In this article we will consider the pneumatic drive of trailer brakes, i.e. the interaction and malfunctions of devices installed on the tractor and on the trailer

First, let's consider the option of connecting the brake systems of the tractor and. trailer via two-wire drive.

If the trailer tank does not fill with air, first check that the supply and control lines are connected correctly.

Let's look at malfunctions due to which there is no air supply to the sight cylinder, and ways to detect these malfunctions.

After disconnecting the connecting heads in the supply line and opening the disconnect valve, no air flows from the connecting head to the tractor

By connecting a pressure gauge to the control valve on the parking brake cylinder, check the air pressure in the cylinder.

If the pressure in the cylinder is less than 5.4-5.6 kgf/cm 2, the single safety valve does not allow air into the supply line - you need to find out the reason why the pressure does not rise above the specified value. p>

Even if the pressure in the cylinder is more than 5.6 kgf/cm 2, blockage of the air lines, incorrect adjustment or malfunction of the single safety valve, or malfunction of the isolation valve are possible.

When the isolation valve is open air flows from the connecting head into the supply line of the tractor, but after connecting the heads of the tractor and trailer, air does not flow to the supply inlet of the air distributor

The reason for this is blockage of the air ducts or severe pollution, and in winter, icing of the main filter.

If air is supplied to the air distributor, but does not enter the cylinder, the air distributor is faulty or the air line from the device to the cylinder is clogged.

When braking a road train the brakes on the tractor are activated, but not on the trailer.

Disconnect the Palm heads of the control line, open the disconnect valve, press the brake pedal.

If compressed air does not come out of the head, then the trailer brake control valve with a two-wire drive is faulty.

It is also possible that the lines from the parking brake cylinders to the trailer brake control valve or from the valve outlet to the disconnect valve and the connecting head of the control line are clogged.

If air comes out of the Palm head of the tractor control line when braking, then the drive on the trailer is faulty, the pipelines do not allow air to pass through, the line filter is clogged or iced up, the air distributor, solenoid valve or brake force regulator is faulty .

More accurately, faults can be determined by sequentially disconnecting pipelines and devices.

First, the control line from the connecting head to the air distributor is checked, and then the supply line from the air distributor to the brake chambers.

When the road train is released the wheels of the tractor are released, and the trailer remains in a braked state

Close the isolation valve in the control line, if after this the air from the line escapes into the atmosphere through the atmospheric outlet of the valve, and the trailer releases the brakes, then the trailer brake control valve with a two-wire drive is faulty.

The valve does not release air into the atmosphere when released due to the jamming of the upper piston or the piston rod in the middle part of the device.

If, when closing the isolation valve, air is not released into the atmosphere through the valve, since it has already escaped into the atmosphere through the trailer brake control valve, the air distributor, solenoid valve or brake force regulator is faulty.

When braking with the service or parking brake air escapes from the atmospheric outlet of the trailer brake control valve with a two-wire drive

In this case, the sealing rings or the valve in the device itself are leaking.

After releasing the brake, air continues to escape from the atmospheric outlet of the two-wire valve.

Faults are possible in the device itself (valve sleeve seals), in the single-drive trailer brake control valve (rod seals in the piston or piston in the guide), in the air distributor (upper piston pusher seal).

To find the faulty device, disconnect the Palm heads of the control line; if the air leakage from the two-wire valve has stopped, but is observed from the trailer head, then the air distributor is faulty.

If a faulty device is not found at this stage of the test, close the isolation valve in the control line and disconnect the control line at the two-wire valve.

Leaking from the atmospheric terminal of the two-wire valve continues, which means it is faulty.

Air has begun to leak from the disconnected line —► the trailer brake control valve with a single-line drive is faulty.

If there is a leak in air flows from the atmospheric outlet of the air distributor when braking, the device itself is faulty (the exhaust valve is leaking).

If air leaks from the atmospheric outlet of the air distributor after the brake is released, the malfunction may be in the device itself or in the solenoid valve.

You can detect a faulty device by disconnecting the line between the air distributor and the solenoid valve, if the leak through the air distributor continues - the air distributor is faulty, it started from the disconnected line - the solenoid valve.

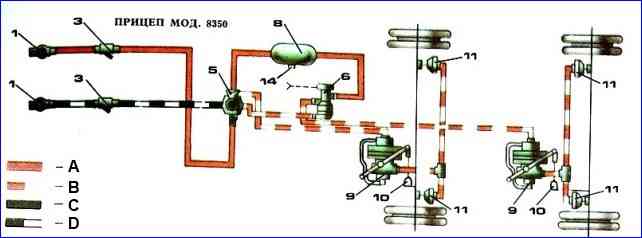

Trailer model 8350: 1 – Palm type connecting head; 2 – connection head type “B”; 3 – main filter; 4 – two-line valve with pressure limitation; 5 – combined air distributor; 6 – solenoid valve; 7 – single safety valve; 8 – receiver; 9 – automatic brake force regulator; 10 – elastic element; 11 – brake chamber; 12 – control valve; 13 – tap for inflating tires; 14 – condensate drain valve; A – supply line; B – control line; C – connecting line; D – control line

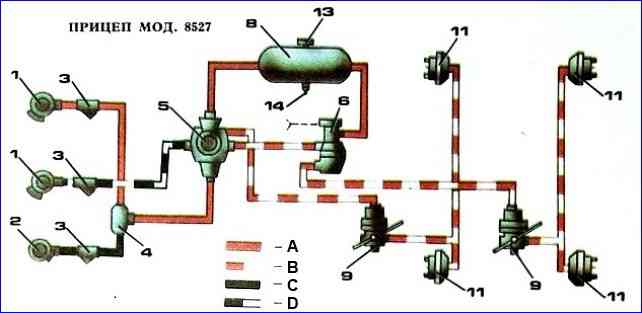

Trailer model 8527: 1 – Palm type connecting head; 2 – connection head type “B”; 3 – main filter; 4 – two-line valve with pressure limitation; 5 – combined air distributor; 6 – solenoid valve; 7 – single safety valve; 8 – receiver; 9 – automatic brake force regulator; 10 – elastic element; 11 – brake chamber; 12 – control valve; 13 – tap for inflating tires; 14 – condensate drain valve; A – supply line; B – control line; C – connecting line; D – control line

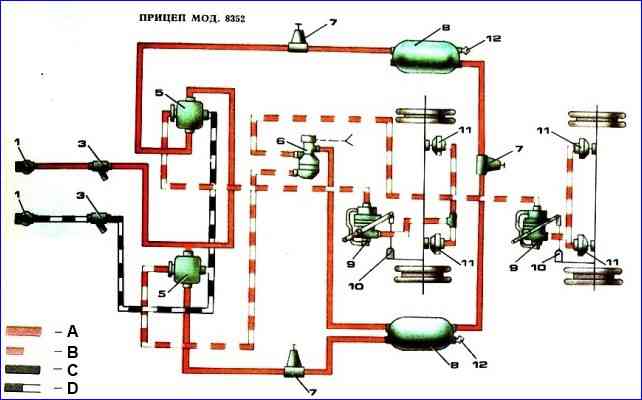

Trailer model 8352: 1 – Palm type connecting head; 2 – connection head type “B”; 3 – main filter; 4 – two-line valve with pressure limitation; 5 – combined air distributor; 6 – solenoid valve; 7 – single safety valve; 8 – receiver; 9 – automatic brake force regulator; 10 – elastic element; 11 – brake chamber; 12 – control valve; 13 – tap for inflating tires; 14 – condensate drain valve; A – supply line; B – control line; C – connecting line; D – control line

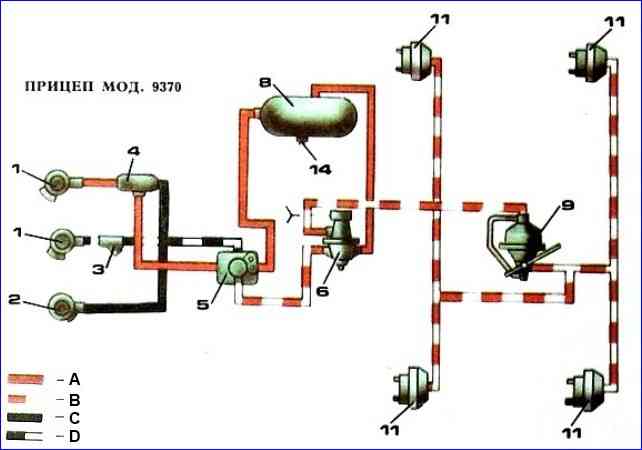

Trailer model 9370: 1 – Palm type connecting head; 2 – connection head type “B”; 3 – main filter; 4 – two-line valve with pressure limitation; 5 – combined air distributor; 6 – solenoid valve; 7 – single safety valve; 8 – receiver; 9 – automatic brake force regulator; 10 – elastic element; 11 – brake chamber; 12 – control valve; 13 – tap for inflating tires; 14 – condensate drain valve; A – supply line; B – control line; C – connecting line; D – control line

Malfunctions that occur when controlling trailer brakes using a single-wire drive

The road train is released and air is not supplied to the trailer cylinder

The cause may be a malfunction or incorrect adjustment of the single safety valve, blockage of the pipelines through which air is supplied to the single-line trailer brake control valve, a malfunction of this valve or a malfunction of the isolation valve.

You should also keep in mind the following: if the trailer brake control valve with a two-line drive does not bleed air from the control line after the brake is released, then the trailer brake control valve with a single-line drive does not resume air supply to the single-line line.

To check the completeness of air discharge from the control line, disconnect the heads in this line, close the disconnect valve and apply the parking or service brake on the tractor, and then release the brakes on the tractor.

After this, open the isolation valve in the control line; if air does not come out of the Palm head, the trailer brake control valve with a two-wire drive is working properly and will When the brakes are released, the air is completely released.

If air flows from the connecting head type “A” when the tractor is released, the single-wire line of the tractor is in good condition.

The reason for the lack of air in the trailer cylinder must be looked for on the trailer itself: it is necessary to check the condition of the main filter, dual-line valve, air distributor, pipelines.

So, for example, if the sealing washer in a two-line valve is leaking, air will pass through the valve into the supply line, and through the atmospheric outlet of a closed isolation valve in this line will escape into the atmosphere.

Air comes out of the atmospheric outlet of a single-line valve after braking - the valve itself is faulty (the diaphragm is broken or the upper thrust ring of the pusher or air distributor is broken).

Failure is easily detected when disconnecting the heads of a single-wire line or closing the isolation valve.

If the single-line valve continues to leak after this, the valve is faulty.

In case of leakage from the head with “B” or through the atmospheric outlet of a closed isolation valve, the air distributor must be repaired.

Consider the case when, when braking a road train operating on a single-line drive, the trailer brakes are activated with a delay and only after a significant amount of air has been released from the atmospheric outlet of the single-line valve.

The reason is the inconsistency between the pressure regulation in the single-line actuator (screw on the bottom of the single-line valve) and the equalizing valve (screw on the air distributor).

In this case, the closing pressure of the equalizing valve is less than the pressure in the single-line line and in the trailer cylinder.

When braking, the air from the trailer cylinder escapes until the equalizing valve closes, and the trailer brakes only after the valve closes.

If the closing pressure of the equalizing valve is greater than in a single-line line, then after switching from a two-wire drive to a single-line one, the pressure in the trailer cylinder will remain higher than in the single-line line, and such a trailer can only be released after reducing the pressure in the cylinder using condensate drain tap.