems; charging and starting devices, drives of electrical equipment and units.

Diesel technical characteristics

Engine model - D-245.7EZ or D-245.9EZ

Type Diesel, four-stroke, with turbocharging and charge air cooling.

Method of mixture formation - Direct fuel injection

Number and arrangement of cylinders 4, in-line, vertical

Cylinder displacement, l: 4.75

Cylinder operating order: 1-3-4-2

The direction of rotation of the crankshaft is right (clockwise)

Cylinder diameter/piston stroke, mm:

- D-245.7EZ - 110

- D-245.9EZ - 125

Compression ratio 17

Rated power, net, kW:

- D-245.7EZ - 85.0

- D-245.9EZ - 95.0

Rated rotation speed, min -1: 2400

Maximum torque, net, Nm:

- D-245.7EZ - 422

- D-245.9EZ - 456

Rotation speed at maximum torque, min -1:

- D-245.7EZ - 1000-1500

- D-245.9EZ - 1500-1600

Minimum idle speed, min -1: 750-800

Maximum idle speed, min -1, no more than 2650

Ventilation system - Open

Lubrication system - Combined: under pressure from the oil pump and splash

Cooling in the lubrication system - Liquid-oil heat exchanger

Oil filter - Full flow, non-separable, mod. FM 009-1012005 or M5101

High pressure fuel pump - CP3.3 (BOSCH, Germany)

Electronic diesel control unit - EDC7UC31 (BOSCH, Germany)

Nozzle - CRIN2 (BOSCH, Germany)

Coarse fuel filter - Preline PL 270 (MANN-HUMMEL GMBH, Germany)

Fine fuel filter - Mann & Hummel WDK962/12 or WDK962/14 (Germany)

Air filter - Air cleaner with paper filter elements

Supercharging system - With adjustable boost pressure and air-to-air charge air cooler

Turbocompressor - C14 (Turbo company) C15 (Turbo company) or S200G (Schwitzer company, Germany)

Diesel cooling system - Liquid, closed type, with forced circulation of liquid, thermostat and expansion tank

Engine starting aids - Glow plugs and liquid heater

Possible engine malfunctions and methods of elimination

- External manifestation of a malfunction

Remedy

Problems starting the engine

The engine does not start

1.1.1 Check that there is fuel in the fuel tank and that it is the correct grade of fuel

Fill the fuel tank

- 1.1.2 Check the functionality of the starter and its control circuits. Make the necessary repairs

- 1.1.3 Check the low pressure circuit

- - check the correct connections in the low pressure circuit

- - check for leaks in hoses and fittings

Make necessary repairs

- check the serviceability and compliance of the fuel filter

Replace the filter with the required specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Bleed the low pressure circuit

1.1.4 Check for leaks in the high pressure circuit

Make necessary repairs

1.1.5 Check the electrical circuit

- check battery charging

Make the necessary repairs or replace the battery

- check the fuses

Make necessary repairs

- check the wire for "mass"

Replace the wire with ground

1.1.6 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

1.1.7 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

1.1.8 Check the reliability of the glow plugs

Replace the glow plugs or glow plug control unit

1.1.9 Check the condition of the wiring harness (open or short)

Make necessary repairs

1.1.10 Check the compression level in the cylinders

Make necessary repairs

1.1.11 Check the injectors

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

1.1.12 Check the high pressure pump

- start the high-pressure pump test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

- - check the serviceability of the low pressure circuit;

- - check for leaks in the high pressure circuit

Make necessary repairs

1.1.13 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Engine is difficult to start or starts and then stops

1.2.1 Check that there is fuel in the fuel tank and that it is the correct grade of fuel

Fill the fuel tank

1.2.2 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- check for leaks in hoses and fittings

Make necessary repairs

- check the serviceability and compliance of the fuel filter

Replace the filter with the required specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by opening the tap

- make sure there is no air in the fuel

Bleed the low pressure circuit

1.2.3 Check for leaks in the high pressure circuit

Make necessary repairs

1.2.4 Check the electrical circuit |

- check battery charging

Make the necessary repairs or replace the battery

- check the fuses

Make necessary repairs

- check the wire for ground

Replace the wire with ground

1.2.5 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

1.2.6 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

1.2.7 Check the reliability of the glow plugs

Replace the glow plugs or glow plug control unit

1.2.8 Check the condition of the wiring harness (open or short)

Make necessary repairs

1.2.9 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

1.2.10 Check the compression level in the cylinders

Make necessary repairs

1.2.11 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

A hot engine is difficult to start

1.3.1 Check the steam meters of diesel

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

1.3.2 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace the filter with the required specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Bleed the low pressure circuit

1.3.3 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

1.3.4 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

1.3.5 Check the compression level in the cylinders

Make necessary repairs

1.3.6 Check the condition of the wiring harness (broken or pinched)

Make necessary repairs

1.3.7 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Unstable engine idling

Unstable idle speed

2.1.1 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace the filter with the required specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Bleed the low pressure circuit

2.1.2 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

2.1.3 Check the condition of the wiring harness (open or short)

Make necessary repairs

2.1.4 Check for leaks in the high pressure circuit

Make necessary repairs

2.1.5 Check the compression level in the cylinders

Make necessary repairs

2.1.6 Check the injectors

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

2.1.7 Check the high pressure pump

- start the high-pressure pump test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- - check the serviceability of the low pressure circuit;

- - check for leaks in the high pressure circuit

Make necessary repairs

Idle speed too high or too low

2.2.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- use a diagnostic tool to check the status of the electricity consumers of the CRS system

Carry out diagnostics and necessary repairs

2.2.2 Check the electrical circuit

- check battery charging

Repair or replace A

- check the fuses

Produce necessary repairs

- check the wire for ground

Replace the wire with ground

2.2.3 Check that the clutch is adjusted correctly

Make necessary repairs

2.2.4 Check the condition of the wiring harness (open or short)

Make necessary repairs

2.2.5 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Engine behavior when the vehicle is moving

Unstable engine operation during acceleration/deceleration

3.1.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- use a diagnostic tool to check the status of the electricity consumers of the CRS system

Carry out diagnostics and necessary repairs

3.1.2 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter

- check that the intake manifold is not clogged

Clean the intake manifold

3.1.3 Check the condition of the wiring harness (open or short)

Make necessary repairs

3.1.4 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

3.1.5 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

- 3.2 Dips during acceleration and when engaging the clutch

- 3.2.1 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter

- check that the intake manifold is not clogged

Clean the intake manifold

3.2.2 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- use a diagnostic tool to check the status of the electricity consumers of the CRS system

Perform diagnostics and repairs

- 3.2.3 Determine the health status of the turbocharger

- 3.2.4 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by opening the tap

- make sure there is no air in the fuel

Remove air

3.2.5 Check the compression level in the cylinders

Make necessary repairs

3.2.6 Check for leaks in the high pressure circuit

Make necessary repairs

3.2.7 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

3.2.8 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Stopping the engine

3.3.1 Check for fuel in the fuel tank

Fill the fuel tank

3.3.2 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Remove air

3.3.3 Check for leaks in the high pressure circuit

Make necessary repairs

3.3.4 Check the electrical circuit

- check battery charging

Repair or replace the battery

- check the fuses

Make necessary repairs

- check the wire for ground

Replace the wire d to ground

3.3.5 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

3.3.6 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

3.3.7 Check the condition of the wiring harness (broken or pinched)

Make necessary repairs

3.3.8 Check the high pressure pump

- start the high-pressure pump test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- - check the serviceability of the low pressure circuit;

- - check for leaks in the high pressure circuit

Make necessary repairs

3.3.9 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

The engine runs intermittently

3.4.1 Check for fuel in the fuel tank

Fill the fuel tank

3.4.2 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Remove air

3.4.3 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Perform diagnostics and repairs

3.4.4 Check the condition of the wiring harness (open or short)

Make necessary repairs

3.4.5 Check the compression level in the cylinders

Make necessary repairs

3.4.6 Check the clearances in the valve drive

Adjust the clearances in the valve drive

3.4.7 Check the high pressure pump

- start the high-pressure pump test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- - check the serviceability of the low pressure circuit;

- - check for leaks in the high pressure circuit

Make necessary repairs

3.4.8 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Insufficient power

3.5.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard test program “KTS - Bosch”

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

3.5.2 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

3.5.3 Check the engine oil level

Fill with oil

- 3.5.4 Determine the health status of the turbocharger

- 3.5.5 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water, open Turning the tap

- make sure there is no air in the fuel

Remove air

3.5.6 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

3.5.7 Check the compression level in the cylinders

Make necessary repairs

3.5.8 Check the clearances in the valve drive

Adjust the clearances in the valve drive

Excessive power

3.6.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

3.6.2 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

3.6.3 Check oil consumption (engine overload)

If oil consumption is increased, make the necessary repairs

3.6.4 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

3.6.5 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Excessive fuel consumption

3.7.1 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by opening the tap

- make sure there is no air in the fuel

Remove air

3.7.2 There are leaks in the diesel fuel temperature sensor

Replace the fuel temperature sensor

3.7.3 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

3.7.4 Check for leaks in the high pressure circuit

Make necessary repairs

3.7.5 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

3.7.6 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

3.7.7 Check the engine oil level

Fill with oil to the level

- 3.7.8 Determine the serviceability status of the turbocharger

- 3.7.9 Check the compression level in the cylinders

Make necessary repairs

3.7.10 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Extra-high engine speeds when releasing the pedal or changing gear

3.8.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

3.8.2 Check the condition of the wiring harness (open or short)

Make necessary repairs

3.8.3 Check that the clutch is adjusted correctly

Make necessary repairs

- 3.8.4 Determine the serviceability status of the turbocharger

- 3.8.5 Execute checking injectors

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

3.8.6 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

The engine stalls when accelerating

3.9.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out a standard test

test program “KTS - Bosch”

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

3.9.2 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

3.9.3 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Remove air

3.9.4 Check that the clutch is adjusted correctly

Make necessary repairs

3.9.5 Check the condition of the wiring harness (open or short)

Make necessary repairs

3.9.6 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

The engine does not stop

3.10.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

Noise, smell or smoke

Knocking or noise in the engine

4.1.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Repair in a special workshop)

- use a diagnostic tool to check the status of the electricity consumers of the CRS system

Carry out diagnostics and necessary repairs

4.1.2 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

4.1.3 Check the compression level in the cylinders

Make necessary repairs

4.1.4 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by opening the tap

- make sure there is no air in the fuel

Remove air

4.1.5 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

Intermittent noise

4.2.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device.

(Testing and repair in a specialized workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

4.2.2 Check the condition of the wiring harness (broken or pinched)

Produce necessary repairs

4.2.3 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Various mechanical noises

4.3.1 Make sure that the injectors do not rattle (unloading through the injectors)

Make necessary repairs

4.3.2 Fuel pipe holders are broken or missing

Make necessary repairs

4.3.3 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

4.3.4 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

4.3.5 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

4.3.6 Check that the clutch is adjusted correctly

Make necessary repairs

- 4.3.7 Determine the serviceability of the turbocharger

- 4.3.8 Check the clearances in the valve drive

Adjust the clearances in the valve drive

Exhaust gas smell

4.4.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

4.4.2 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter

- check that the intake manifold is not clogged

Clean the intake manifold

4.4.3 Check oil consumption (engine overload)

If oil consumption is increased, carry out the necessary repairs

- 4.4.4 Determine the serviceability status of the turbocharger

- 4.4.5 Check the engine oil level

Fill with oil to the required level

4.4.6 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

4.4.7 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Smell of diesel fuel

4.5.1 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Remove air

4.5.2 There are leaks in the diesel fuel temperature sensor

Replace the fuel temperature sensor or rubber o-ring

4.5.3 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS-Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

4.5.4 Check for leaks in the high pressure circuit

Make necessary repairs

Blue, white or black smoke

4.6.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard “KTS - Bosch” test program

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

4.6.2 Check the intake system

- check for leaks/air leaks

Produce necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

4.6.3 Check the engine oil level

Bring the oil filling level to the top of the oil gauge mark

4.6.4 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Remove air

4.6.5 Check oil consumption (engine overload)

If oil consumption is increased, make the necessary repairs

4.6.6 Check the compression level in the cylinders

Make necessary repairs

4.6.7 Perform an injector check

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

Blue, white or black smoke when accelerating

4.7.1 Check diesel parameters

- use a diagnostic tool to check for faults in the COMMON RAIL injection system, carry out the standard test program “KTS - Boschn

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

- check the condition of electricity consumers using a diagnostic tool

Carry out diagnostics and necessary repairs

4.7.2 Check the intake system

- check for leaks/air leaks

Make necessary repairs

- check the condition of the air filter

Replace the air filter with a new one

- check that the intake manifold is not clogged

Clean the intake manifold

4.7.3 Check the low pressure circuit

- check the correct connections in the low pressure circuit

Make necessary repairs

- - check for leaks in hoses and fittings

- - check the serviceability and compliance of the fuel filter

Replace filter to specification

- make sure there is no water in the diesel fuel in the glass on the fuel coarse filter

Clean the fuel filter from water by draining it by opening the tap

- make sure there is no air in the fuel

Bleed the low pressure circuit

4.7.4 Check the engine oil level

Bring the oil filling level to the upper mark of the oil gauge

- 4.7.5 Determine the serviceability status of the turbocharger

- 4.7.6 Check oil consumption (engine overload)

If oil consumption is increased, make the necessary repairs

4.7.7 Check the compression level in the cylinders

Make necessary repairs

4.7.8 Check for leaks in the high pressure circuit

Make necessary repairs

4.7.9 Check the condition of the wiring harness (broken or pinched)

Make necessary repairs

4.7.10 Check the injectors

- start the injector test cycle with the corresponding command of the standard test program of the KTS - Bosch diagnostic device

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

4.7.11 Checking the control unit

- check the reliability of the control unit connectors

Secure the connectors

Diesel overheats

5.1 Insufficient amount of coolant in the cooling system

Add coolant to the radiator to the normal level

5.2 The outside of the radiator is dirty

Clean the radiator

5.3 The thermostat valve does not open completely

Replace the thermostat

5.4 Insufficient fan belt tension

Tighten the belt

5.5 Oiling the fan drive belt and pulleys

Remove the drive belt, remove oil from the surface of the belt and pulley

Oil pressure on a heated diesel engine is below the permissible level

6.1.1 Using a diagnostic tool, check for faults in the COMMON RAIL injection system, carry out the standard KTS - Bosch test program

Follow the instructions in the diagnostic program of the KTS - Bosch device

(Repair in a special workshop)

6.1.2 Faulty sensor or pressure indicator (duplicate devices)

Replace the pressure sensor or indicator, if necessary, measure the pressure with a control device

6.2 The tightness of the oil pipe connections is broken

Identify the location of the violation tightness and restore it

6.3 Oil pump faulty

Identify the problem and fix it

6.4 The oil level in the diesel crankcase is below the permissible level

Add oil to the upper mark of the oil gauge

6.5 Limit wear in the joints: crankshaft journals - main (connecting rod) bearings

Fix the problem

6.6 The safety valve in the oil filter housing is jammed

Wash the valve and valve channel in the filter housing.

Adjust the pressure in the lubrication system

6.7 Oil filter clogged

Replace the oil filter

Turbocharger

- 7.1 The turbocharger rotor does not rotate (there is no characteristic high-pitched sound)

- 7.1.1 Presence of foreign objects preventing rotor rotation

Remove the inlet and outlet pipes, remove foreign objects

7.1.2 Jamming of the rotor in the bearing

Replace the turbocharger

7.2.Increased oil emissions from the compressor or turbine side, violation of the tightness of the turbocharger oil seals

Remove the turbocharger from the diesel engine and send it for repair

Starter

When the starter is turned on, the diesel crankshaft does not turn or rotates very slowly

8.1.1 Loose battery terminals or oxidation of wire tips

Strip the tips and tighten the terminals

8.1.2 Battery is low

Charge or replace the battery

8.1.3 The commutator and brushes are dirty

Clean the commutator and brushes

8.1.4 Poor contact of brushes with commutator. Brush wear

Remove the starter from the diesel engine, clean the commutator, eliminate stuck brushes or replace them if they are worn

8.1.5 The surfaces of the contact bolts and contact plate in the starter relay that are in contact when turned on are burnt

Clean the contacts of the starter relay or install the contact bolts in the cover sockets, turning them around the axis by 180°, and install the contact plate with the reverse side

8.1.6 The starter drive is faulty

Replace the starter drive

8.2 After starting the diesel engine, the starter remains in the on state

8.2.1 The contact plate is welded to the starter contact relay bolts or the contacts in the starter control circuit relay are welded

Stop the diesel engine, disconnect the battery and perform the work according to paragraph 8.1.5 or replace the relay in the starter control circuit

The starter armature rotates at high speed without turning the diesel crankshaft

8.3.1 Fractured flywheel ring teeth

Replace the flywheel crown

8.3.2 The starter drive is faulty

Replace the starter drive

- 8.4 The starter relay works intermittently (turns on the starter and immediately turns off)

- 8.4.1 Break in the relay holding winding

Replace the relay

8.4.2 Battery is low

Charge or replace the battery

- 8.5 The drive gear does not systematically engage with the flywheel ring during normal relay operation

- 8.5.1 End wear of flywheel gear

Replace the flywheel crown

8.5.2 Jamming of the drive gear on the armature shaft due to lack of or poor quality lubrication

Clean the drive and shaft from old grease; apply lubricant CIATIM-201/203/221

8.5.3 End wear of part of the drive gear teeth

Replace the drive

Generator

The voltmeter does not show charging after starting the diesel engine and then during the entire operating time

9.1.1 Breakage of the positive terminal or short circuit to the generator housing;

Disconnect the rectifier, solder and isolate the break point. Isolate the area where the insulation is damaged. (Repair in a specialized workshop)

9.1.2 Open circuit of the excitation coil

Disassemble the generator, solder and insulate the damaged area, or replace the excitation coil. (Repair in a specialized workshop)

9.1.3 Short circuit to the generator housing of one of the stator phases

Replace the stator. Repair in a special workshop

9.1.4 Short circuit of power rectifier terminals or breakdown of diodes of direct and reverse polarity

Replace the rectifier device. (Repair in a specialized workshop)

9.1.5 Voltage regulator is faulty

Replace the voltage regulator. (Repair in a specialized workshop)

9.1.6 Poor contact of brushes with the commutator, stuck or worn brushes

Clean the commutator, fix sticking or replace brushes

The generator is not delivering full power

9.2.1 Broken wires going to the regulator

Solder and insulate the damaged area (Repair in a specialized workshop)

9.2.2 Breakage of one of the stator phases

Replace the stator. Repair in a special workshop

9.2.3 Interturn short circuit of the stator winding

Replace the stator. Repair in a special workshop

9.2.4 Interturn short circuit of the field coil winding

Replace the excitation coil (Repair in a specialized workshop)

9.2.5 Faulty one of the power rectifier diodes

Replace the rectifier device (Repair at a specialized workshop)

The battery is systematically recharged

9.3.1 Voltage regulator is faulty

Replace the voltage regulator (Repair at a specialist workshop)

9.3.2 Short circuit to the housing of the voltage regulator terminal “Ш”

Isolate the area where the insulation is damaged (Repair at a specialist workshop)

Generator noise

9.4.1 Belt slippage or excessive tension

Adjust the belt tension