VAZ cars. Adjustment of the front door locks (VAZ-2108, -2109 cars) is carried out by changing the position of the lock, which can be adjusted due to enlarged holes in the pillar

Before making adjustments, it is recommended to outline the contours of the clamp on the stand.

If the door closes too tightly, loosen the screws securing the latch, move it outward and tighten the screws. If the door closes poorly, the latch is moved inward.

In this case, the door should not protrude or recess relative to the body.

If the door goes down when closing, the latch is raised.

If the door lifts when closing (sagging in the open position), the latch is lowered.

To ensure that the adjustment of the clamp is not disturbed, a gasket made of waterproof sandpaper is installed under it.

The spacers under the lock adjust the distance of the lock from the stand so that the pin of the lock does not touch the cover of the external lock

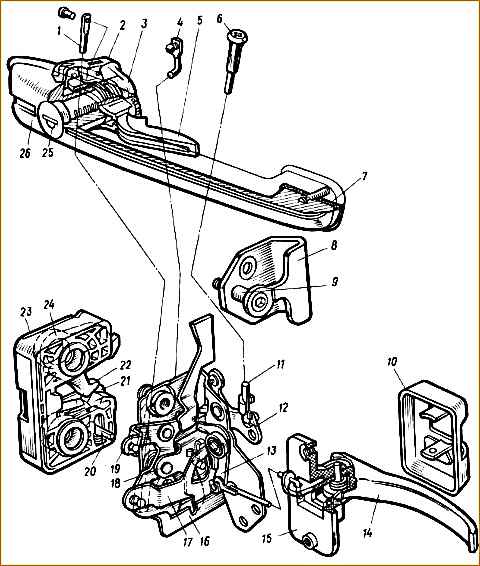

Front right door lock: 1 - external drive lever rod; 2 - key guide; 3 - lock switch lever; 4 - switch rod; 5 - key; 6 - lock release button; 7 - sealing gasket of the outer handle; 8 - lock body; 9 - locking pin; 10 - lining of the inner handle; 11 - shutdown button rod; 12.19 - shutdown levers; 13 - internal drive lever; 14, 26 - internal and external door handles, respectively; 15 - bracket for the internal handle; 16 - internal lock body; 17 - lever of external lock drive; 18 - intermediate lever; 20 - lock drive finger; 21 - dog; 22 - clamp; 23 - external lock cover; 24 - external lock body; 25 - lock switch

The position of the inner lock handle is adjusted by moving its bracket using oval holes on the inner door panel for fastening screws.

If the door does not open well with the inside handle, then loosen the screws securing the handle bracket and move the handle together with the bracket to the desired position and tighten the screws.

The tailgate lock of VAZ-2108, -2109 cars is also adjusted by changing the position of the latch, which has enlarged holes for the fastening screws.

Adjustment of the door position is achieved due to enlarged holes in the hinges for their fastening bolts.

The gaps between the doors and the body must be the same.

When adjusting, loosen the hinge fastening bolts, set the gaps taking into account the settlement of the door after loading it, and tighten the bolts.

To determine the amount of displacement of the hinges, you must first outline their contours on the front pillar.

To check the settlement, the load is applied to the door, slightly open at an angle of 5 °, with a uniform increase from 0 to

The design of the window lifter at the doors eliminates its adjustment.

During operation, you only need to check the fastening of parts.

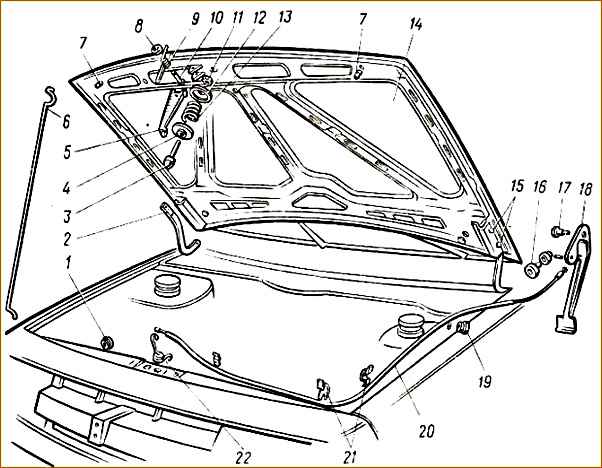

Hood and lock parts: 1 - hood stop bushing; 2 - hood hinge; 3 - pin; 4 - lower cup; 5 - hook; 6 - emphasis; 7 - buffers; 8 - lock washer; 9 - hook spring; 10 - hook axis; 11 - lock nut; 12 - upper cup; 13 - pin spring; 14 - hood; 15 - hood mounting bolts; 16 - rod shell bushing; 17 - handle axis; 18 - lock handle; 19 - lock rod seal; 20 - shell with lock rod; 21 - lock rod holder; 22 - lock spring

Adjustment of the hood in relation to the front surfaces of the front wings and the radiator lining is carried out by changing the height of pin 3

Using pin 3 and spring 22, hood 14 is fixed in the closed position.

The pin is wrapped in the hood and locked with locknut 11.

Cups 4 and 12 with a spring between them are installed on the pin.

Increasing the hole in the brackets for attaching the hinges to the hood allows for adjustment of the position of the hood in the body opening.

When adjusting, loosen the bolts 15 securing the hinges, move the hood so that the gaps between it and the wings are equal, and tighten the bolts.

If the hood is not locked securely with the lock, loosen the locknut 11 securing pin 3 and displace it due to the enlarged hole in the hood, achieving alignment with the lock socket, then tighten the locknut

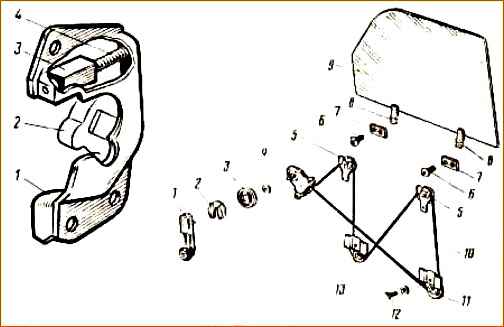

For VAZ-2101, -21011, -2102, -2104, -2105, -2106, -2107, adjustment of door locks (both rear and front) is carried out due to enlarged holes for the bolts securing the lock retainer 1.</p >

The sequence of adjusting the door lock of these car models, despite the difference in the design of the clamps, is similar to the VAZ-2108 model.

If the door is difficult to unlock with the inside handle, its position is adjusted by loosening the screws securing the handle bracket and moving the handle together with the bracket to the desired position and tightening the screws.

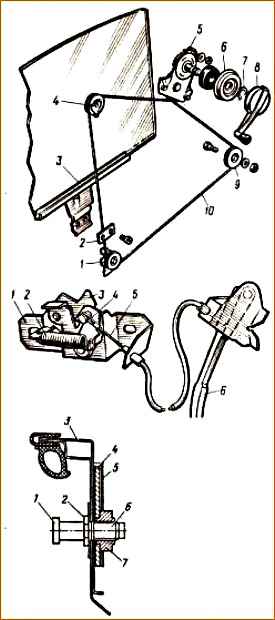

The amount of free play of the sliding glass of the front doors of the VAZ-2105, -2104, -2107 models is adjusted by lowering the glass all the way into the rubber buffer, and handle 1, with the screws 6 of the pressure plates turned out, is turned until the bushing on the front vertical branch of the cable is aligned with the middle of the front bracket 8 and tighten screws 6.

Using tension roller 13, the smooth operation of the window lift is adjusted, after which the tension roller bolt nut is finally tightened.

For VAZ-2101, -21011, -2102, -2106 cars, the window lifter is adjusted with the screws of the pressure plate 2 loosened and the glass lowered all the way.

The window lifter handle 8 is turned all the way in the direction of lowering the glass, then returned half a turn.

In this position of the glass and the cable, the cable is secured in the cage.

The smooth operation of the window lifter is regulated by the tension of the drive cable by moving the tension roller 9. The rear door window lifters are adjusted in the same way.

The hood lock of the VAZ-2101, -21011, -2102, -2104, -2105, -2106, -2107 models is mounted on the air intake box, the lock pin is welded to the reinforcement of the inner hood panel.

The holes in the housing / for fastening are oval and allow you to adjust the position of the lock.

When closing, the hood pin presses the ejector 3 and the hook 4, which, under the action of the spring 2, grabs the pin.

If the hood lock does not close or closes with difficulty, then with the hood open, outline the contours of the lock body 1 and, using the oval holes, move the lock body in the desired direction.

Tighten the fastening nuts and check the operation of the lock. The hood in the body opening should be located with a gap around the perimeter (4.5 ± 2.0) mm.

When adjusting, the contours of the loops are outlined and their fastening is loosened. By enlarging the holes in the hinges, adjust the position of the hood and tighten the hinge bolts.

The position of the trunk lid of the VAZ-2101, -21011, -2105, -2106, -2107 models is adjusted, as is the position of the hood, by loosening the hinge fastening nuts.

The average gap size should be (5 ± 2) mm.

To adjust the hood lock, outline the contours of the lock and latch, loosen their fastening and move them to a new position.

Tighten the bolts slightly, check the operation and finally secure the lock and latch.

The trunk lid hinges have a torsion mechanism that makes opening the lid easier.

Regulation of the lid opening force is carried out by rearranging the ends of the torsion bars to one of the fixing teeth of the hinge.

Adjustment of the position of the lock and tailgate of the VAZ-2104 car is also carried out by moving the door at the hinge fastening points and by changing the position of the lock and latch.