The transmission of the Lada 21902 car includes an automatic gearbox equipped with a torque converter and front wheel drive

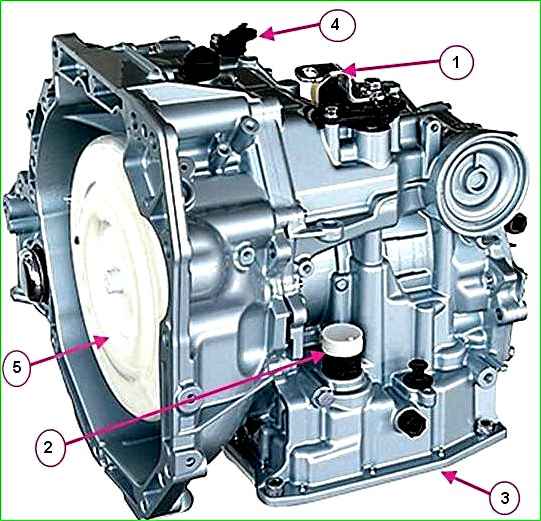

The car is equipped with a four-speed automatic transmission JATCO AY-K3, made according to a two-shaft design and combined with a differential and final drive.

A three-element, single-stage, two-phase torque converter is installed on the automatic transmission.

The torque converter has a locking clutch, which eliminates the discrepancy between the engine speed and the input shaft.

The torque converter locking mode is provided when driving in third and fourth gear, the lever is in the “D” position.

Automatic transmission control controller

The automatic transmission control controller is located on the left mudguard.

Control is carried out based on signals coming from sensors, switches and other control devices.

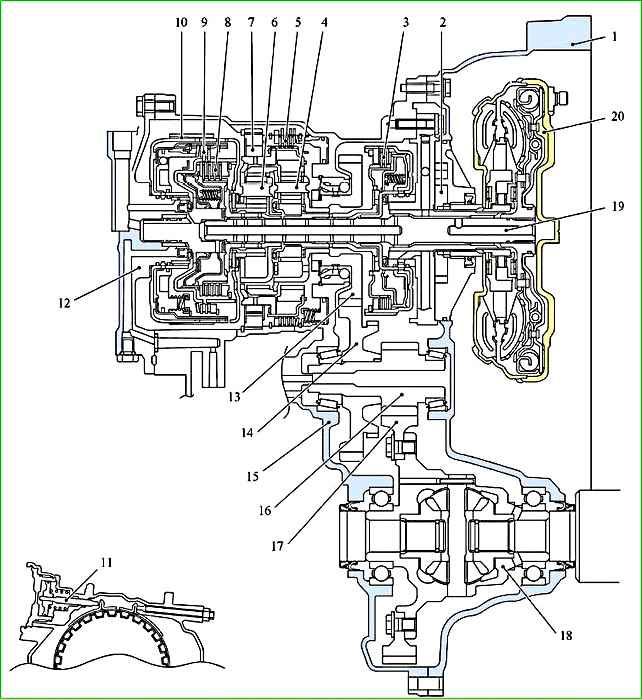

Torque converter

The torque converter converts torque from the engine and transmits it to the input shaft of the gearbox.

Oil pump

The oil pump is driven by the engine and transmits it to the input shaft of the gearbox

The control valve block consists of the following parts:

- - transmission fluid temperature sensor;

- - input shaft speed sensor;

- - downshift clutch solenoid valve;

- - brake solenoid valve 2-4 gears;

- - gear shift solenoid valve;

- - solenoid valve for overdrive clutch/downshift brake and reverse gear;

- - solenoid valve of the torque converter lock-up clutch;

- - solenoid valve for regulating pressure in the line;

- - assembled ROM module (EEPROM).

ROM assembly (ROM)

The ROM module assembly is located in the control valve block.

The ROM module stores the calibration data (individual values) of each linear solenoid valve.

Upon receiving calibration data, the automatic transmission control controller carries out precise hydraulic adjustment.

Gearbox range switch

The gearbox range switch is located at the top of the gearbox housing.

The transmission range switch determines the position of the gear selector lever.

Input shaft speed sensor

The input shaft speed sensor is located in the control valve block.

The input shaft speed sensor determines the speed of rotation of the input shaft.

The sensor generates on-off pulse signals in accordance with the rotor speed.

The automatic transmission control controller estimates the rotation speed using a pulse signal.

Secondary shaft speed sensor (vehicle speed sensor)

The secondary shaft speed sensor is installed in the upper part of the gearbox housing.

The secondary shaft speed sensor determines the speed of rotation of the secondary shaft by the number of revolutions of the idler gear.

The sensor generates on-off pulse signals in accordance with the speed of the idler gear rotor.

The automatic transmission control controller estimates the rotation speed using a pulse signal.

The automatic transmission control controller determines the vehicle speed based on the signal from the secondary shaft speed sensor.

Transmission fluid temperature sensor (TFTF)

The transmission fluid temperature sensor is located in the control valve block.

The transmission fluid temperature sensor detects the temperature of the transmission fluid in the oil pan.

A thermistor is used as a transmission fluid temperature sensor.

The output voltage of the thermistor signal depends on the temperature of the transmission fluid.

The automatic transmission control controller determines the temperature of the transmission fluid based on the voltage of the DTZH signal.

Underdrive clutch solenoid valve

The downshift clutch solenoid valve is located in the control valve block.

The reduction clutch solenoid valve controls the pressure in the reduction clutch.

A linear solenoid valve of the normally open type is used as the downshift clutch solenoid valve.

The linear solenoid valve uses the principle that the clamping force of the solenoid core varies in direct proportion to the electric current.

A normally open valve creates high fluid pressure on the actuator if power is not supplied to the valve.

Brake solenoid valve 2-4 gears

The 2nd-4th gear brake solenoid valve is installed in the control valve block.

The 2nd-4th gear brake solenoid valve controls the pressure of the 2nd-4th gear brake band.

A linear solenoid valve of the normally closed type is used as the 2nd-4th gear brake solenoid valve.

The linear solenoid valve uses the principle that the clamping force of the solenoid core varies in direct proportion to the electric current.

A normally closed valve creates high fluid pressure on the actuator when power is supplied to the valve.

On-off solenoid valve

The on/off solenoid valve is located in the control valve block.

The on-off solenoid valve operates the shift valve, which switches the flow of oil to the downshift and reverse brakes and the overdrive clutch.

A normally closed type solenoid valve is used as an on/off solenoid valve.

Solenoid valve for overdrive clutch and downshift and reverse brake

The solenoid valve for the overdrive clutch and the downshift and reverse brake clutch is located in the control valve block.

The overdrive clutch solenoid valve regulates the pressure in the overdrive clutch and the downshift and reverse brake.

A normally open type linear solenoid valve is used as the solenoid valve for the overdrive clutch and downshift and reverse brake.

Torque converter lockup clutch solenoid valve

The torque converter lockup clutch solenoid valve is located in the control valve block.

The torque converter lockup clutch solenoid valve controls the torque converter lockup clutch control valve.

A linear solenoid valve of the normally closed type is used as the solenoid valve for the torque converter lock-up clutch.

Electromagnetic valve for regulating pressure in the line

The solenoid valve for regulating the pressure in the line is located in the control valve block.

The line pressure control solenoid valve controls the operation of the line pressure control valve.

A linear solenoid valve of the normally open type is used as a solenoid valve for regulating pressure in the line.

Technical characteristics of automatic transmission 21902-1700010

Engine - VAZ-21126

Torque converter - three-element, single-stage, two-phase;

Torque transformation coefficient with a stationary turbine wheel - 1.91;

Gear selector positions:

- R - reverse;

- N - neutral position (engine starting is possible);

- D - forward movement: 1↔2↔3↔4;

- 2 - 1↔2←3←4;

- 1 - 1←2

Gear ratio:

- 1GR - 2,861;

- 2GR - 1,562;

- 3GR - 1,000;

- 4GR - 0.697;

- reverse - 2,310

Mainstream gear ratio food - 4,081;

Control system - electric;

Function:

- Displacement adjustment - equipped;

- Line pressure regulation - equipped;

- Gear shift control - equipped;

- Lock control - equipped;

- Self-diagnosis - equipped;

- Preservation of operability in case of failure of individual elements - equipped

Internal gear oil pump "parachoid", engine driven

Transmission fluid - NISSAN ATF MAT1C-S (quantity 5.1 liters, controlled using a level indicator)