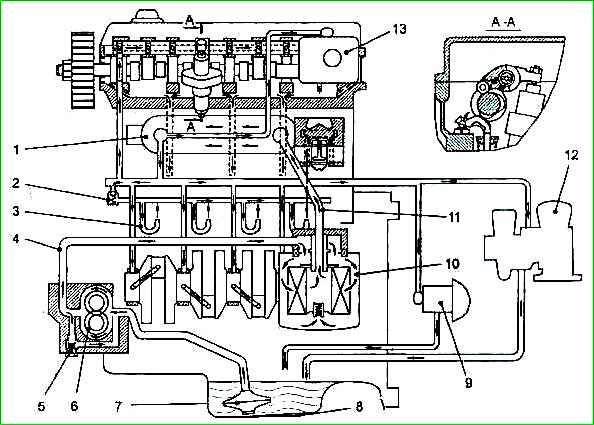

Combined lubrication system, pressure and splash

The lubrication system diagram is shown in the figure

Oil is supplied through hose 4 by gear oil pump 6 to oil filter 10, then through hose 11 to water-oil radiator 1 and then to the main oil line and to the servo drive of the fuel injection advance angle control mechanism (for GAZ-5602).

From the main oil line, oil is supplied to the crankshaft main bearings, connecting rod bearings, camshaft bearings, oil nozzles through the piston cooling valve (to cool the piston) and through a special fitting for lubrication of turbocharger 12 and vacuum pump 9.

The gear-type oil pump is driven by a gear mounted on the toe of the crankshaft. The pump contains a pressure reducing valve 5.

The pressure in the lubrication system should be:

- - at idle speed at least 100 kPa (1.0 kG/cm 2) at an oil temperature of 80-90° C;

- - at nominal speed (3800 rpm) within 500-700 kPa (5-7 kgf/cm 2).

A short-term reduction in oil pressure to 400 kPa (4 kgf/cm 2) is allowed for 5 minutes per 1 hour of operation.

Oil filter, non-separable, is designed to clean the oil supplied to the main oil line.

Water-oil radiator of sectional type, built into the engine cooling system and installed on a monoblock.

Maintenance of the GAZ-560 diesel lubrication system

The oil level is checked daily before starting the engine, and the vehicle must be parked on a level surface.

The oil level in the crankcase should be between the upper and lower marks on the level indicator (dipstick).

If the oil level reaches the lower mark, the oil must be added.

It is prohibited to operate the engine when the oil level is below the lower mark on the gauge.

After stopping the engine, check the oil no earlier than 5 minutes.

Changing the oil and oil filter

The oil change must be done on a hot engine; it takes at least 10 minutes to completely drain the oil.

At the same time as changing the oil, it is necessary to replace the oil filter.

It is recommended to use oil filters: Fleetguard LF3402 or LF3449, Knecht OS59 (F0371), Mann W940 or W940/15N, 560-1017005-02, 560-1017005-03.

When changing engine oil, use only the oil specified in this manual.

When replacing one brand of oil with another, flushing the engine is mandatory.

To flush the engine lubrication system you must:

- - drain the used oil from the crankcase of a warm engine;

- - fill in replacement oil or special flushing oil 2-4 mm above the upper mark on the level indicator;

- - start the engine and let it run at minimum crankshaft speed for at least ten minutes;

- - drain replacement oil or special flushing oil;

- - unscrew the used oil filter;

- - lubricate the rubber gasket of the new oil filter with engine oil and screw it in until the rubber gasket touches the seating surface on the filter housing, then tighten it another ¾ turn;

- - fill the engine with fresh oil.

Attention! When replacing high-pressure oil hoses, you must pay attention to the correct connection of them to the oil filter housing - there are arrows on the housing indicating the “input” from the oil pump to the filter and the “exit” from the filter to the oil cooler.

Incorrect connection will result in motor damage.